Multi-heat source waste heat recovery system

A waste heat recovery system and multi-heat source technology, applied in the direction of heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of huge size, affecting the effect of waste heat utilization, and many recovery equipment, so as to save energy and improve comprehensive Use efficiency to realize the effect of self-production and self-sale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

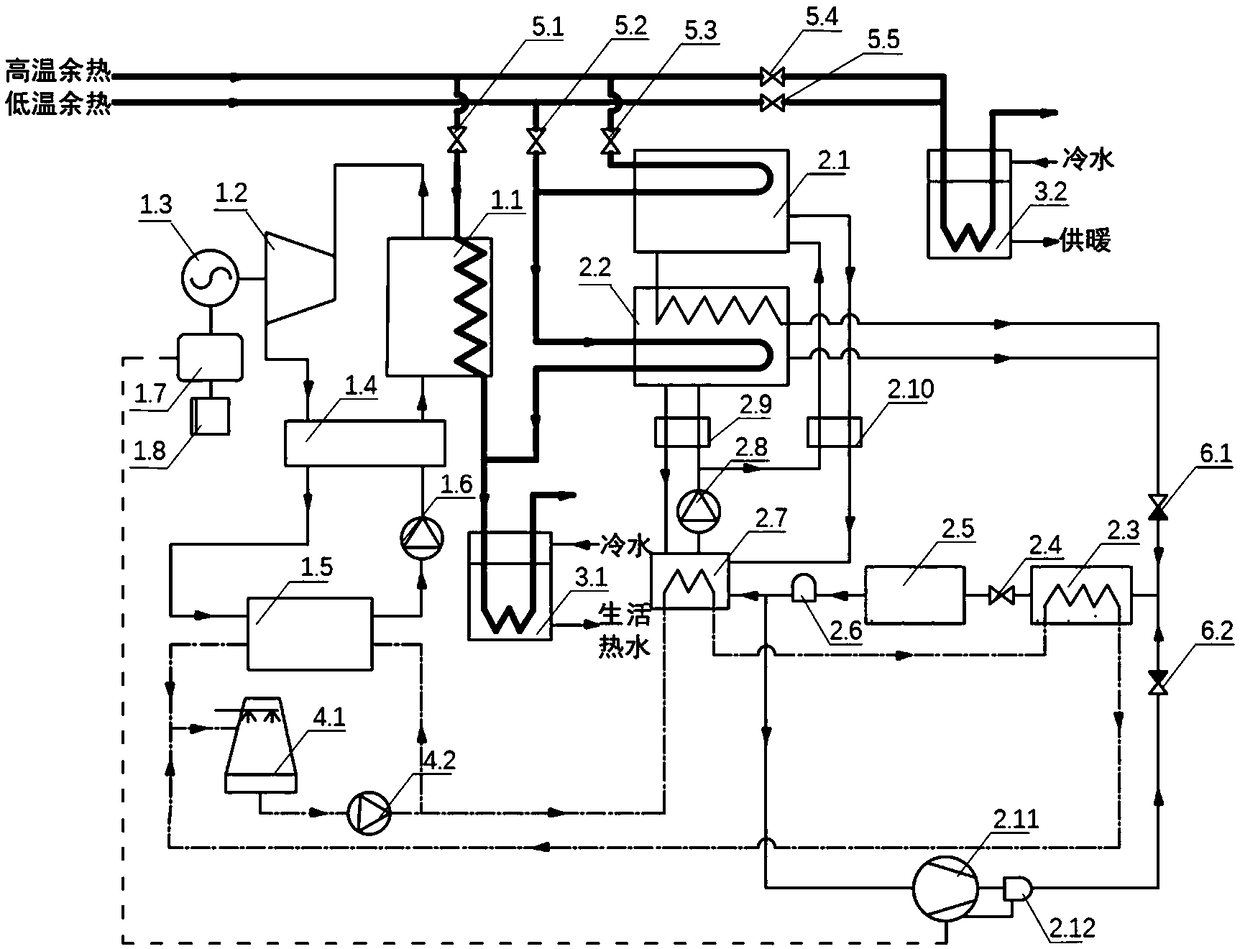

[0017] like figure 1 As shown, a multi-heat source waste heat recovery system of the present invention includes a power generation system, a refrigeration system, a heating system and a cooling system.

[0018] Power generation system: including sequentially connected evaporator I1.1, turbine 1.2, regenerator 1.4, condenser I1.5, working medium pump 1.6, turbine 1.2 is connected to generator 1.3, generator 1.3 is connected to controller 1.7, The controller 1.7 is connected to the battery 1.8 and the compressor 2.11, the condenser I1.5 is connected to the cooling system, and the evaporator I1.1 is connected to the low-temperature water storage tank 3.1 of the heating system. The evaporator I1.1 is connected to the high-temperature waste heat through the valve I5.1.

[0019] The internal circulating working medium of the power generation system is an organic working medium,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com