A Design Method of Hypersonic Inner Parallel Three-Channel Inlet Regulating Mechanism

A hypersonic, adjusting mechanism technology, applied in mechanical equipment, gas turbine devices, machines/engines, etc., can solve the problems of increased design difficulty and structural complexity of air intake control, and achieves light weight, simple and practical structure, and solves the problem of starting effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

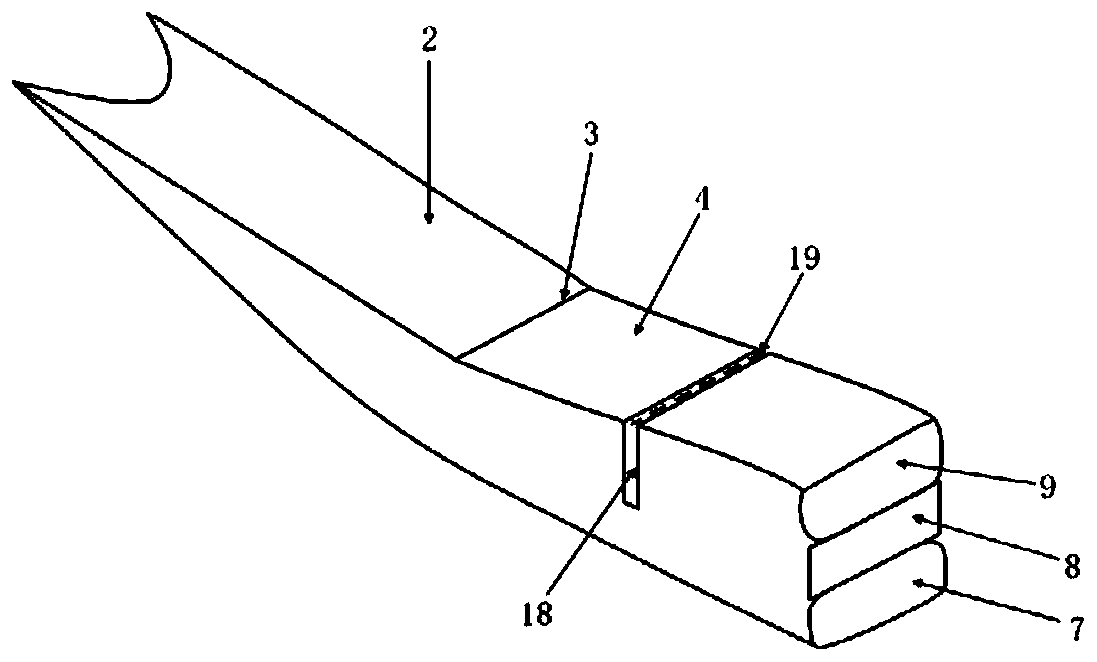

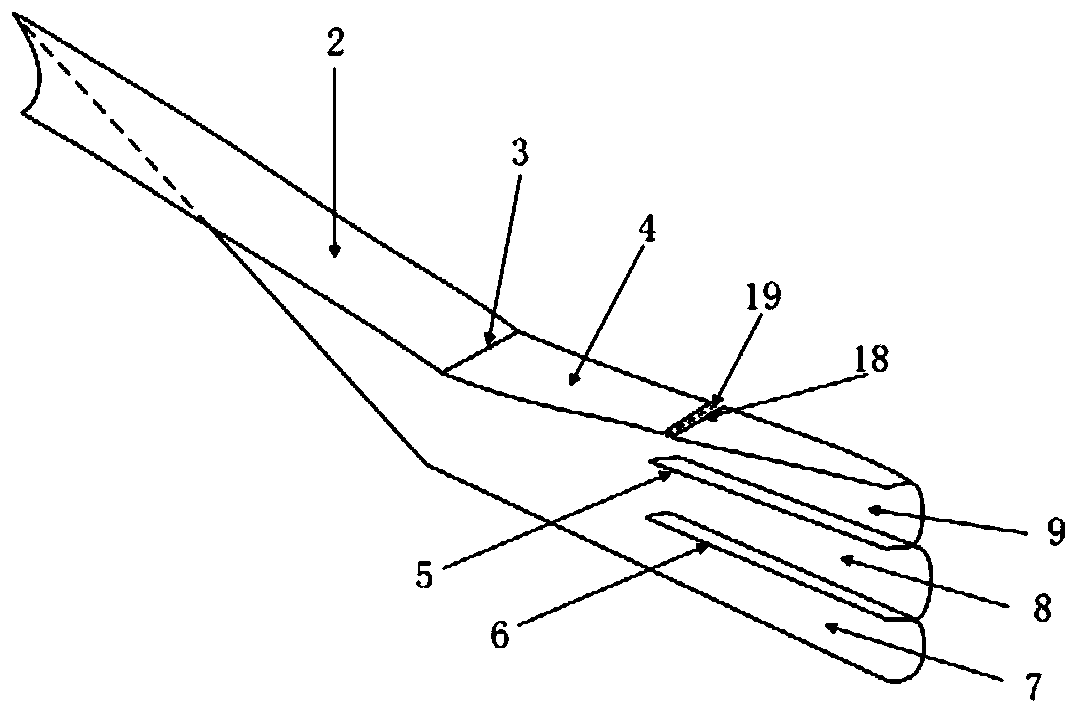

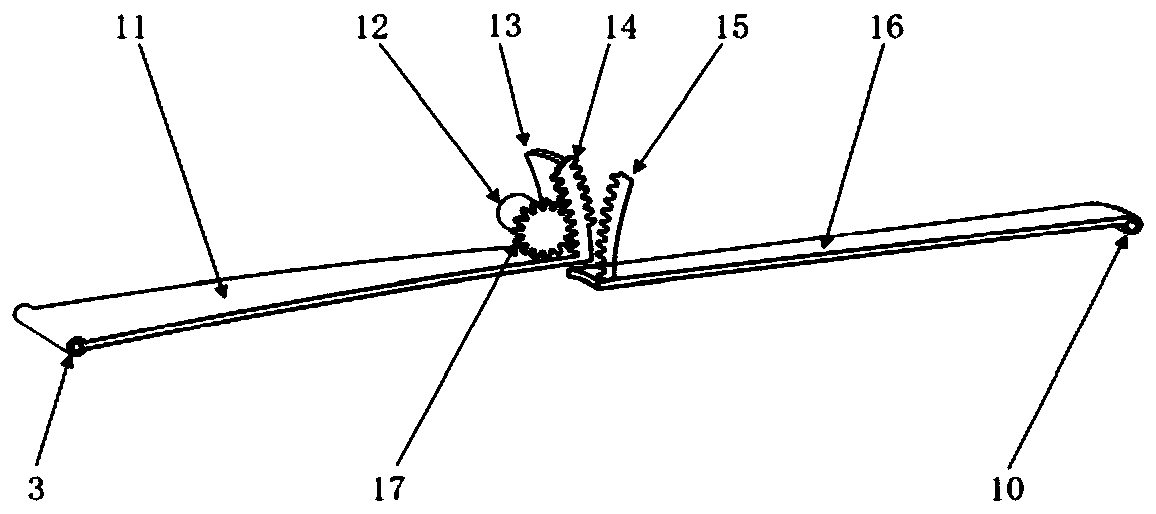

[0026] Such as figure 1 and 2 As shown, the hypersonic internal parallel three-channel inlet includes an external pressure section 2, a rotating shaft 3, a splitter section 4, a turbine channel 9, a rocket channel 8, a ram channel 7, and a partition 5 between the turbine channel and the rocket channel , the partition plate 6 between the rocket channel and the stamping channel, the baffle plate groove 18 on the wall surface of the air inlet. Such as image 3 As shown, the hypersonic internal parallel three-channel inlet adjustment mechanism includes a rotating shaft 3, a main splitter plate 11, a motor 12, a baffle plate 13, a driving rack 14, a driven rack 15, an auxiliary splitter plate 16 and a rotary spring 10, Wherein, the main splitter plate 11 , the driving rack 14 is connected with the baffle plate 13 , and the auxiliary splitter plate 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com