A zirconia denture with gradient mechanical properties and its manufacturing method

A manufacturing method and technology of zirconia, applied in ceramic products, household appliances, other household appliances, etc., can solve the problems of natural tooth wear, low fracture toughness, high hardness, etc., and achieve improved life expectancy, excellent performance, and comprehensive performance improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

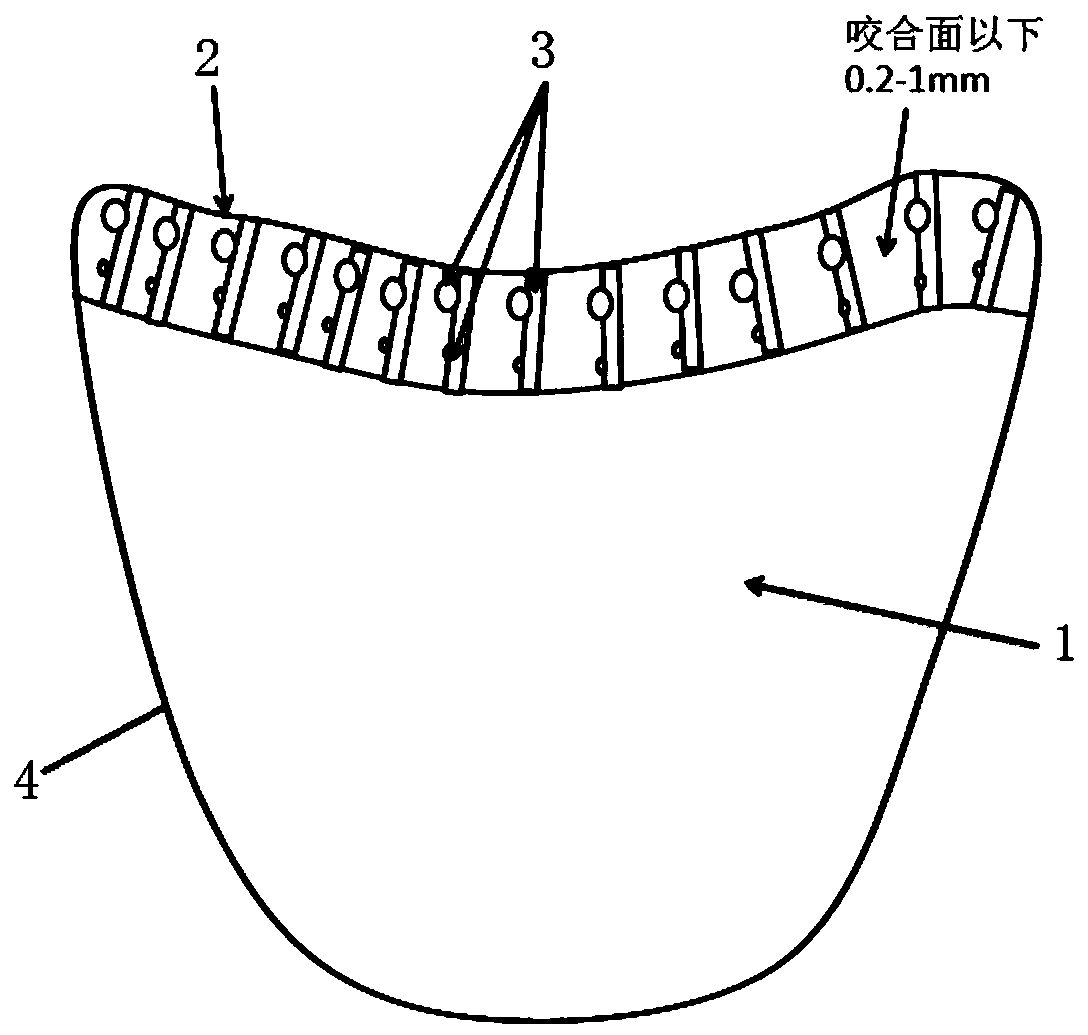

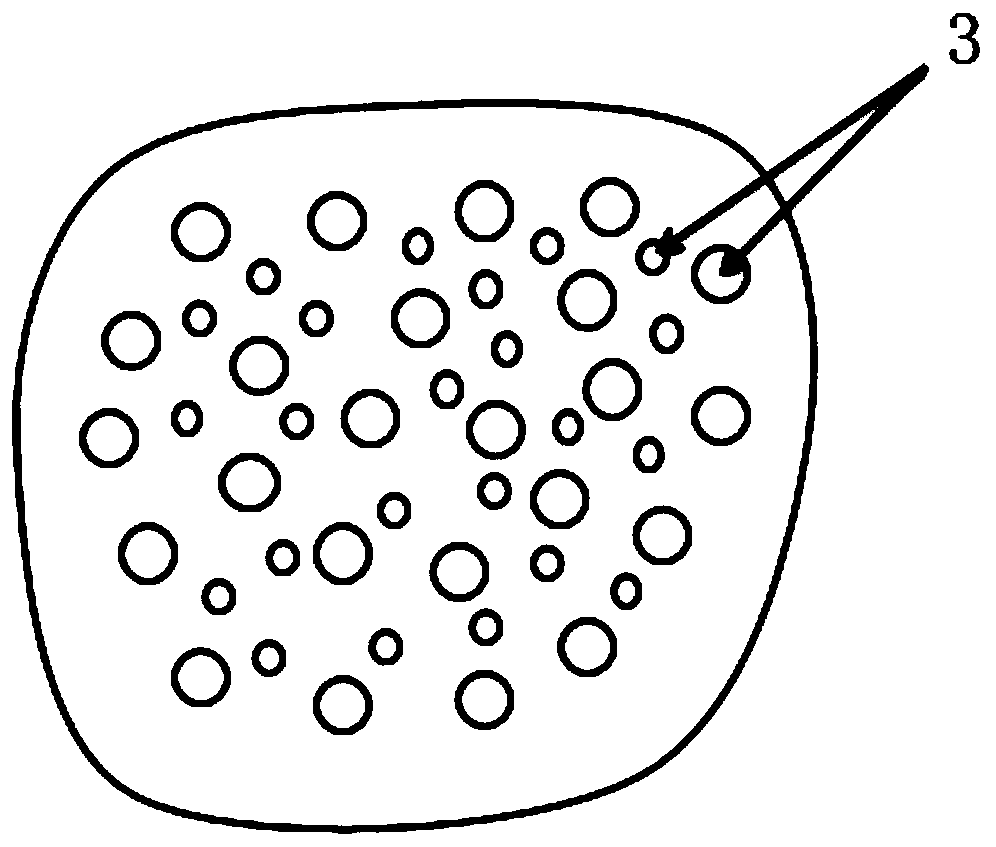

Embodiment 1

[0045] Use mimics software to carry out three-dimensional reconstruction of CT data, 3-matic software design pore size, porosity and pore arrangement according to mechanical performance requirements and installation requirements, and then use Cura slice software to slice layer thickness, exposure time of each layer and other parameters Set up, adding support structures if necessary. Take 15mL of trimethylolpropane triacrylate and 5mL of ethoxylated pentaerythritol tetraacrylate as photocurable resin monomers; weigh 0.99g of Tego 685 dispersant, 0.11g of polymerization inhibitor MQ, and 0.22g of leveling agent, 0.22g defoamer and 0.22g graphite dye. The resin monomer and various additives were evenly mixed, and ball milled in a ball mill at a speed of 800 rpm / min for 4 hours to obtain a premixed liquid. Then weigh 33g of zirconia powder (particle size 100 μm) and 1.1g of photoinitiator diacylphosphine oxide 819, and ball mill at a speed of 800rpm / min for 2h in a ball mill to o...

Embodiment 2

[0047] Use mimics software to perform three-dimensional reconstruction of CT data. Magics software designs pore size, porosity and pore arrangement according to mechanical performance requirements and installation requirements, and then uses Cura slice software to set slice layer thickness, exposure time of each layer and other parameters. Add support structures as necessary. Take 15mL of trimethylolpropane triacrylate and 5mL of ethoxylated pentaerythritol tetraacrylate as photocurable resin monomers; weigh 6.2g of Tego 685 dispersant, 0.44g of polymerization inhibitor MQ, and 1.1g of leveling agent, 1.1g defoamer and 1.1g graphite dye. The resin monomer and various additives were evenly mixed, and ball milled in a ball mill at a speed of 1000 rpm / min for 6 hours to obtain a premixed liquid. Take again 32g of zirconia powder (100 μm in particle size), and ball mill it for 2 h at a speed of 1000 rpm / min in a ball mill; then weigh 1.1 g of photoinitiator diacylphosphine oxide ...

Embodiment 3

[0049] Use mimics software to perform three-dimensional reconstruction of CT data. Magics software designs pore size, porosity and pore arrangement according to mechanical performance requirements and installation requirements, and then uses Cura slice software to set slice layer thickness, exposure time of each layer and other parameters. Add support structures as necessary. Take 15mL of trimethylolpropane triacrylate and 5mL of ethoxylated pentaerythritol tetraacrylate as photocurable resin monomers; weigh 3.4g of Tego 685 dispersant, 0.25g of polymerization inhibitor MQ, and 0.62g of leveling agent, 0.62g defoamer and 0.62g graphite dye. The resin monomer and various additives were evenly mixed, and ball milled in a ball mill at a speed of 1000 rpm / min for 6 hours to obtain a premixed solution. Take again 62g of zirconia powder (100 μm in particle size), and ball mill it for 2 h at a speed of 1000 rpm / min in a ball mill; then weigh 2.2g of photoinitiator diacylphosphine ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com