High-GWIT flame-retardant PBT/PC, and preparation method and application thereof

A technology of PBT resin and brominated flame retardant, which is applied in the field of engineering plastics, can solve the problems of insufficient mechanical properties such as toughness, and achieve excellent mechanical properties and heat resistance, good heat resistance, high flame retardancy and high toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

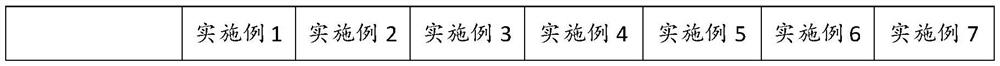

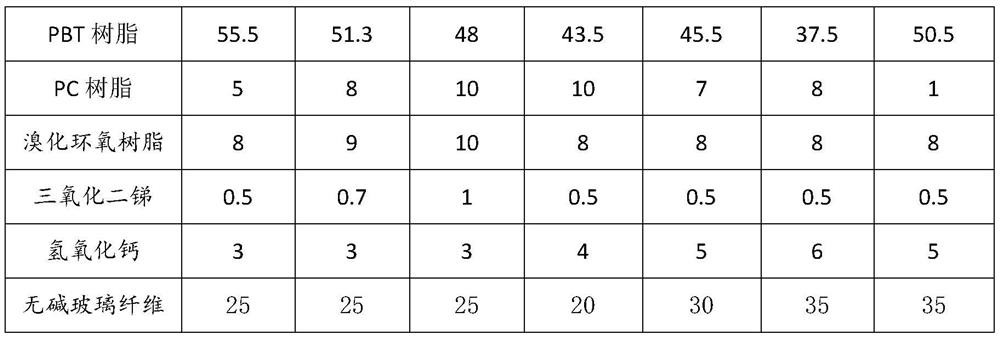

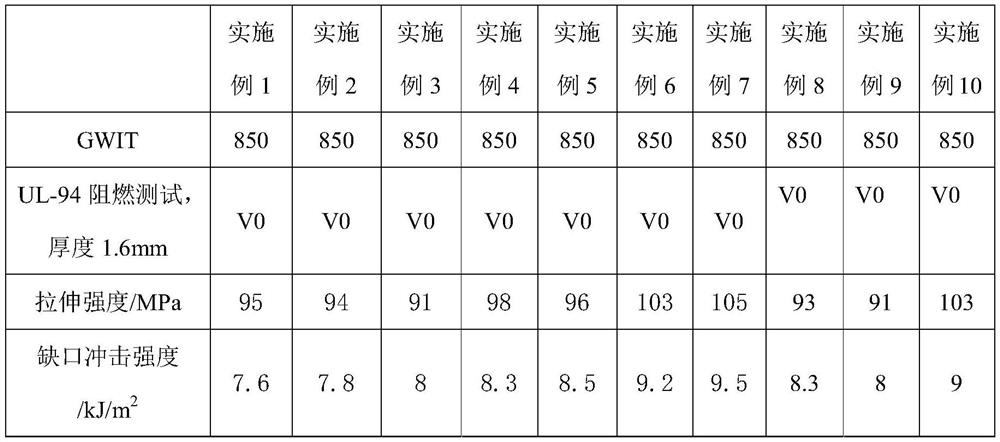

[0039] A high GWIT flame-retardant PBT / PC, including the components shown in Table 1 by weight percentage.

[0040] Among them, the relative density of PBT resin is 1.30-1.32g / cm 3 , melting point 215-230°C. Manufacturer: Taiwan Changchun Chemical Industry, Brand: PBT 1200-211M

[0041] The density of PC resin is 1.18-1.21g / cm3, and the melt index is 5-25g / 10min. Manufacturer: Korea LG Chem, Brand: PC 1300-22NP

[0042] The particle size of calcium hydroxide is 5 μm. commercially available.

[0043] Brominated flame retardants are brominated epoxy resins. Israel Chemical Group, Brand: Powder-F-2100

[0044] The preparation method of high GWIT flame retardant PBT / PC is as follows:

[0045] 1) Dry the PBT resin at 135°C for 4 hours and set aside;

[0046] 2) Mix PBT resin, PC resin, brominated flame retardant, antimony trioxide, and calcium hydroxide evenly, and add them to the twin-screw extruder. High GWIT flame retardant PBT / PC can be obtained by compounding, extruding...

Embodiment 8

[0051] A high GWIT flame-retardant PBT composition, by weight percentage, comprises the following components:

[0052] 45.5 parts of PBT resin

[0053] 7 parts PC resin

[0054] 8 parts brominated flame retardant

[0055] 0.5 parts of antimony trioxide

[0056] 5 parts calcium hydroxide

[0057] 30 parts of E-glass fiber.

[0058] Among them, the relative density of PBT resin is 1.30-1.32g / cm 3 , melting point 215-230°C.

[0059] The density of PC resin is 1.18~1.21g / cm 3 , Melt index 5 ~ 25g / 10min.

[0060] Brominated flame retardants are brominated epoxy resins.

[0061] Calcium hydroxide is calcium hydroxide having a particle diameter of 15 μm.

[0062] The preparation method of high GWIT flame retardant PBT / PC is as follows:

[0063] 1) Dry the PBT resin at 135°C for 4 hours and set aside;

[0064] 2) Mix PBT resin, PC resin, brominated flame retardant, antimony trioxide, and calcium hydroxide evenly, and add them to the twin-screw extruder. High GWIT flame ret...

Embodiment 9

[0066] A high GWIT flame-retardant PBT composition, by weight percentage, comprises the following components:

[0067] 45.5 parts of PBT resin

[0068] 7 parts PC resin

[0069] 8 parts brominated flame retardant

[0070] 0.5 parts of antimony trioxide

[0071] 5 parts calcium hydroxide

[0072] 30 parts of E-glass fiber.

[0073] Among them, the relative density of PBT resin is 1.30-1.32g / cm 3 , melting point 215-230°C.

[0074] The density of PC resin is 1.18~1.21g / cm 3 , Melt index 5 ~ 25g / 10min.

[0075] Brominated flame retardants are brominated epoxy resins.

[0076] Calcium hydroxide is calcium hydroxide having a particle diameter of 10 μm.

[0077] The preparation method of high GWIT flame retardant PBT / PC is as follows:

[0078] 1) Dry the PBT resin at 135°C for 4 hours and set aside;

[0079] 2) Mix PBT resin, PC resin, brominated flame retardant, antimony trioxide, and calcium hydroxide evenly, and add them to the twin-screw extruder. High GWIT flame ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com