Method for preparing ammonium chloride and light magnesium carbonate from phosphate tailings and recycling ammonium chloride and light magnesium carbonate

A technology of light magnesium carbonate and ammonium chloride is applied in the field of waste resource utilization, which can solve the problems of low added value of products and low utilization rate of phosphorus tailings, so as to improve comprehensive utilization efficiency and facilitate industrialization promotion. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In an embodiment, the raw ore chemical composition of phosphate rock is: P 2 o 5 : 6.5%, MgO: 13.1%, CaO: 31.9%.

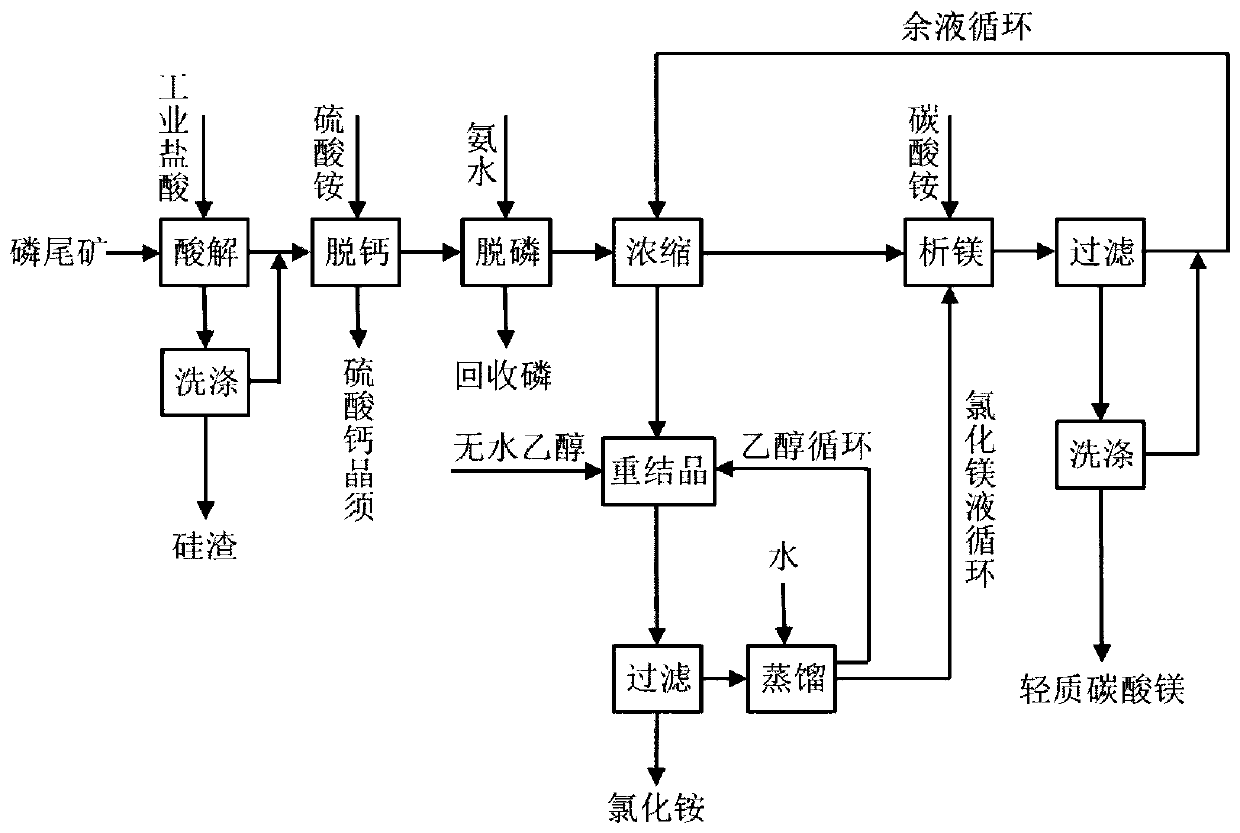

[0034] combine figure 1 As shown, the method of utilizing phosphorus tailings to prepare ammonium chloride and light magnesium carbonate and recycling in the present embodiment specifically includes the following steps:

[0035] 1) Weigh 100g of phosphorus tailings and put it into the acidolysis reactor, add 232mL of tap water and heat up to 40°C, slowly add 232mL of industrial hydrochloric acid with a mass fraction of 35%, after acidolysis for 25 minutes, heat-preserve and suction filter, and wash The silicon slag obtained by suction filtration obtains the acid solution A;

[0036] 2) The ratio of ammonium sulfate and the amount of calcium ion in the above-mentioned acid solution A is 1: 1 to configure the ammonium sulfate solution with a mass fraction of 30%, and add the configured ammonium sulfate solution to the reactor Raise the temperature to 70°C...

Embodiment 2

[0043] In an embodiment, the raw ore chemical composition of phosphate rock is: P 2 o 5 : 3.8%, MgO: 14.2%, CaO: 35.8%.

[0044] combine figure 1 As shown, the method of utilizing phosphorus tailings to prepare ammonium chloride and light magnesium carbonate and recycling in the present embodiment specifically includes the following steps:

[0045] 1) Weigh 90g of phosphorus tailings and put it into an acidolysis reactor, add 195mL of tap water and heat up to 50°C, slowly add 232mL of industrial hydrochloric acid with a mass fraction of 35%, and after acidolysis for 35 minutes, heat-preserve and suction filter, and wash The silicon slag obtained by suction filtration obtains the acid solution A;

[0046]2) The ratio of ammonium sulfate and the amount of calcium ion in the above-mentioned acid solution A is 1.2: 1. The mass fraction is 40% ammonium sulfate solution, and the configured ammonium sulfate solution is added to the reactor Raise the temperature to 80°C, then slow...

Embodiment 3

[0053] In an embodiment, the raw ore chemical composition of phosphate rock is: P 2 o 5 : 8.5%, MgO: 13.8%, CaO: 40.5%.

[0054] combine figure 1 As shown, the method of utilizing phosphorus tailings to prepare ammonium chloride and light magnesium carbonate and recycling in the present embodiment specifically includes the following steps:

[0055] 1) Weigh 82g of phosphorus tailings and put it into the acidolysis reactor, add 170mL of tap water and heat up to 60°C, slowly add 232mL of industrial hydrochloric acid with a mass fraction of 35%, and after acidolysis for 45 minutes, heat-preserve and suction filter, and wash The silicon slag obtained by suction filtration obtains the acid solution A;

[0056] 2) Ammonium sulfate solution with a mass fraction of 55% is configured in an amount of 1.4:1 in the ratio of ammonium sulfate to the amount of calcium ion in the above-mentioned acid solution A, and the configured ammonium sulfate solution is added to the reactor Raise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com