Low-alloy wear-resistant steel with good bending formability and production method thereof

A technology of bending forming and production method, which is applied to low-alloy wear-resistant steel with good bending forming performance and its production field, which can solve the problem of restricting the application range of high-end low-alloy wear-resistant steel products, and is not suitable for ultra-high-strength martensitic steel. The problems of body wear-resistant steel and other problems are achieved, and the effect of fine microstructure, excellent bending and forming performance, and good strength and toughness is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

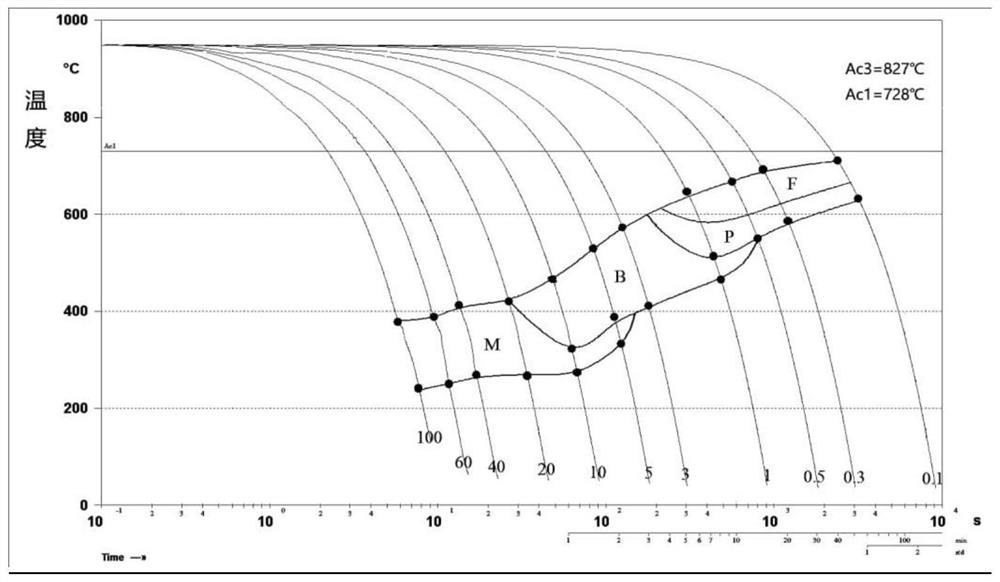

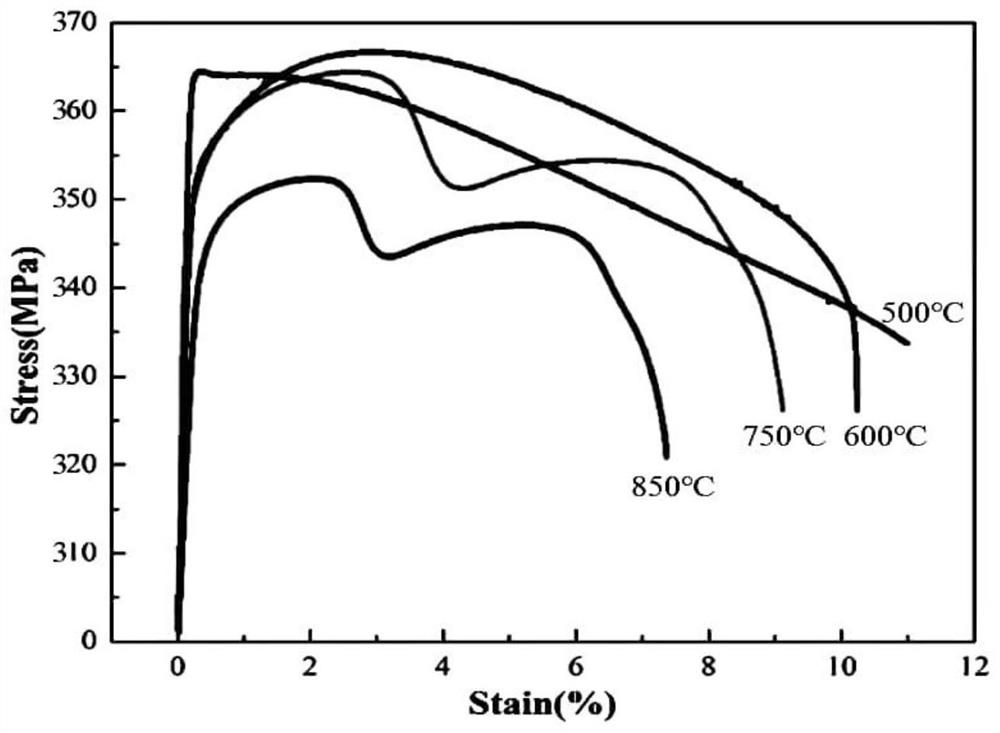

[0037] The core control process of the present invention is based on the following: (1) at first utilize the DIL805L phase change dilatometer to measure the phase transition laws of different isothermal times and different cooling rates of the composition system, and the experimental results are shown in Table 1, figure 1 As shown in Table 1, figure 1 It shows that the Ac3 (full austenitization temperature of the steel plate) is 827°C. In order to ensure the full and uniform austenitization of the steel plate in the thickness direction and length direction, the quenching heat treatment heating and holding temperature is 30°C to 60°C above Ac3, and the cooling rate reaches Martensitic transformation begins at 20°C / s, and the martensite transformation temperature is 415°C. As the cooling rate increases, the martensite transformation temperature gradually decreases from 415°C to 379°C, and the martensite transformation temperature The end temperature is gradually reduced from 246...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com