A method for designing oil-gas lubrication of high-speed electric spindle rolling bear

A technology of high-speed electric spindle and oil-air lubrication, which is applied to shafts and bearings, bearing components, calculations, etc., can solve problems such as invention patent reports on oil-air lubrication system design technology that have not yet been seen, and reduce operating temperature rise and prolong service life. , Improve the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The design technology of the high-speed electric spindle rolling bearing oil-air lubrication system of the present invention will be further described in detail below in conjunction with an embodiment (the design of the high-speed electric spindle steel ball bearing 7006C and the hybrid ceramic ball bearing B7006C oil-air lubrication system).

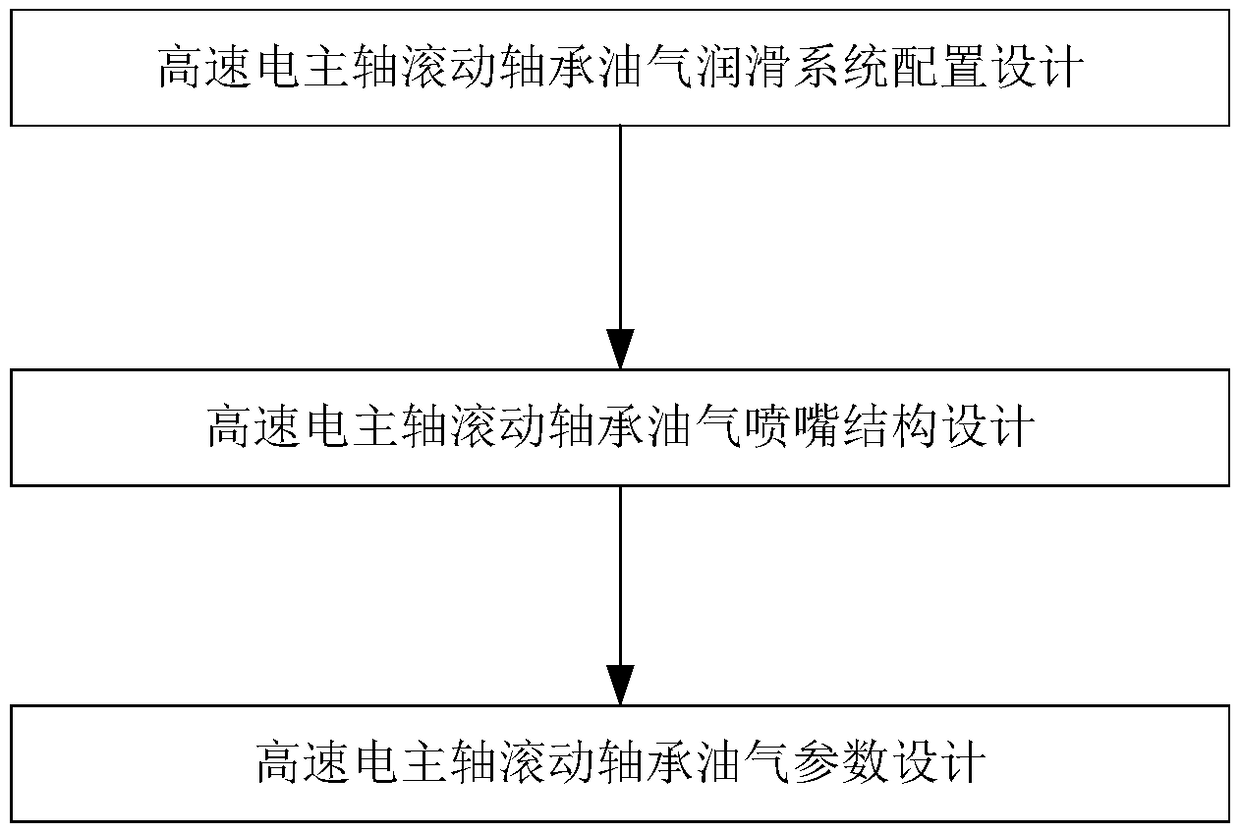

[0032] figure 1 The specific content of the design technology of the high-speed electric spindle rolling bearing oil-air lubrication system of the present invention is given, including the following steps:

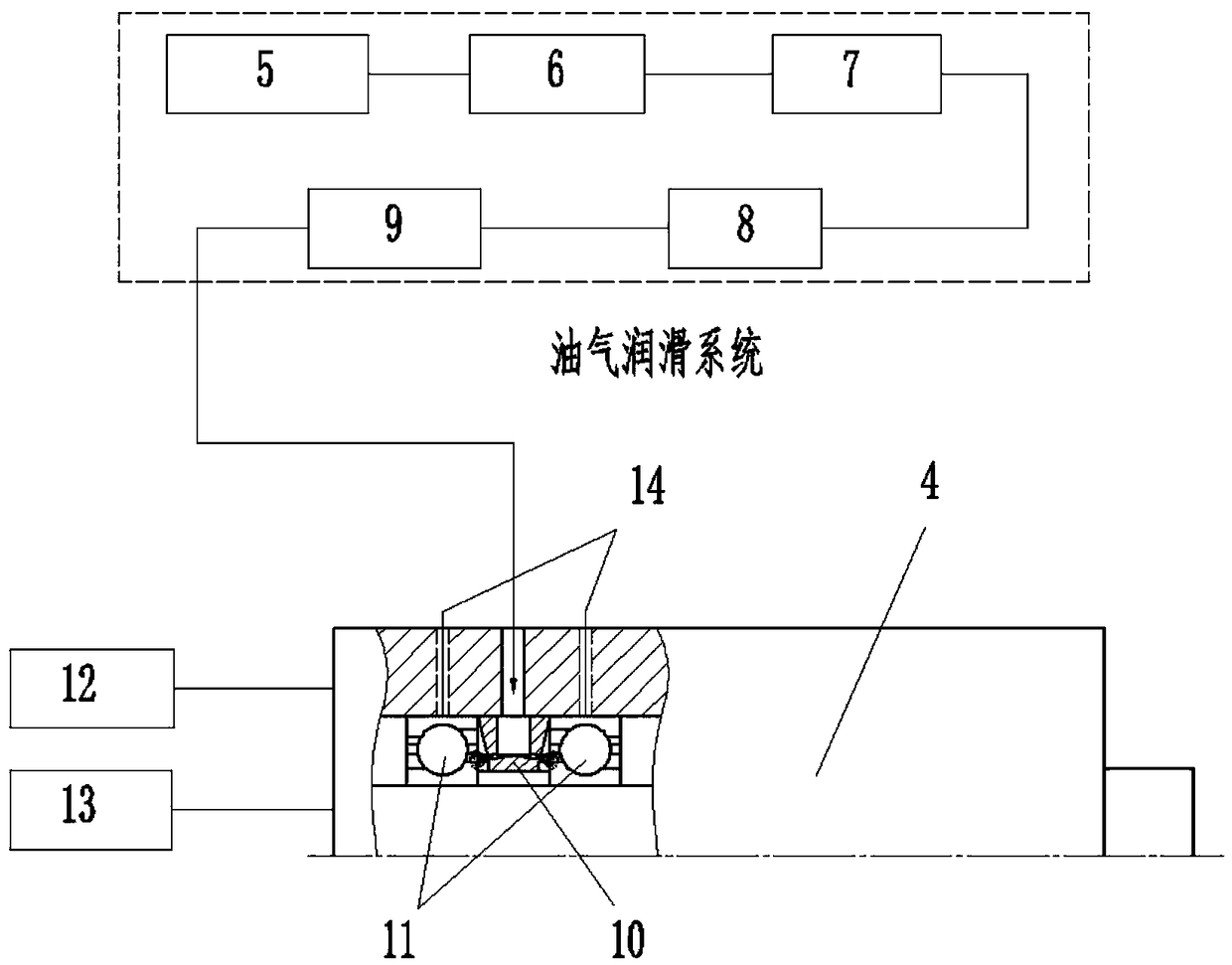

[0033] Step 1: Configuration design of oil-air lubrication system for rolling bearing of high-speed electric spindle. Such as figure 2 As shown, the air compressor 5 continuously provides compressed air, and the compressed air reaches the air storage tank 7 after passing through the three-stage filter 6 to remove impurities (dust, particles), and then passes through the cold dryer 8 to remove water vapor, and flows through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com