A kind of preparation method and product of multilevel layered gradient material

A gradient material and layered technology, applied in the field of preparation of multi-level layered gradient materials, can solve the problems of limited strength/toughness matching optimization effect, inability to apply thicker materials, etc., and achieve excellent strength-toughness matching and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

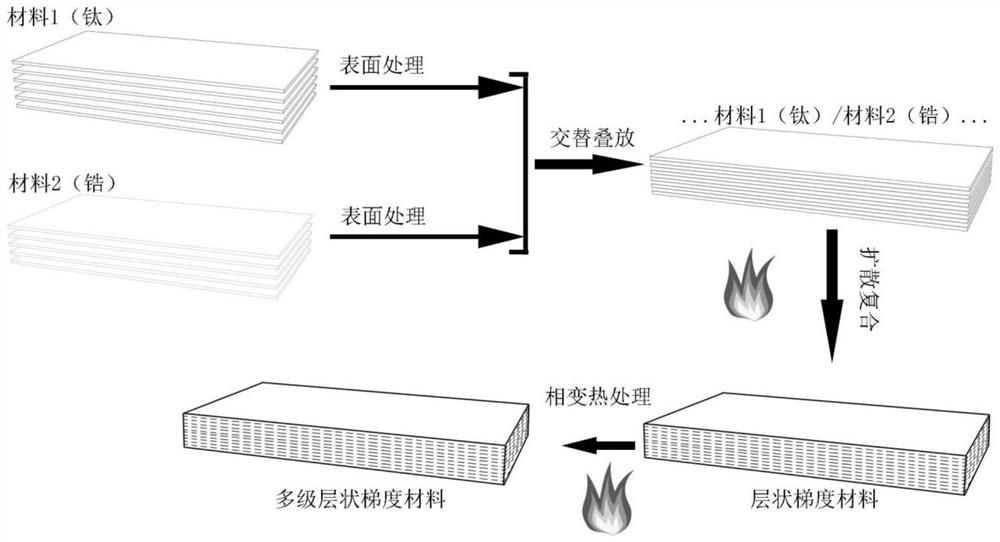

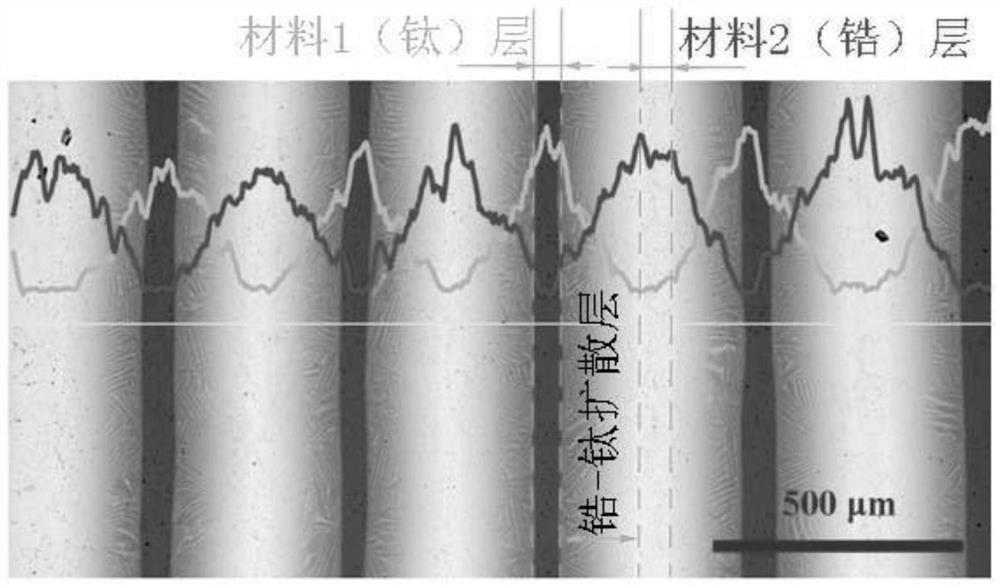

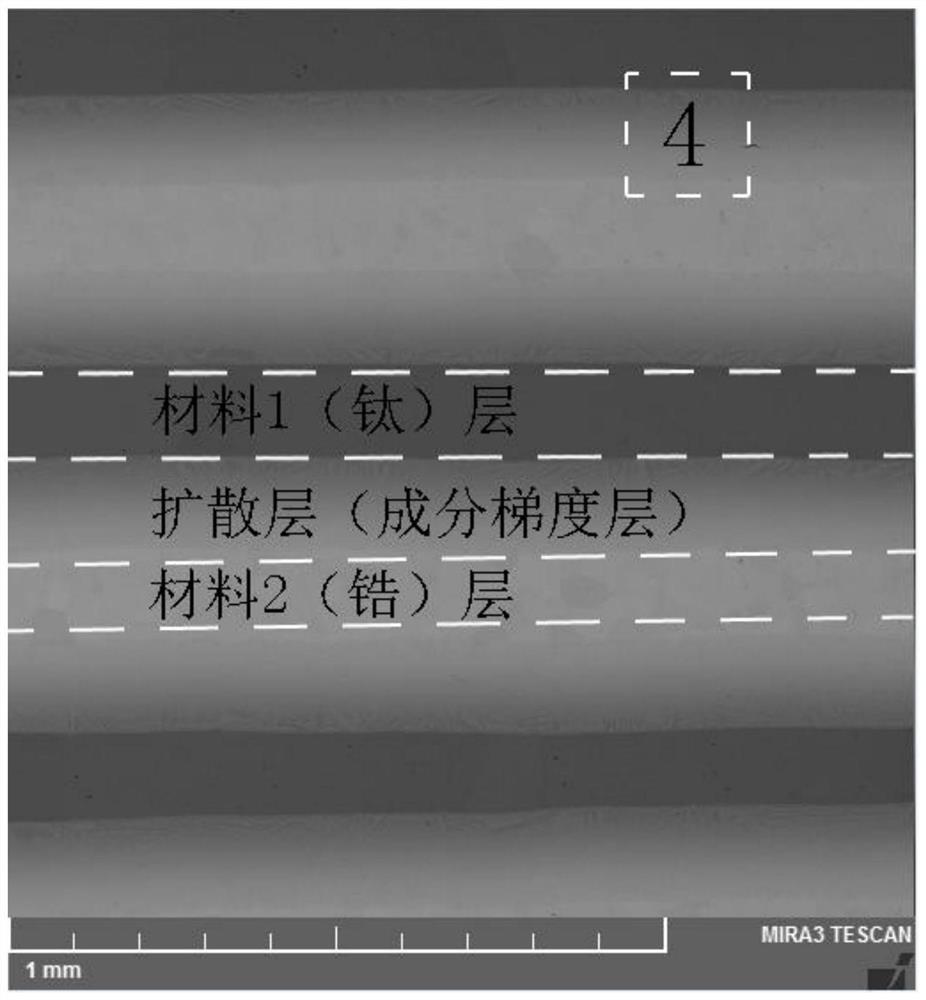

[0028] A preparation method of a multi-level layered gradient material, comprising the following steps: 1) selecting pure titanium and pure zirconium two metals, the preparation flow chart of which is as follows figure 1 shown. Zirconium and titanium can be dissolved infinitely, and the stable phase of the formed solid solution is a body-centered cubic structure at high temperature, while the stable phase at room temperature or lower temperature is a close-packed hexagonal structure. The allotropic phase transition temperature is related to the solid solution composition, and the phase transition temperature ranges from 605°C to 882°C; 2) Surface treatment is carried out for the selected metal materials (pure titanium and pure zirconium) to obtain a clean sample surface. These surface-treated metal materials were cut into matching sizes (100 mm long x 25 mm wide x 0.5 mm thick in this example), and stacked alternately (6 pieces of pure titanium and 5 pieces of pure zirconium)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com