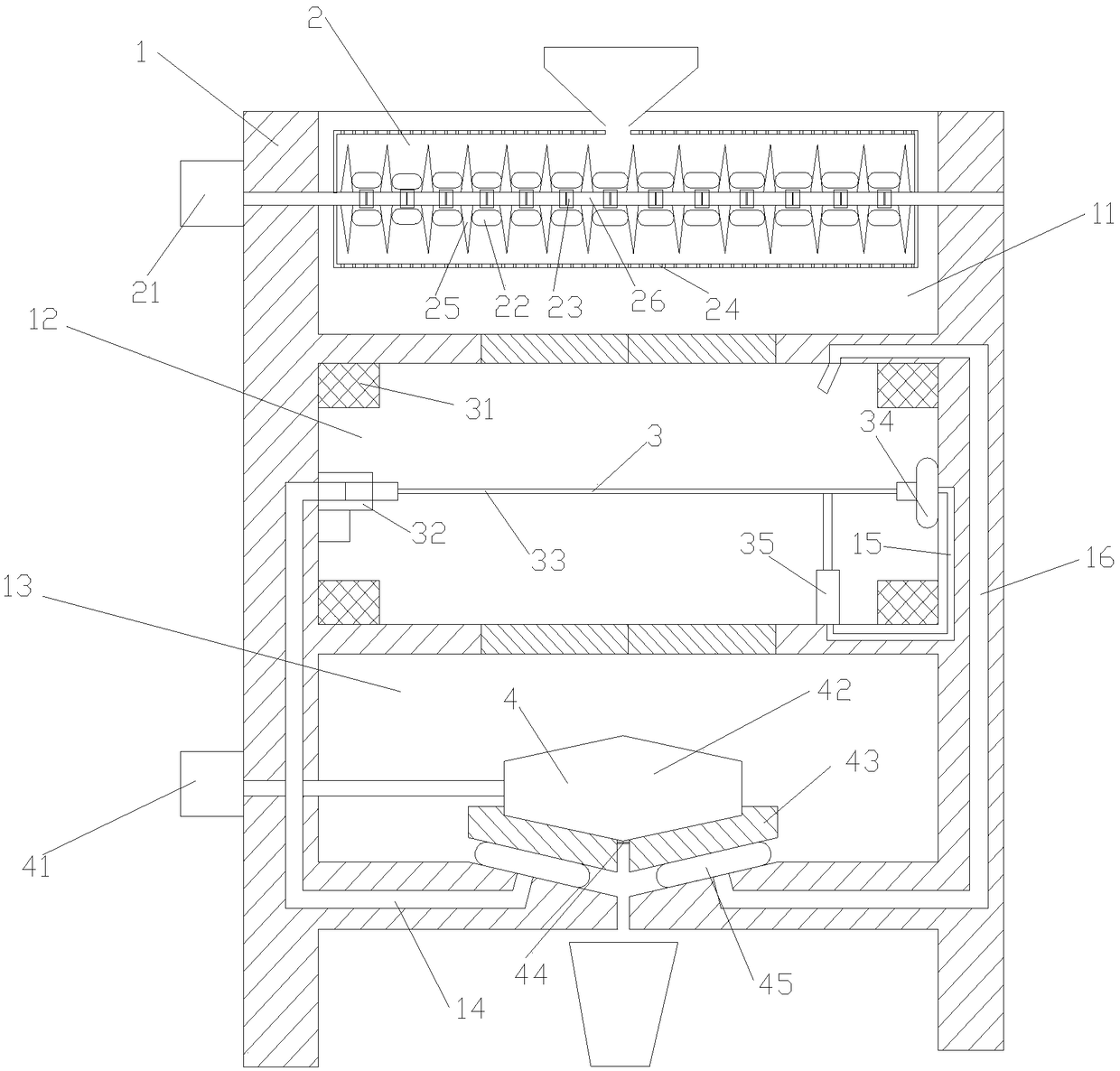

Marine alga food processing system

A food processing and processing system technology, applied in food processing, grain processing, food science, etc., can solve the problems of algae easily entangled in the dehydration mechanism, uneven and insufficient drying, poor dehydration effect, etc., to achieve uniform distribution of algae, improve Grinding effect, the effect of improving the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

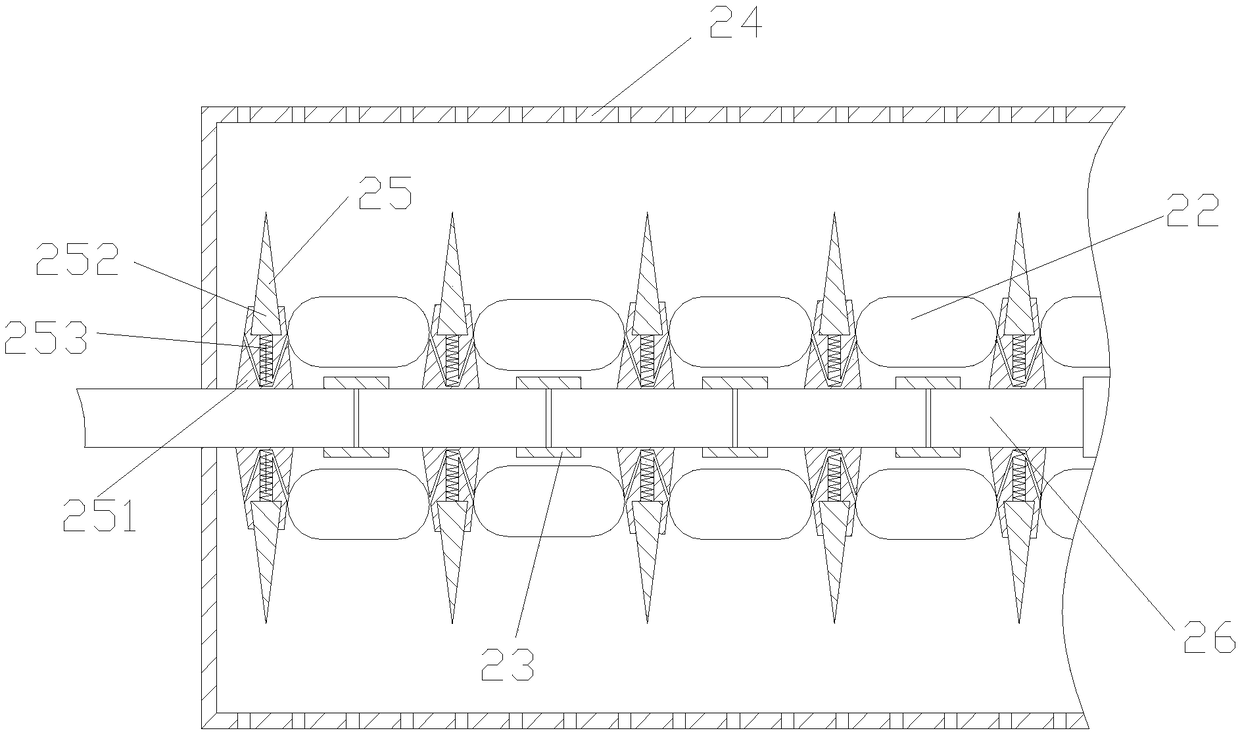

[0029] As an embodiment of the present invention, the pneumatic centrifugal spring knife 25 includes a knife seat 251, a knife tooth 252 and a spring 253; The air bag 22 air holes are connected, and the other end is connected to the counterbore of the knife holder 251; one end of the spring 253 is fixed in the counterbore, and the other end is connected with the knife tooth 252, and when the rotating shaft rotates, the spring 253 stretches the knife tooth 252 and ejects due to centrifugal force. When cutting hard objects, due to the flexible connection of the rubber connecting block 23 between the connecting shafts 26, deformation will occur, and the No. 1 airbag 22 will be squeezed. After the No. 1 airbag 22 is squeezed, the gas will enter the pneumatic centrifugal spring knife 25, and the spring 253 Further stretching, the knife teeth 252 stretch out further, and hard objects are shredded.

[0030] As an embodiment of the present invention, the material used for the knife to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com