A riveting tool and riveting method suitable for aircraft composite material vertical tail wing box

A technology of composite materials and vertical fins, which can be applied to household appliances, other household appliances, household components, etc., can solve problems such as inability to reset, large product structure size, and difficult installation of fasteners, so as to achieve a wide range of applications and improve product quality , the effect of reducing the impact of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

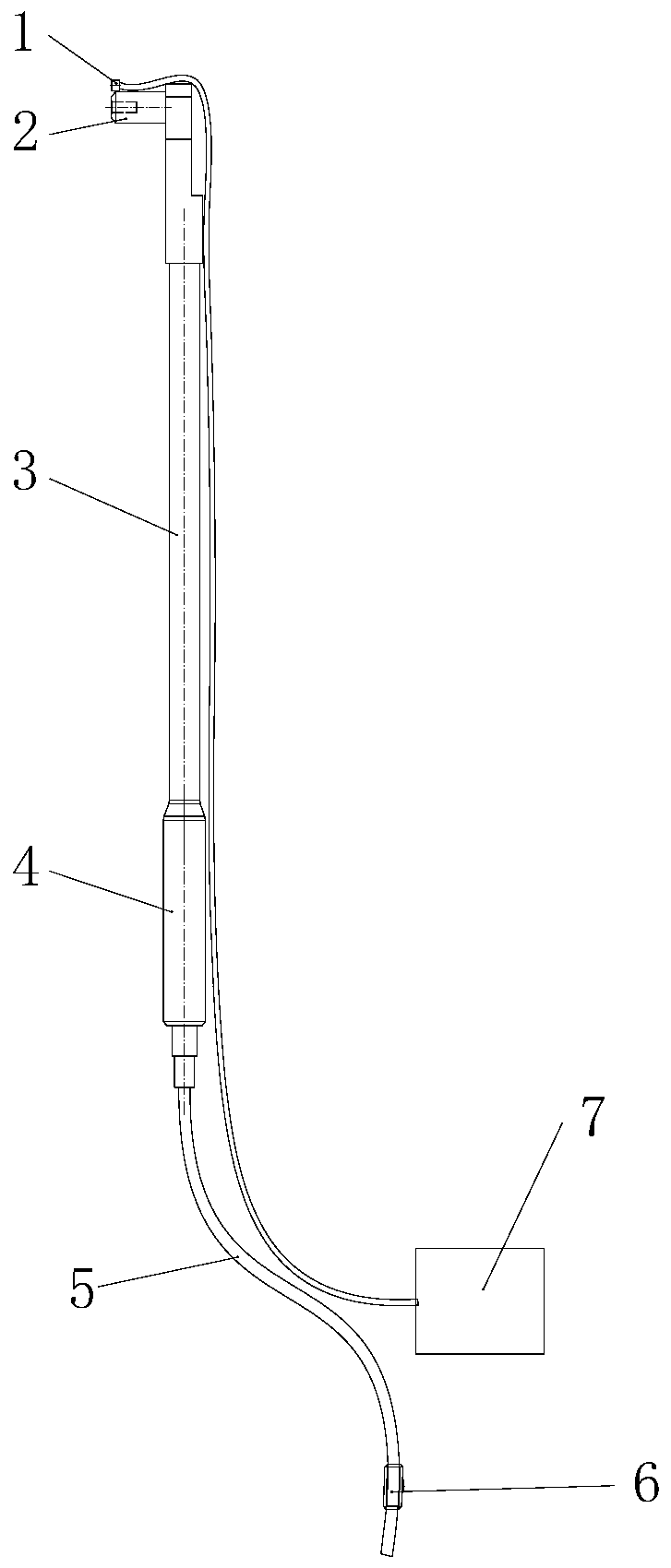

[0026] Such as figure 1 and figure 2 As shown, a riveting tool suitable for aircraft composite material vertical tail wing box, including endoscope lens 1, magnetic chuck 2, extension tube 3, handle 4, air duct 5, wind control switch 6 and display screen 7 .

[0027] The handle 4 is connected to the extension tube 3, the extension tube 3 is connected to the magnetic chuck 2, one end of the air duct 5 is connected to the air control switch 6, and the other end passes through the handle 4 and the extension tube 3 to communicate with the magnetic chuck 2, and the endoscope lens 1 is installed on the magnetic chuck 2, and the endoscope lens 1 is connected with the display screen 7 through a line.

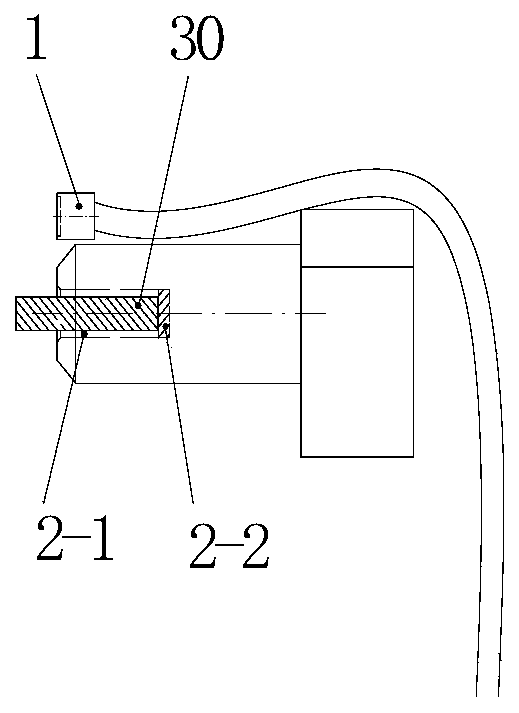

[0028] The magnetic chuck 2 is provided with a groove 2-1, and a permanent magnet 2-2 is arranged in the groove 2-1.

Embodiment 2

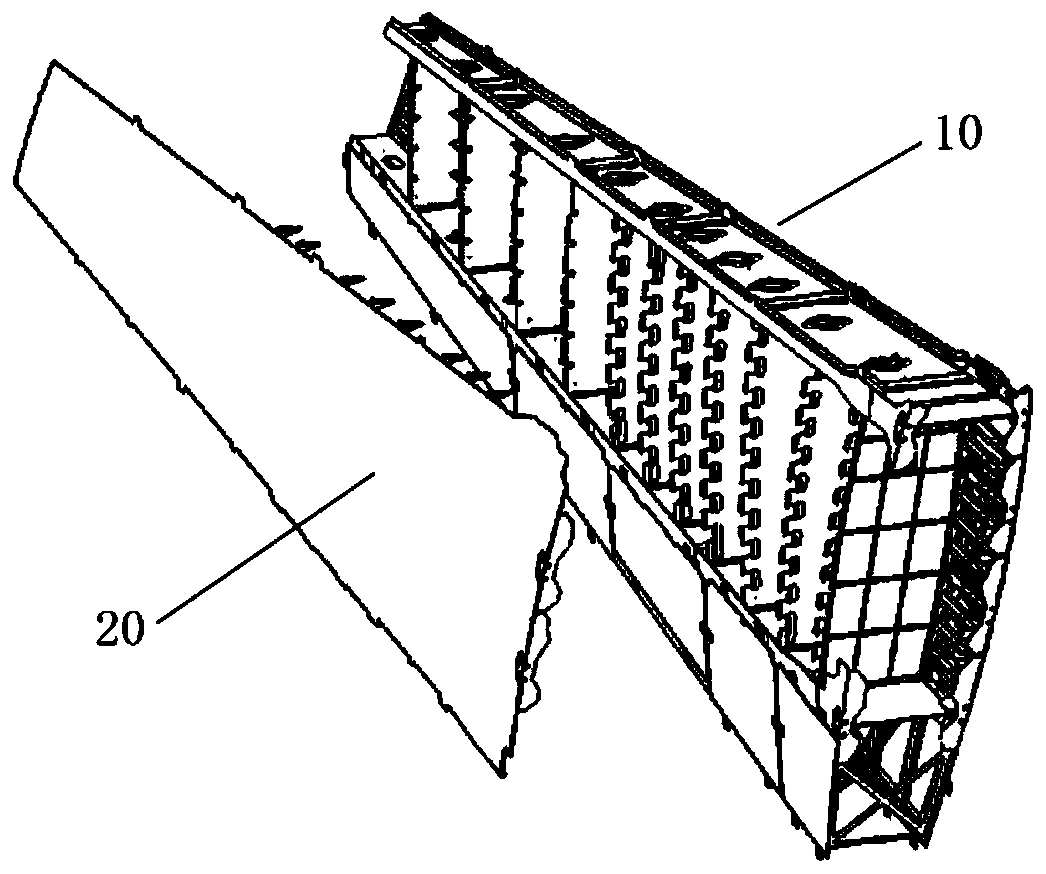

[0030] During the aircraft assembly process, the aircraft vertical tail wing box consists of the right side wall panel I10 and the left side wall panel II20 to form a "closed box section". A "lightening hole" 40 is provided on the beam at the lower end of the "closed box section". The interior of the "closed box section" of the wing box is supported by ribs, all of which are composite materials. At the joint between the ribs and the girders, connecting corner pieces are designed to strengthen the structural strength. There are 82 corner pieces in total. There are 2 fasteners that need to be installed in an enclosed space.

[0031] A kind of riveting method that is suitable for aircraft composite material vertical empennage box, utilizes the sealing riveting tool that is suitable for aircraft composite material vertical empennage of embodiment 1, comprises the steps:

[0032] 1) if image 3 As shown, the two panels that constitute the aircraft composite material vertical tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com