System for obtaining asphalt and building sand from oil sand

A bitumen and oil sand technology, applied in the system field of obtaining bitumen and construction sand, can solve the problems of difficult tailings treatment, environmental pollution, large water consumption, etc., and achieve the effect of improving resource utilization efficiency and comprehensive utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

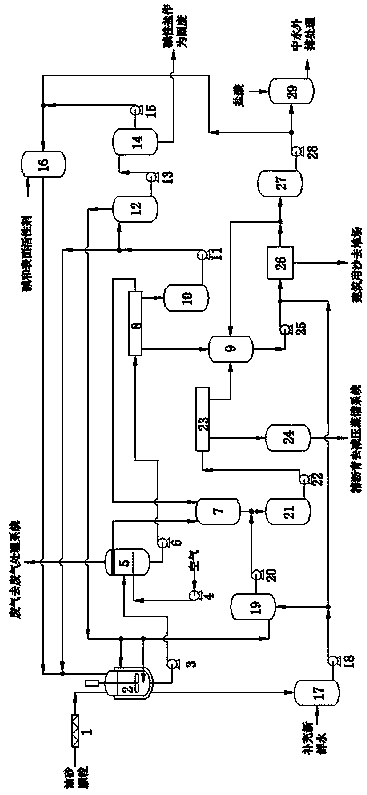

[0011] A system for obtaining bitumen and sand for construction from oil sands, including screw conveyor (1), extraction tank (2), flotation tank (5), crude bitumen storage tank (7), three-phase centrifuge (8 ), sand-water mixing tank (9), stock solution tank (10), evaporator (12), crystallization tank (14), batching tank (16), clear water tank (17), water heating tank (19), asphalt washing tank (21), two-phase centrifuge (23), refined bitumen storage tank (24), plate and frame filter press (26), waste water tank (27), neutralization tank (29) and related centrifugal pumps, air pumps and connections The pipelines of the above equipment; the extraction kettle (2) is a jacketed stirred tank, the top of which is provided with a solid feed port and a liquid feed port, the bottom is provided with a discharge port and a steam inlet, and the jacket layer is provided with a steam inlet and a steam inlet. Condensed water outlet; the top of the flotation tank (5) is provided with an exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com