Non-curing rubber asphalt waterproof coating and preparing method thereof

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the direction of asphalt coatings and coatings, which can solve the problems of expensive raw materials, difficulty in achieving full viscosity, hidden safety hazards of modifiers, etc., to solve compatibility problems, The effect of improving waterproof reliability and solving the problem of water channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

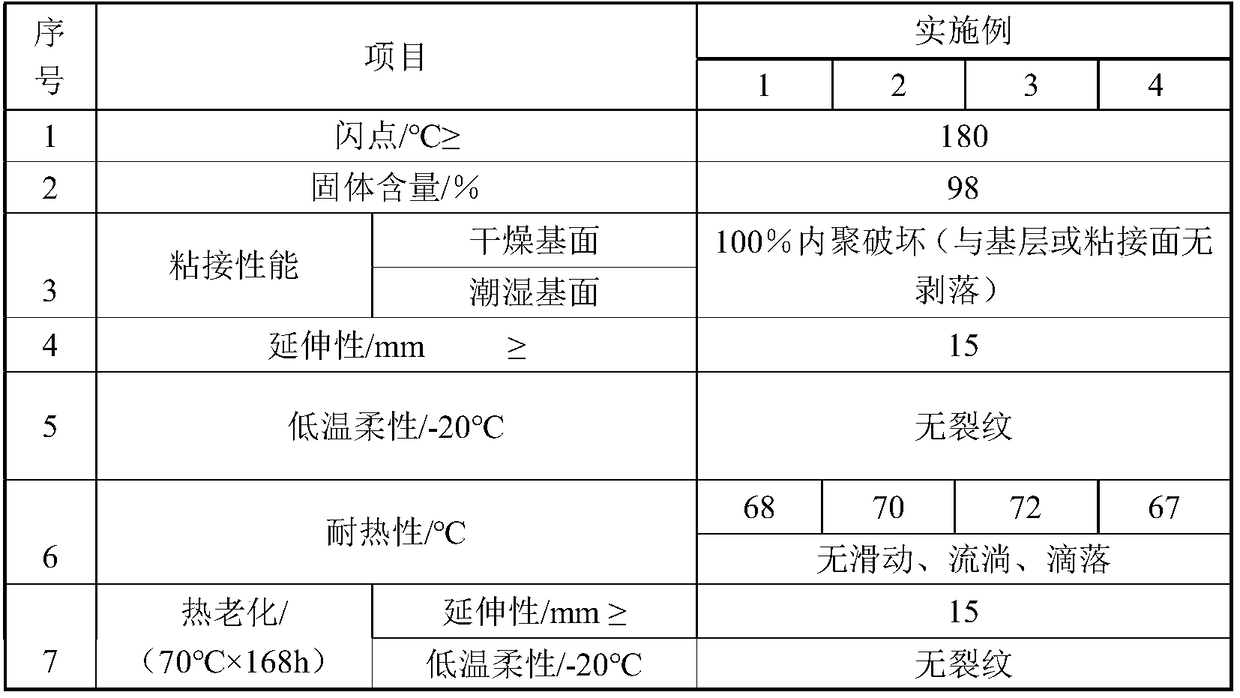

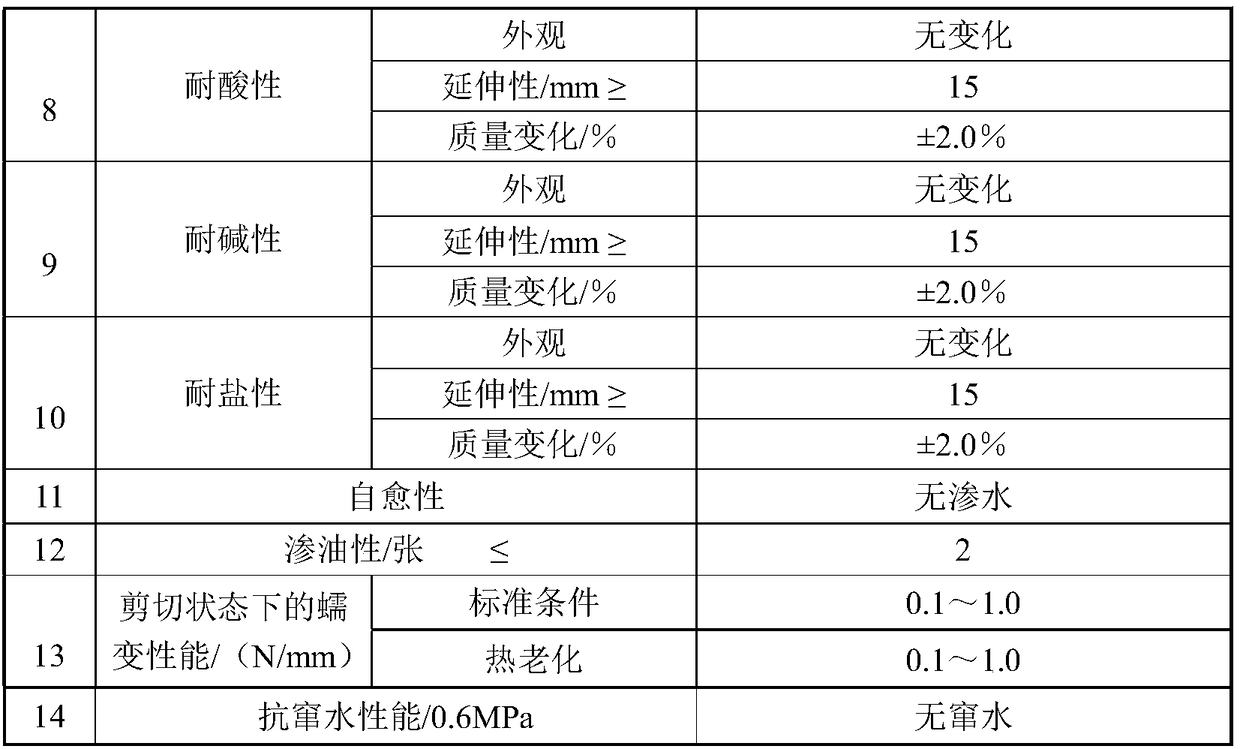

Examples

Embodiment 1

[0030] Prepare each raw material according to the following formula, in parts by weight: 44 parts of 90# asphalt, 15 parts of naphthenic oil, 2 parts of modifier A (modified polypropylene wax H430), modifier B (linear phenylacetic acid-isoamyl Diene-styrene thermoplastic block copolymer S1105) 3 parts, modifier C (linear polyisobutylene 680) 3 parts, rosin resin 2 parts, SBR 5 parts, heavy calcium 10 parts, antioxidant (1010) 1 part , 2 parts of thickener (attapulgite);

[0031] Add asphalt and naphthenic oil into the reaction kettle, heat and keep the temperature to 160°C to form the first product; add modifier B to the first product, stir at high speed for 0.5 hours, stop stirring for 15 minutes, and then continue stirring for 0.5 hours, the second product was formed; the second product was cooled to 140° C., SBR was added, and stirred at a constant temperature and high speed for 2 hours to obtain the third product; modifier A, modifier C, Rosin resin and antioxidant were s...

Embodiment 2

[0033] Prepare each raw material according to the following formula, in parts by weight: 50 parts of 90# asphalt, 16 parts of naphthenic oil, 3 parts of modifier A (modified polypropylene wax H430), modifier B (linear phenylacetic acid-isoamyl Diene-styrene thermoplastic block copolymer S1105) 3 parts, modifier C (linear polyisobutylene 680 and 950 mixed at a mass ratio of 1:2) 5 parts, rosin resin 2 parts, SBR 6 parts, heavy calcium 12 parts , 1.5 parts of antioxidant (1010), 2 parts of thickener (attapulgite);

[0034] Add asphalt and naphthenic oil into the reaction kettle, heat and keep the temperature to 165°C to form the first product; add modifier B to the first product, stir at high speed for 0.5 hours, stop stirring for 15 minutes, and then continue stirring for 0.5 After 1 hour, the second product was formed; the second product was cooled to 145° C., SBR was added, and stirred at a constant temperature and high speed for 2 hours to obtain the third product; modifier ...

Embodiment 3

[0036] Prepare each raw material according to the following formula, in parts by weight: 48 parts of 90# asphalt, 18 parts of naphthenic oil, 4 parts of modifier A (modified polypropylene wax H430), modifier B (linear phenylacetic acid-isoamyl Diene-styrene thermoplastic block copolymer S1105) 4 parts, modifier C (linear polyisobutylene 680 and 950 mixed at a mass ratio of 1:1) 4 parts, rosin resin 2 parts, SBR 5 parts, heavy calcium 12 parts , 1.5 parts of antioxidant (1010), 2 parts of thickener (attapulgite);

[0037] Add asphalt and naphthenic oil into the reaction kettle, heat and keep the temperature to 170°C to form the first product; add modifier B to the first product, stir at high speed for 0.5 hours, stop stirring for 15 minutes, and then continue stirring for 0.5 After 1 hour, the second product was formed; the second product was cooled to 150° C., SBR was added, and stirred at a constant temperature and high speed for 2 hours to obtain the third product; modifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com