Automatic cleaning equipment and cleaning method for passenger car power cabin

An automatic cleaning and power cabin technology, applied in the direction of vehicle exterior cleaning devices, etc., can solve the problems of loud noise, scattered dust and damage to the internal components of the power cabin at the cleaning site. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

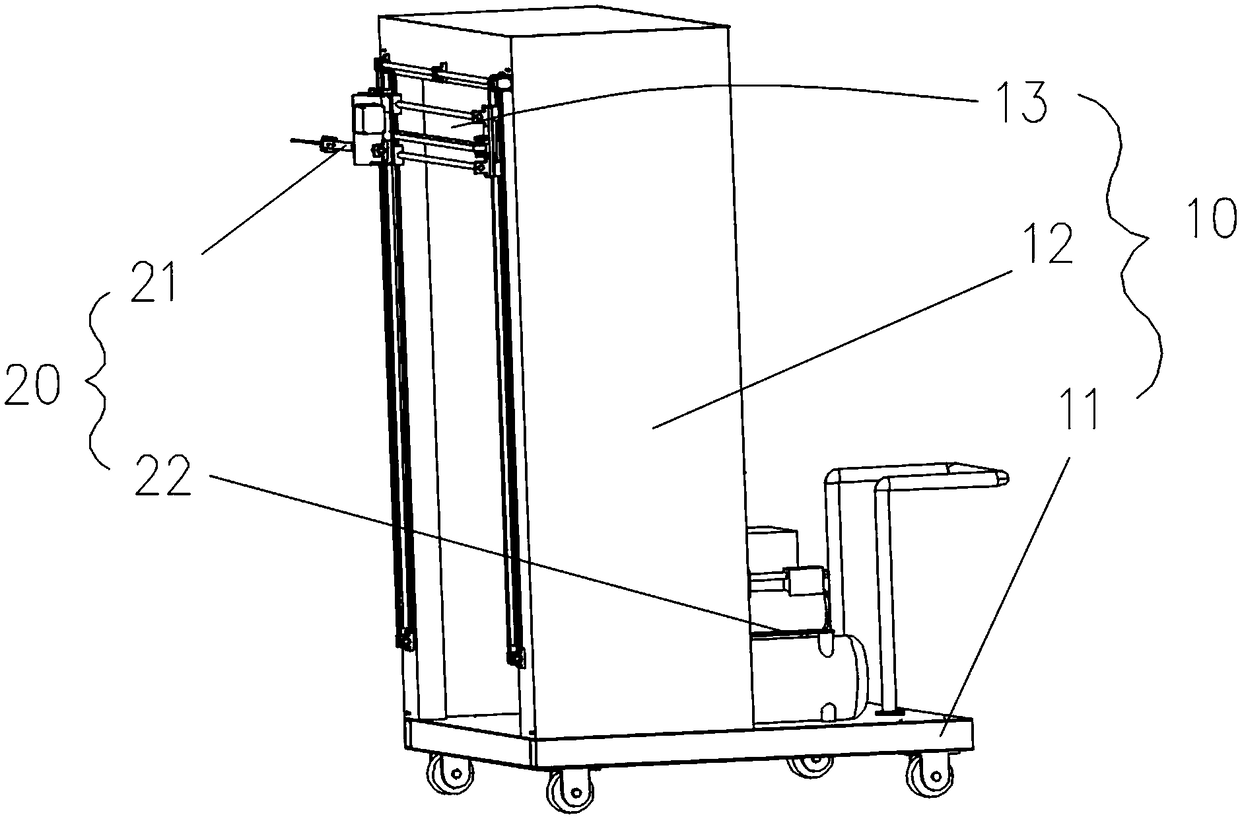

[0037] combine figure 1 , the present embodiment provides an automatic cleaning equipment for a passenger car engine compartment, including a cleaning platform 10 and a cleaning device 20 . The cleaning platform 10 includes a carrier board 11 , a gantry frame 12 mounted on the carrier board 11 , and a moving mechanism 13 erected on the end surface of the gantry frame 12 . The cleaning device 20 includes a swing member 21 and a dry ice blaster 22 placed on the carrier plate 11 .

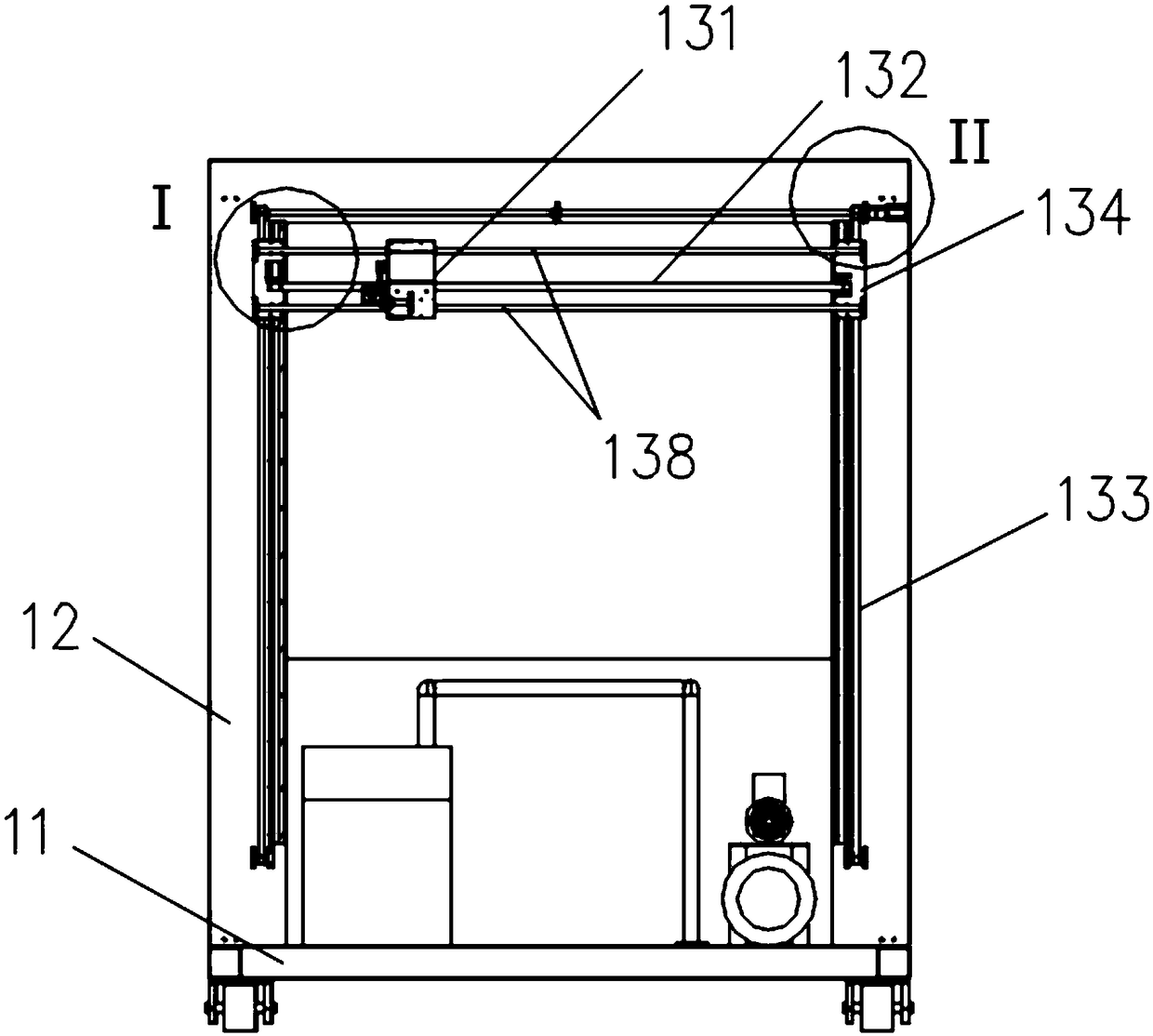

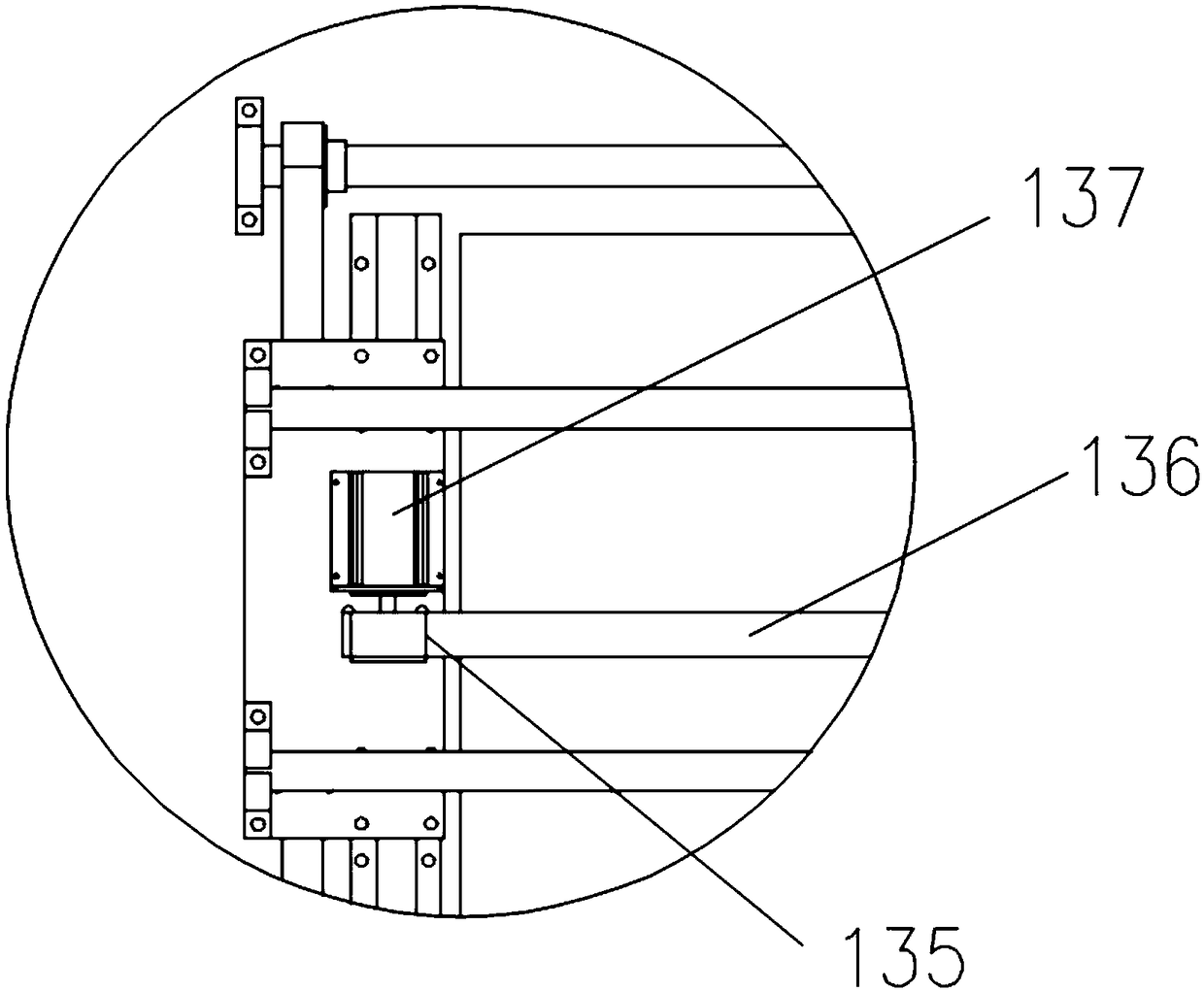

[0038] refer to Figure 2-4It can be seen that the moving mechanism 13 has a moving seat 131 that can move along the X-axis and Z-axis directions perpendicular to each other, including a first sliding rail 132 arranged along the X-axis direction and two second sliding rails 133 arranged along the Z-axis direction. The moving seat 131 is slidably connected to the first slide rail 132, and the two ends of the first slide rail 132 are slidably connected to the second slide rail 133 through two slide se...

Embodiment 2

[0052] see Figure 9-11 , a kind of automatic cleaning equipment for passenger car power cabin provided by Embodiment 2 of the present invention, its realization principle is roughly the same as that of Embodiment 1, please refer to the content in Embodiment 1 for the details not mentioned in this implementation.

[0053] The automatic cleaning equipment for the passenger car power cabin of the present embodiment also includes a dust cover 30 and a vacuum cleaner 40 placed on the carrier plate 11. One side of the dust cover 30 is fixedly connected to the gantry frame 12, and the other side can be connected to the passenger car. The power compartment is connected to close the gap between the passenger car power compartment and the gantry frame 12. The dust cover 30 is an organ type dust cover 31, and the organ type dust cover 31 includes a cover body 32, a guide rod 33, and a spring 34 passing through the guide rod 33, and one end surface of the cover body 32 is fixed on the O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com