A medium-entropy alloy material and application method for additive manufacturing

A technology of additive manufacturing and application methods, applied in the field of additive manufacturing, can solve the problems of poor toughness matching of high-entropy alloys, difficulty in maintaining the original structure, and difficulty in realizing industrialization, etc., to achieve low cost and prevent the formation of brittle intermediate phases , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

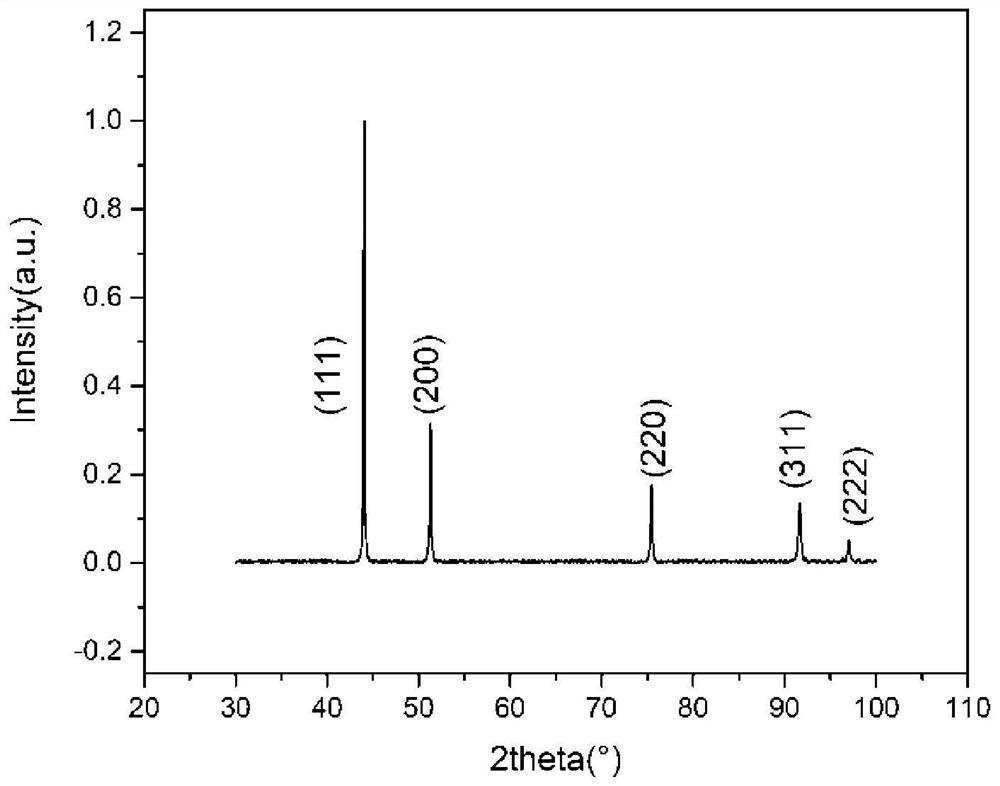

Image

Examples

Embodiment 1

[0031] The powdered medium entropy alloy with a particle size of 0-25 μm is used, and the drug powder formula is Cr50%, Co30%, Ni20%, and the additive manufacturing is carried out. The steps are as follows:

[0032] Step 1) Select a 115mm×115mm stainless steel substrate and clean it until it is clean, free of oil, dust, rust, etc.;

[0033] Step 2) Use an industrial robot to carry a laser, and connect the laser cladding powder feeding system for the selected area in parallel. Dry and sieve the powder and fill it into the powder spreading system, and at the same time, the scraper in the powder spreading system spreads the first layer of powder on the substrate;

[0034] Step 3) Establish a 3D model of a cube array with a side length of 20mm to be printed in the software, convert it into a robot scanning path file, and input it into the robot control computer;

[0035] Step 4) Scan with a given path at a scanning speed of 800mm / s, a scanning distance of 0.03mm, a power of 160W,...

Embodiment 2

[0039] In this example, a powdered medium-entropy alloy with a particle size of 15-53 μm is used, and the powder formula is Cr33%, Co33%, and Ni34%, for additive manufacturing. The steps are as follows:

[0040] Step 1) Select a 115mm×115mm stainless steel substrate and clean it until it is clean, free of oil, dust, rust, etc.;

[0041] Step 2) Use an industrial robot to carry a laser, and connect the laser cladding powder feeding system for the selected area in parallel. Dry and sieve the powder and fill it into the powder spreading system, and at the same time, the scraper in the powder spreading system spreads the first layer of powder on the substrate;

[0042] Step 3) Establish a 3D model of a cylindrical array with a radius of 5mm and a height of 10mm to be printed in the software, convert it into a robot scanning path file, and input it into the robot control computer;

[0043] Step 4) According to the scanning speed of 1000mm / s, the scanning distance of 0.04mm, the po...

Embodiment 3

[0047] In this example, a powdered medium-entropy alloy with a particle size of 53-150 μm is used. The powder formula is Cr20%, Co50%, and Ni30%, and the additive manufacturing is carried out. The steps are as follows:

[0048] Step 1) Select a titanium substrate of 200mm×150mm, and clean it until it is clean, free of oil, dust, rust, etc.;

[0049] Step 2) Use an industrial robot to carry a laser, and connect the selected area laser cladding powder feeding system in parallel, dry and sieve the alloy powder and fill it into the powder feeding system;

[0050] Step 3) Establish a 3D model of a cube array with a side length of 20 mm to be printed in the software, convert it into a robot scanning path file, and input it into the robot control computer;

[0051] Step 4) According to the scanning speed of 700mm / s, the scanning distance of 3.0mm, the power of 3500W, the laser spot diameter of 2mm, and the layer thickness of 0.5mm, scan with a given path to form a molten pool; at the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com