Unmanned garbage treatment ship

A garbage disposal and garbage disposal device technology, applied in the field of unmanned garbage disposal ships, can solve problems such as low salvage efficiency, increased hull fuel volume, waste of manpower and material resources, etc., to solve manual salvage and transportation, improve efficiency and quality, The effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

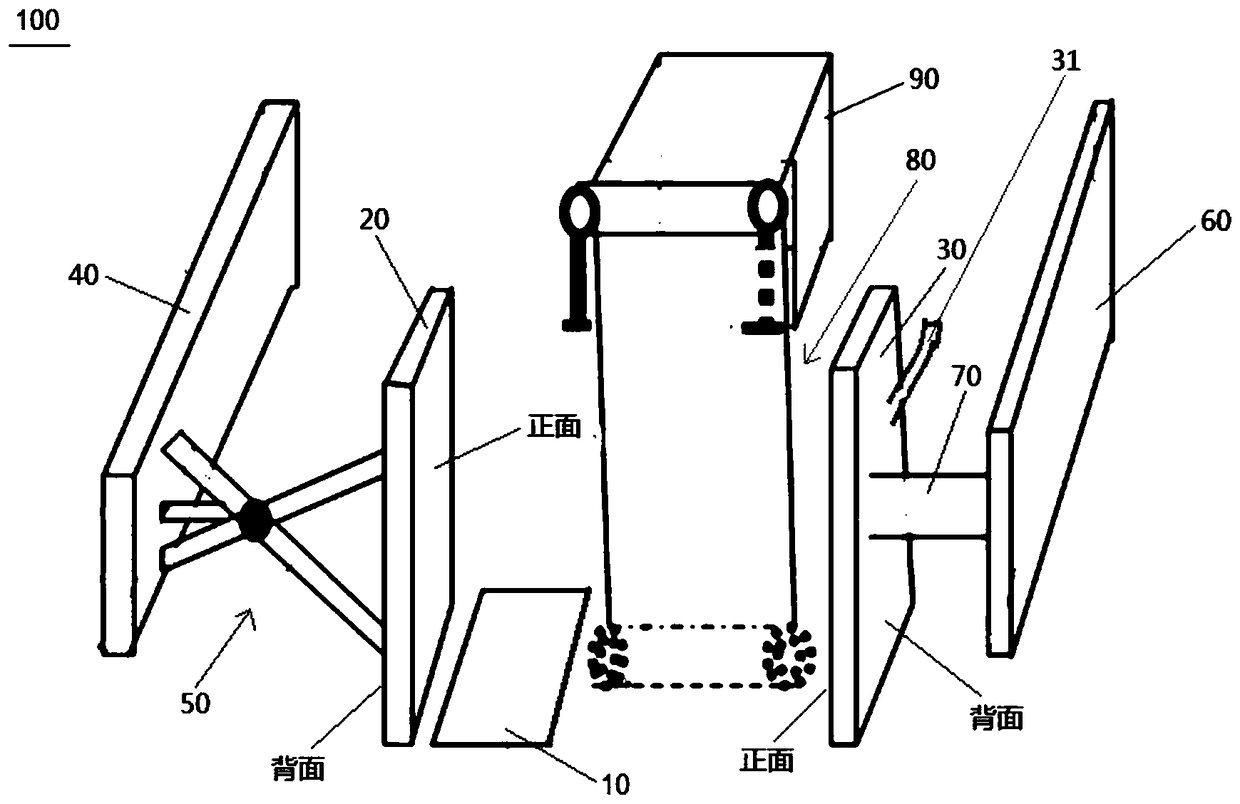

[0029] Example: see figure 1 , an unmanned garbage disposal ship, equipped with a garbage disposal device 100, by installing the garbage disposal device 100, the garbage salvaged from the water surface can be compressed and processed, the water in the surface garbage can be effectively discharged, and the weight of the hull can be reduced, which effectively solves the problem of The difficulty of manual salvage and transportation of water surface garbage can reduce the cost of salvage and transportation.

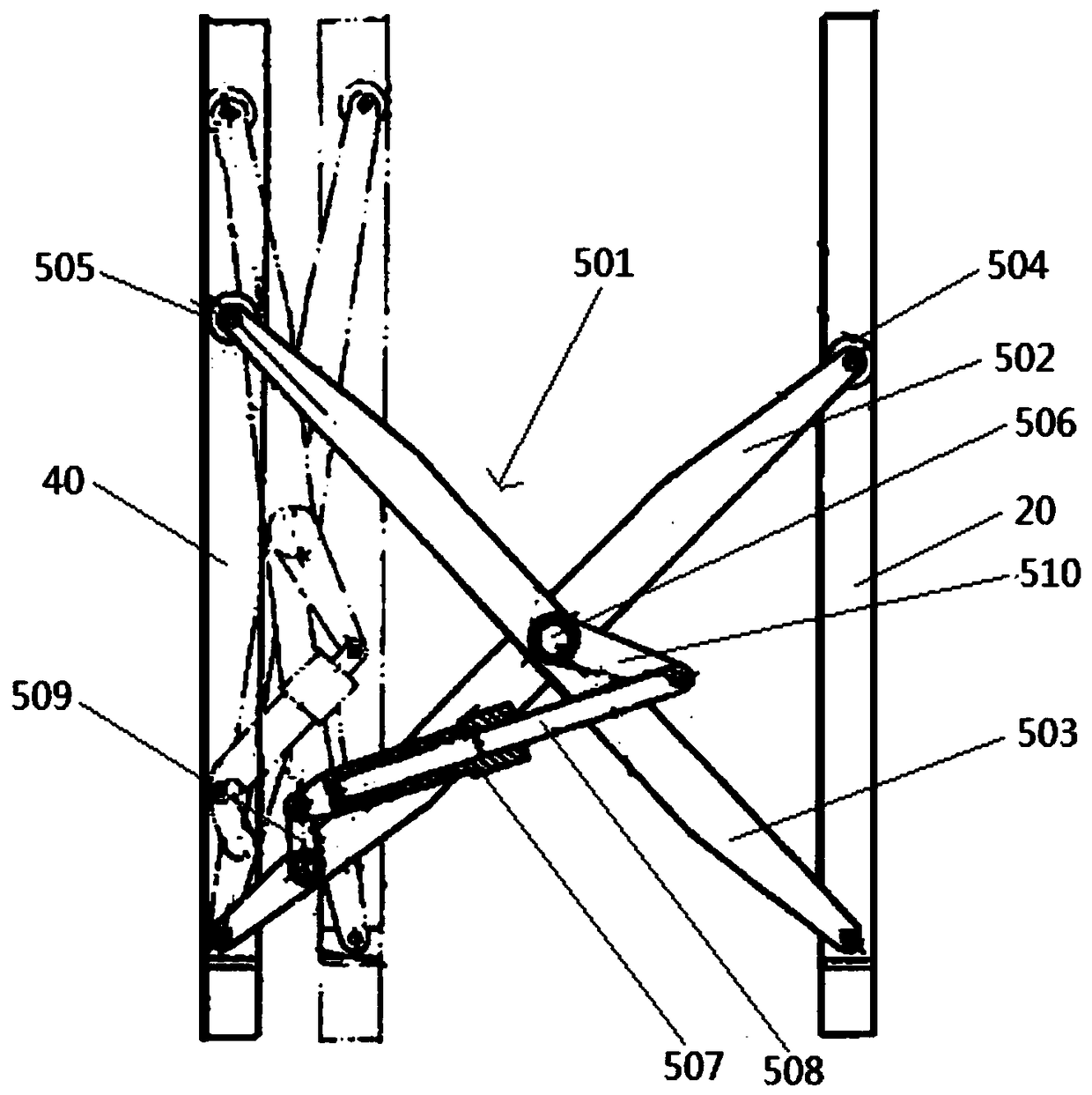

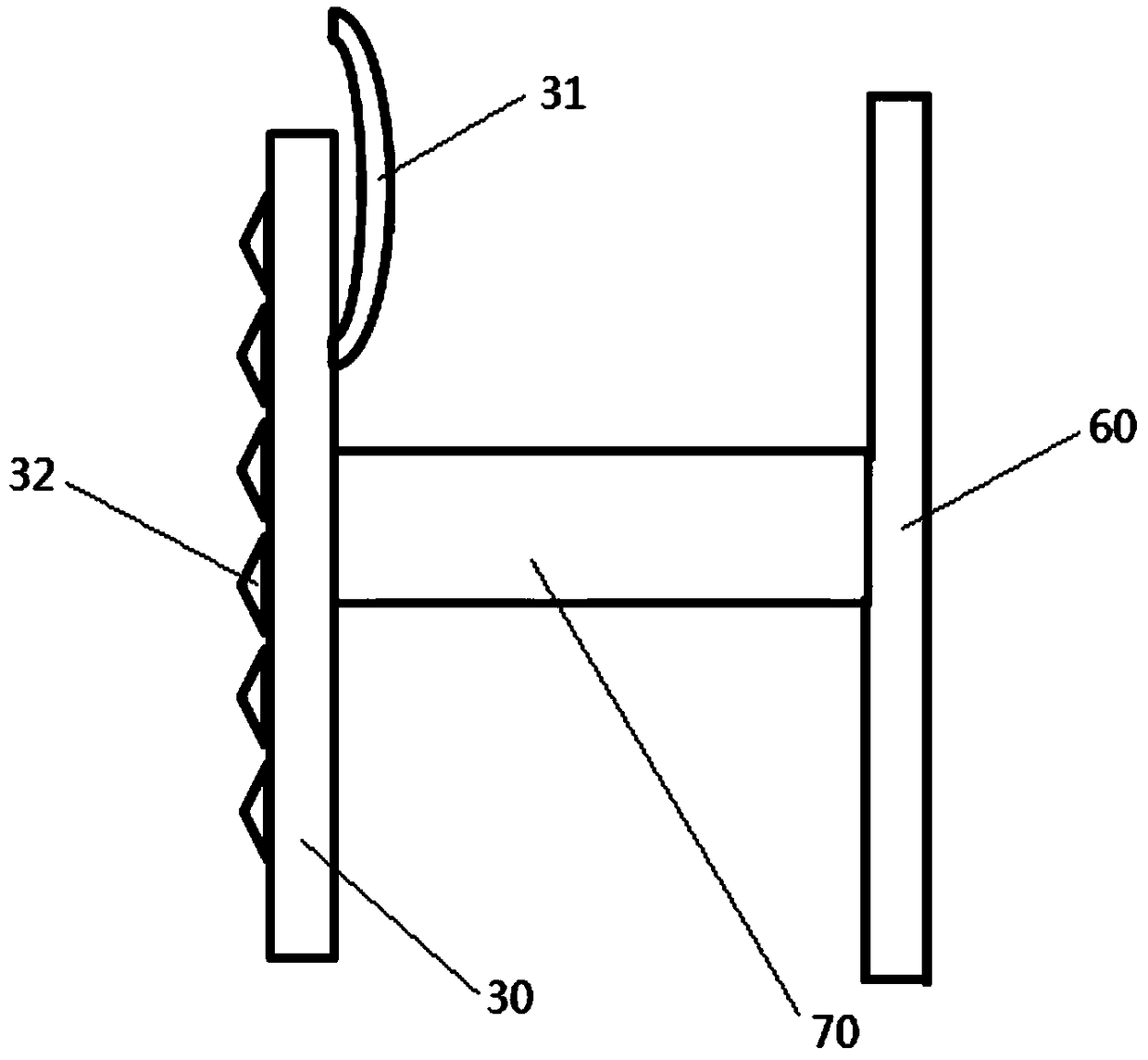

[0030] The garbage disposal device 100 includes a weighing platform 10 for weighing wet garbage floating on the water surface carried by the conveyor belt, and a load cell (not shown) is installed on the lower surface of the weighing platform 10 to weigh The left side of the platform 10 is provided with a first compression panel 20, the right side of the weighing platform 10 is provided with a second compression panel 30, the first compression panel 20 and the second compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com