Pipe-shell type heat exchanger pipe penetrating guiding device

A shell-and-tube heat exchanger and guide technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of inability to accurately and quickly guide the next hole, affecting the assembly efficiency of the heat exchanger, and the position of the heat exchange tube. Skew and other issues to ensure accuracy, simple structure, and accurate guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

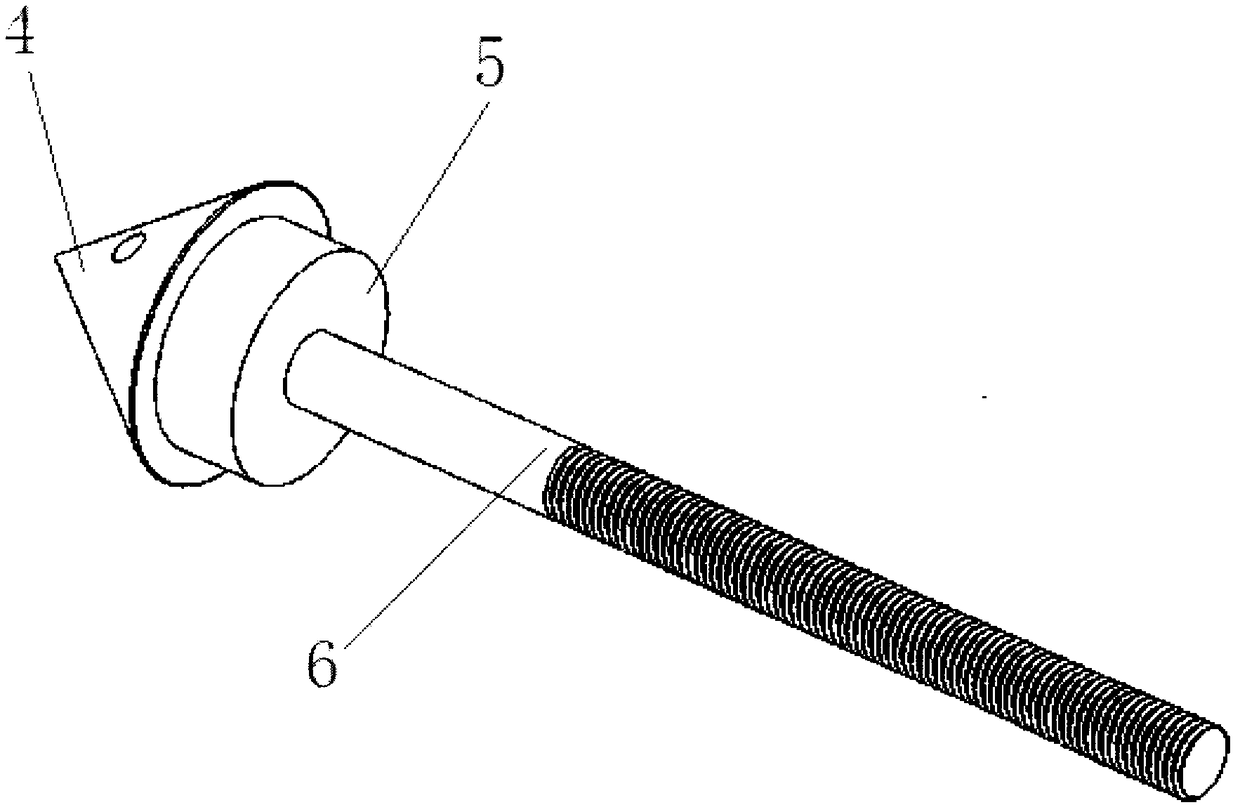

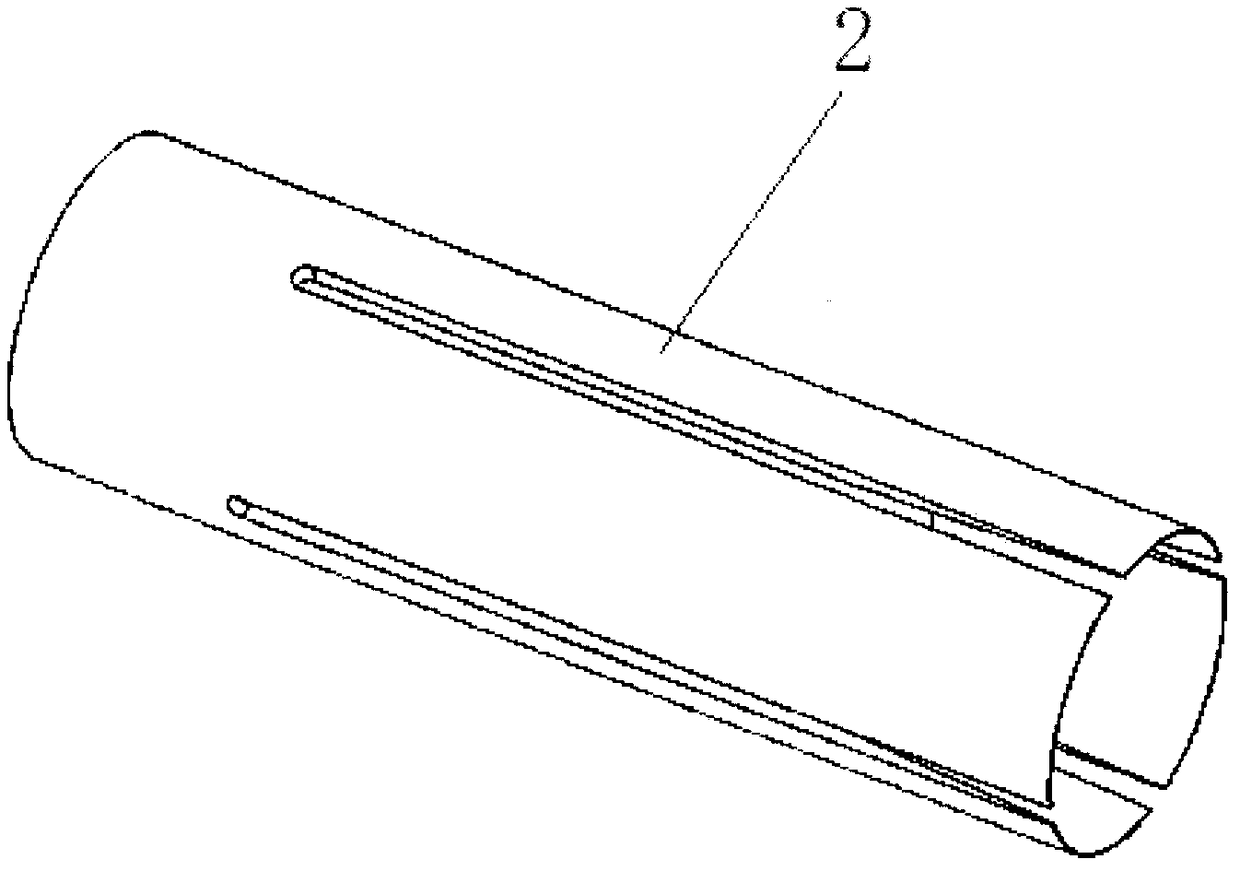

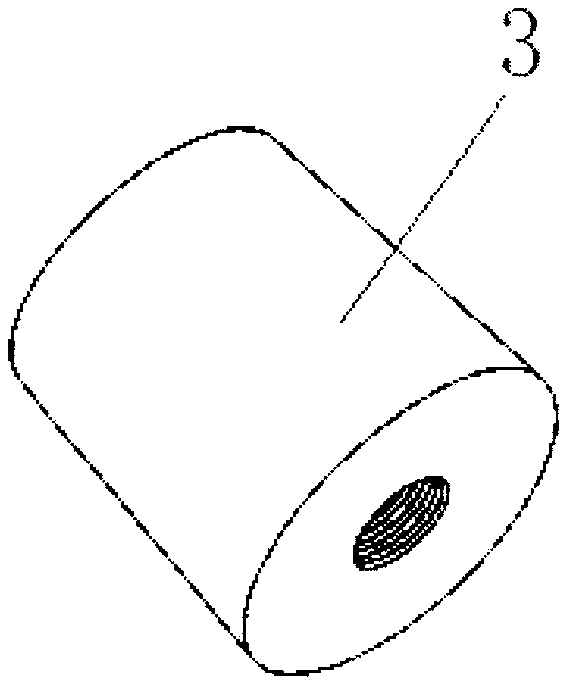

[0019] Such as Figure 5 As shown, the present invention includes a guide head 1, a sleeve 2 and an expansion plug 3, figure 1 A schematic diagram of the guide head structure, figure 2 A schematic diagram of the sleeve structure, image 3 For the structural schematic diagram of the expansion plug, the present invention is installed at first, as Figure 4 , put the sleeve 2 on the outside of the guide head 1, rely on the surface of the cone 4 at the front end of the guide head 1 and the surface of the middle cylinder 5, and then screw the expansion plug 3 into the thread at the tail of the guide rod 6, as shown Figure 5 .

[0020] Concrete working principle of the present invention is as follows:

[0021] In order to give full play to the rapid guiding function of the present invention, ensure the accurate introduction of the heat exchange tubes, and at the same time prevent the penetration force from causing the inner wall wear caused by the relative movement of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com