Asphalt for tunnel pavement and preparation method thereof

A technology of pavement and asphalt, which is applied in the field of new modified asphalt materials, can solve the problems of influence, unfavorable low-temperature crack resistance of asphalt, and little contribution to high-temperature stability of asphalt, so as to improve durability, reduce maintenance cycle, and improve resistance. The effect of burning and suppressing smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

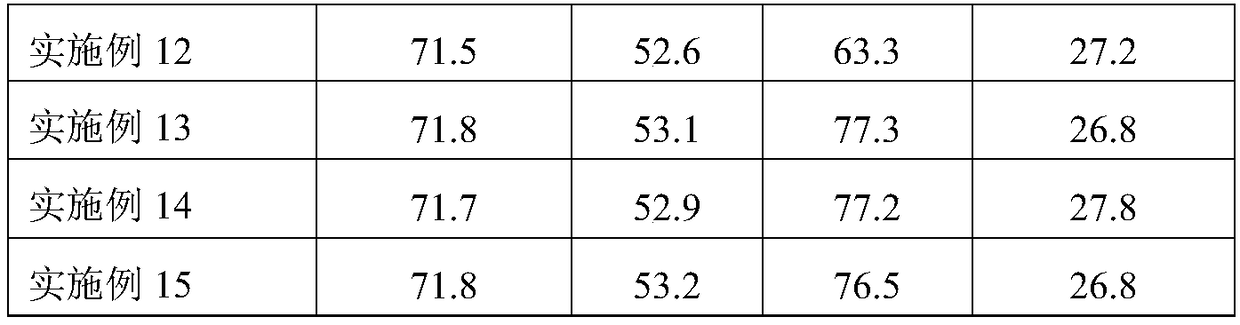

Examples

preparation example Construction

[0031] A preparation method for tunnel pavement asphalt, specifically comprising the following steps:

[0032] Step 1), first heating the base asphalt to a molten state, then adding organic rectorite and composite additives in the molten base asphalt and stirring to obtain mixture A;

[0033] Step 2), polyurethane prepolymer and anti-aging agent are mixed to obtain mixture B, mixture B is added in mixture A and mixed uniformly to obtain mixture C;

[0034] Step 3), finally adding the flame retardant to the mixture C, and mixing evenly to obtain the required tunnel pavement asphalt.

[0035] Further, in step 1), the base asphalt is heated to a molten state at 130°C-160°C, and then the organic rectorite and composite additives are sequentially added to the melted base asphalt, stirring at 1000-2000r / min during the addition process Stir at high speed; in the process of adding compound additives, add in small amounts several times in order to stir evenly;

[0036] In step 2), in...

Embodiment 1

[0039] Step 1. Heat 500g of asphalt to 135°C, slowly add 5g of organic rectorite at a stirring speed of 2000r / min, then add 0.5g of maleic anhydride and 2.5g of aromatic diamine chain extender and stir for 2min to obtain mixture A ;

[0040] Step 2. At a stirring rate of 2000r / min, slowly add a mixture B of 25g polyurethane prepolymer and 0.05g tetraerythritol ester at 90°C to mixture A, and keep stirring at 135°C for 10min at 2000r / min to obtain mixture C;

[0041] Step 3, finally add 1.25g dimethyl methylphosphonate at 1000r / min, continue to keep the temperature and speed and stir for 2min to obtain modified asphalt.

Embodiment 2

[0043] Step 1. Heat 500g of asphalt to 130°C, slowly add 7g of organic rectorite at a stirring speed of 1000r / min, then add 0.7g of maleic anhydride and 3.5g of aromatic diamine chain extender and stir for 5min to obtain mixture A ;

[0044] Step 2. At a stirring rate of 2000r / min, slowly add a mixture B of 35g polyurethane prepolymer and 0.1g antioxidant 1010 at 90°C to mixture A, and keep stirring at 135°C for 10min at 2000r / min to obtain mixture C;

[0045] Step 3, finally add 1.75g dimethyl methylphosphonate at 1000r / min, continue to keep the temperature and speed and stir for 2min to obtain modified asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com