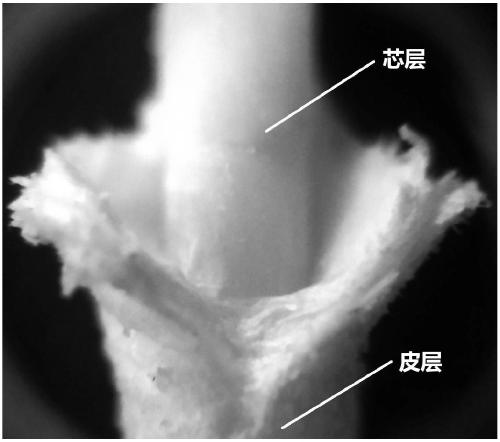

Preparation method for 3D printed wire rod with functionalized skin-core structure

A skin-core structure and 3D printing technology, which is applied in the direction of additive processing, can solve problems such as waste, and achieve the effects of improving service life, reducing environmental pollution, and reducing the amount of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A 3D printing wire with a functional skin-core structure consists of 45 parts of OBC, 50 parts of PLA, and coupling agent coated TiO 2 Makes up 5 servings.

[0023] The preparation method is to carry out according to the following steps:

[0024] (1) 500 g TiO 2 Add 5g of vinyltriethoxysilane coupling agent (WD-20) into the high mixer, keep the rotation speed at 2000 rpm, stir at high speed for 30 min, and the coupling agent coats TiO 2 ;

[0025] (2) Coating 0.5 kg of coupling agent on TiO 2 , 4.5 kg of OBC mixed and then added to the twin-screw extruder for melt blending. The parameters of the twin-screw extruder are: 80°C in the first zone, 90°C in the second zone, 100°C in the third zone, 110°C in the fourth zone, and 110°C in the fifth zone 120°C, 130°C in the sixth zone, 130°C in the seventh zone, 120°C in the eighth zone, 110°C in the ninth zone, 100°C at the die head, and a rotation speed of 200 rpm. Extrude and granulate to obtain TiO 2 / OBC masterbatch; ...

Embodiment 2

[0028] A 3D printing wire with a functional skin-core structure consists of 45 parts of OBC, 50 parts of PLA, and 5 parts of graphene coated with a coupling agent.

[0029] The preparation method is to carry out according to the following steps:

[0030] (1) Add 500 g graphene and 6 g vinyltriethoxysilane (A151) into the high mixer, keep the speed at 2000 rpm, stir at high speed for 30 min, and coat the graphene with the coupling agent;

[0031] (2) Mix 0.5 kg of coupling agent-coated graphene and 4.5 kg of OBC and add them into a twin-screw extruder for melt blending. The parameters of the twin-screw extruder are: 80°C in the first zone and 90°C in the second zone , the third zone is 100°C, the fourth zone is 110°C, the fifth zone is 120°C, the sixth zone is 130°C, the seventh zone is 130°C, the eighth zone is 120°C, the ninth zone is 110°C, the die head is 100°C, the rotation speed is 200 rpm, extruding pellets , to obtain graphene / OBC masterbatch;

[0032] (3) Mix 5.0 kg ...

Embodiment 3

[0034] A 3D printing wire with a functional skin-core structure consists of 30 parts of POE, 65 parts of PLA, and 5 parts of carbon black coated with a coupling agent.

[0035] The preparation method is to carry out according to the following steps:

[0036] (1) Add 500g of carbon black and 4g of vinyltrimethoxysilane (A171) into the high mixer, keep the speed at 2000rpm, stir at high speed for 30min, and coat the carbon black with the coupling agent;

[0037] (2) Mix 0.5 kg of coupling agent-coated carbon black and 3.0 kg of POE and add them into a twin-screw extruder for melt blending. The parameters of the twin-screw extruder are: 75°C in the first zone and 85°C in the second zone , the third zone is 95°C, the fourth zone is 100°C, the fifth zone is 115°C, the sixth zone is 125°C, the seventh zone is 125°C, the eighth zone is 115°C, the ninth zone is 105°C, the die head is 100°C, the rotation speed is 180 rpm, extruding pellets , to obtain carbon black / POE masterbatch;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com