Vertical oil-free screw vacuum pump with overpressure exhaust function

A screw vacuum pump and screw technology, applied in the direction of rotary piston pumps, components of pumping devices for elastic fluids, rotary piston type/swing piston type pump components, etc., can solve the adverse effects of on-site workers, pumping air Problems such as prolonged time and reduced pumping efficiency can achieve the effects of eliminating unbalanced factors, improving energy saving effects, and reducing exhaust power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

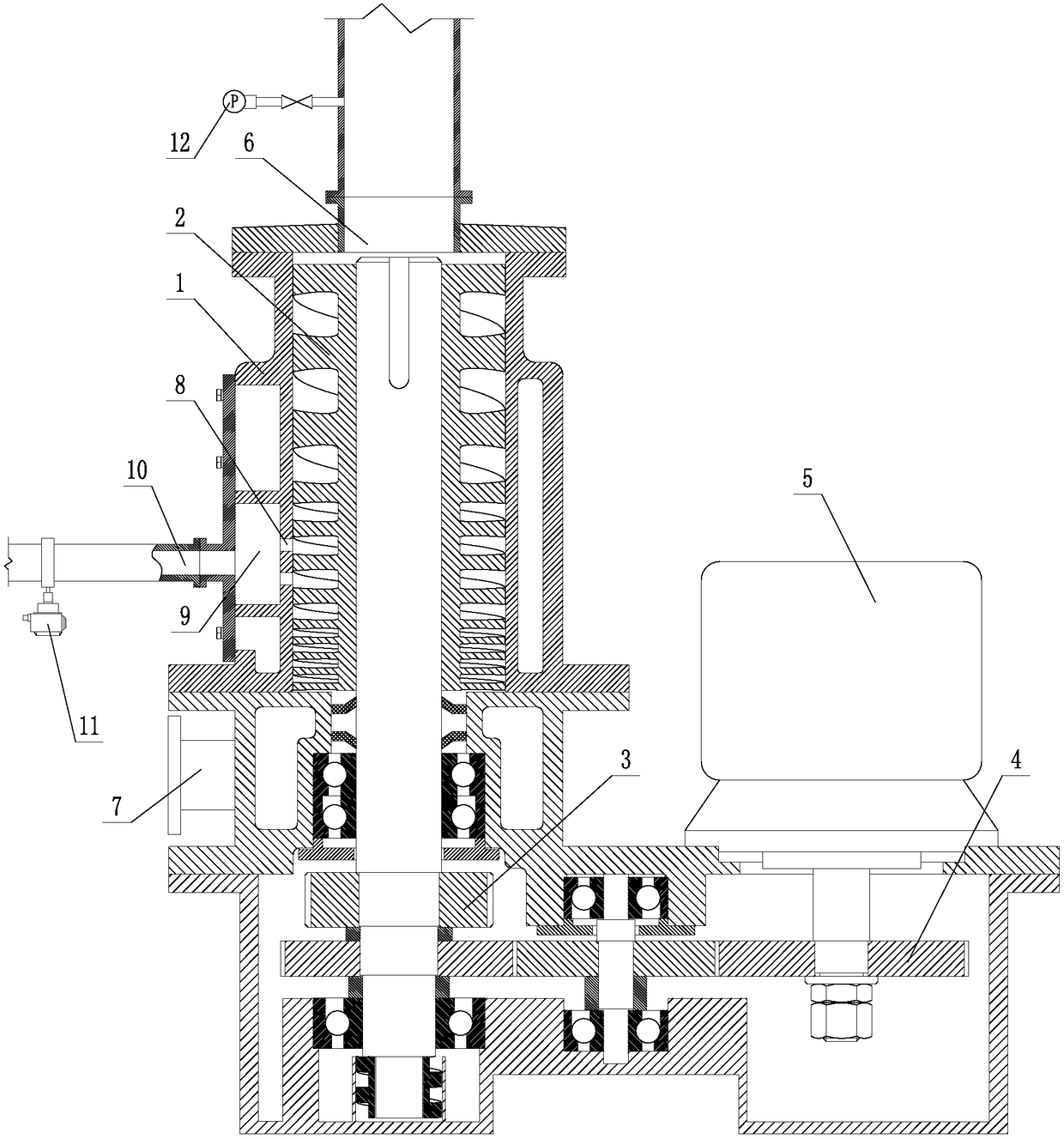

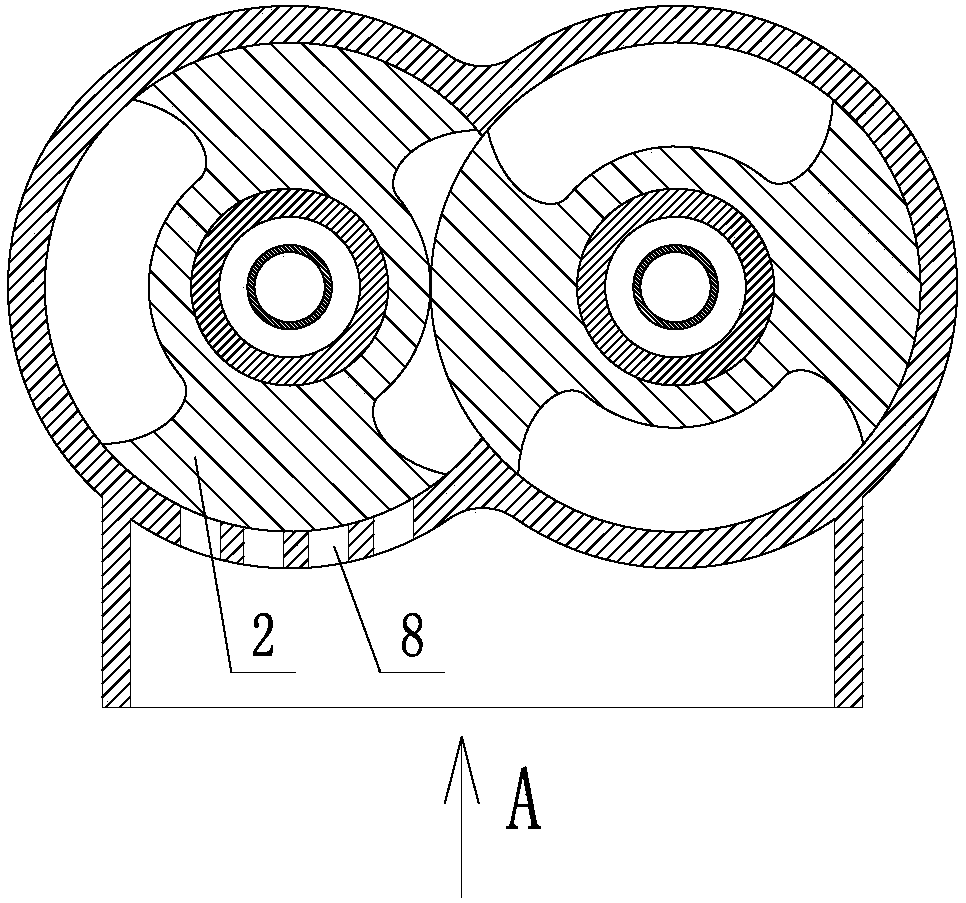

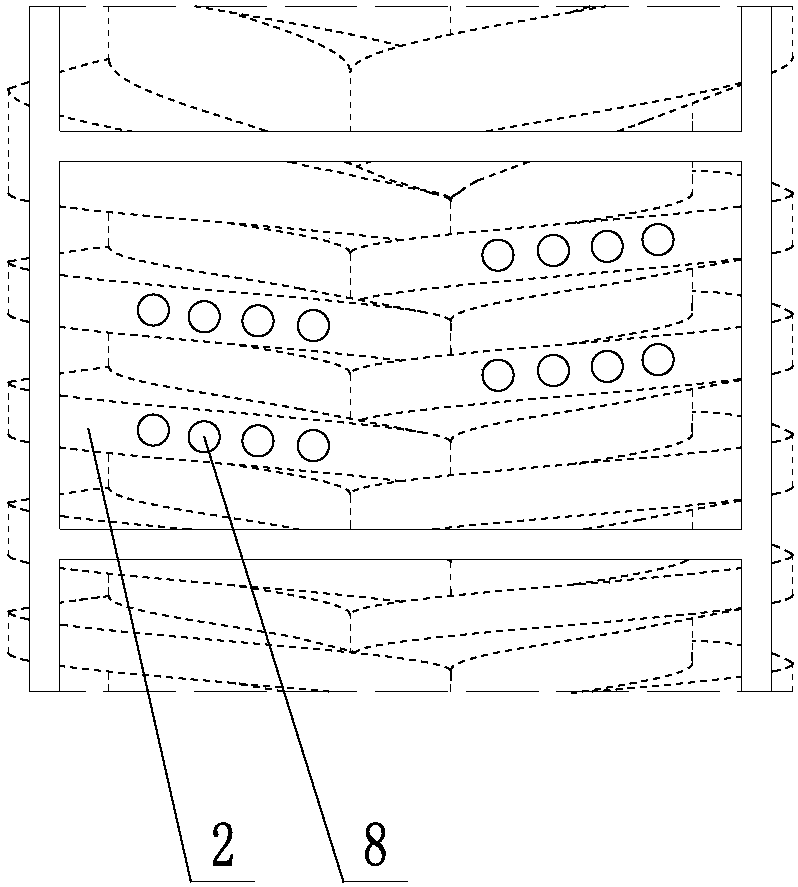

[0047] Such as Figure 1~5 As shown, in this embodiment, the screw rotor 2 is a three-stage variable-pitch screw with equal cross-section, and the screw lead of the screw rotor 2 gradually decreases in three stages along the axis direction from the suction port 6 to the exhaust port 7 of the pump body 1. , and the suction section, compression section and exhaust section of the screw rotor 2 are equal-pitch sections with successively smaller screw leads, the compression ratio R of the screw vacuum pump is set to 4, and the opening position of the pressure relief hole 8 satisfies V in / V m =2, the shape of the pressure relief hole 8 is a circular hole, and the number of each group of pressure relief holes 8 is 8 (the number of each group of pressure relief holes 8 is 4, and the total number of two groups of pressure relief holes 8 is 16) , the pressure relief valve 11 adopts an automatic control vacuum cut-off valve, specifically a GID electric vacuum butterfly valve, the press...

Embodiment 2

[0050] Such as Figure 6-10 As shown, in this embodiment, the screw rotor 2 is a three-stage variable-pitch screw with equal cross-section, and the screw lead of the screw rotor 2 gradually decreases in three stages along the axis direction from the suction port 6 to the exhaust port 7 of the pump body 1. , and the suction section, compression section and exhaust section of the screw rotor 2 are equal-pitch sections with successively smaller screw leads, the compression ratio R of the screw vacuum pump is set to 6, and the opening position of the pressure relief hole 8 satisfies V m =V in / 6 1 / 2 , the shape of the pressure relief holes 8 is a slit hole, and the number of each group of pressure relief holes 8 is 4 (the number of each group of pressure relief holes 8 is 2, and the total number of two groups of pressure relief holes 8 is 8). The pressure valve 11 adopts a manually controlled vacuum cut-off valve, specifically a GU type manual vacuum ball valve. The pressure rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com