Battery pack charge and discharge detection equipment

A technology for testing equipment and battery packs, applied in battery circuit devices, measuring electricity, current collectors, etc., can solve the problems of good heat dissipation effect, inconvenient installation and handling, narrow maintenance space, etc., to achieve reasonable and clean structure distribution, convenient installation and maintenance, Guaranteed cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

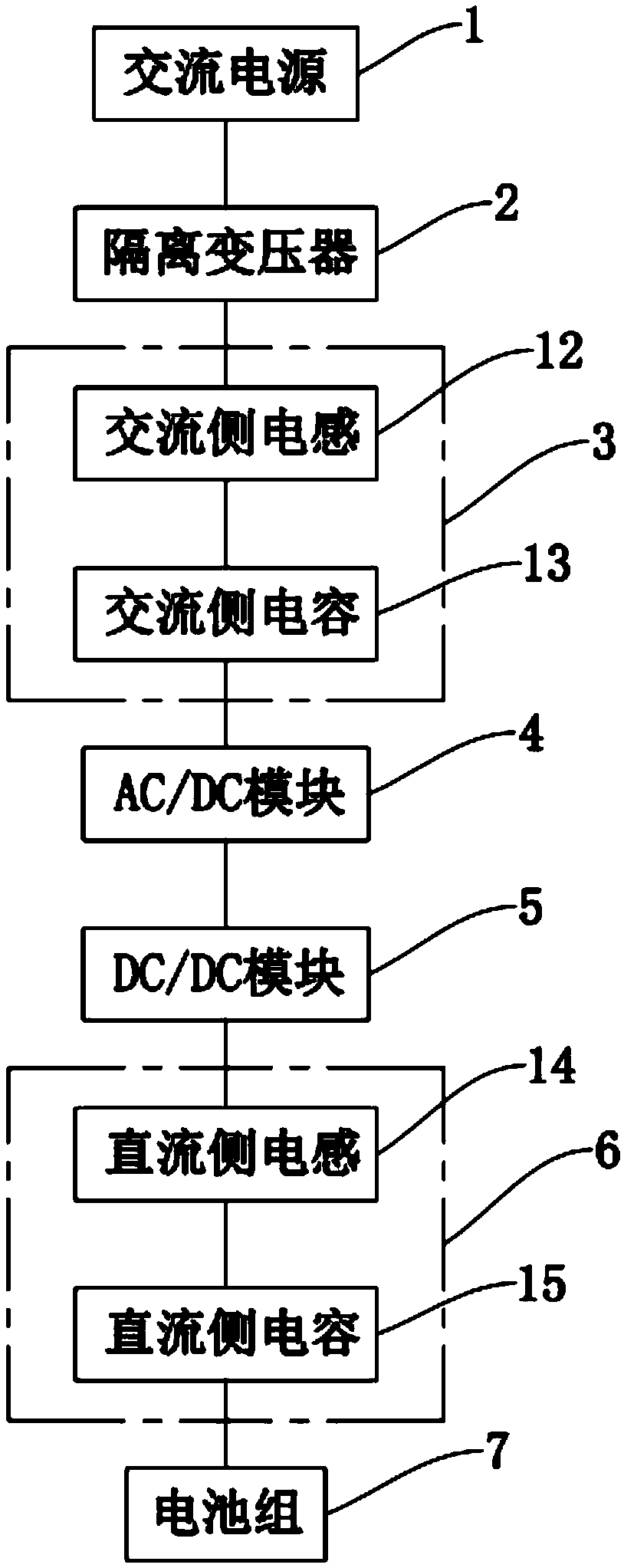

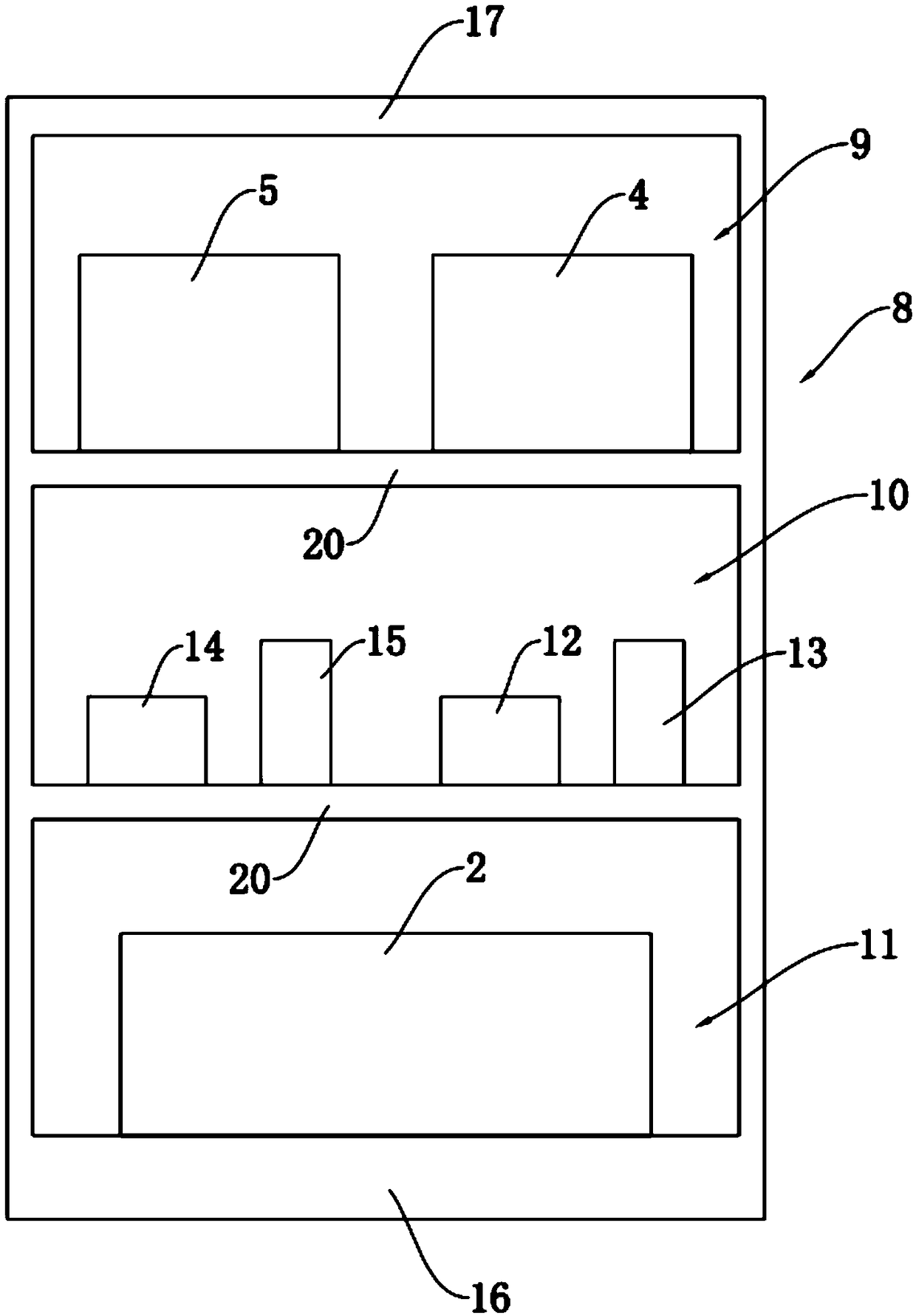

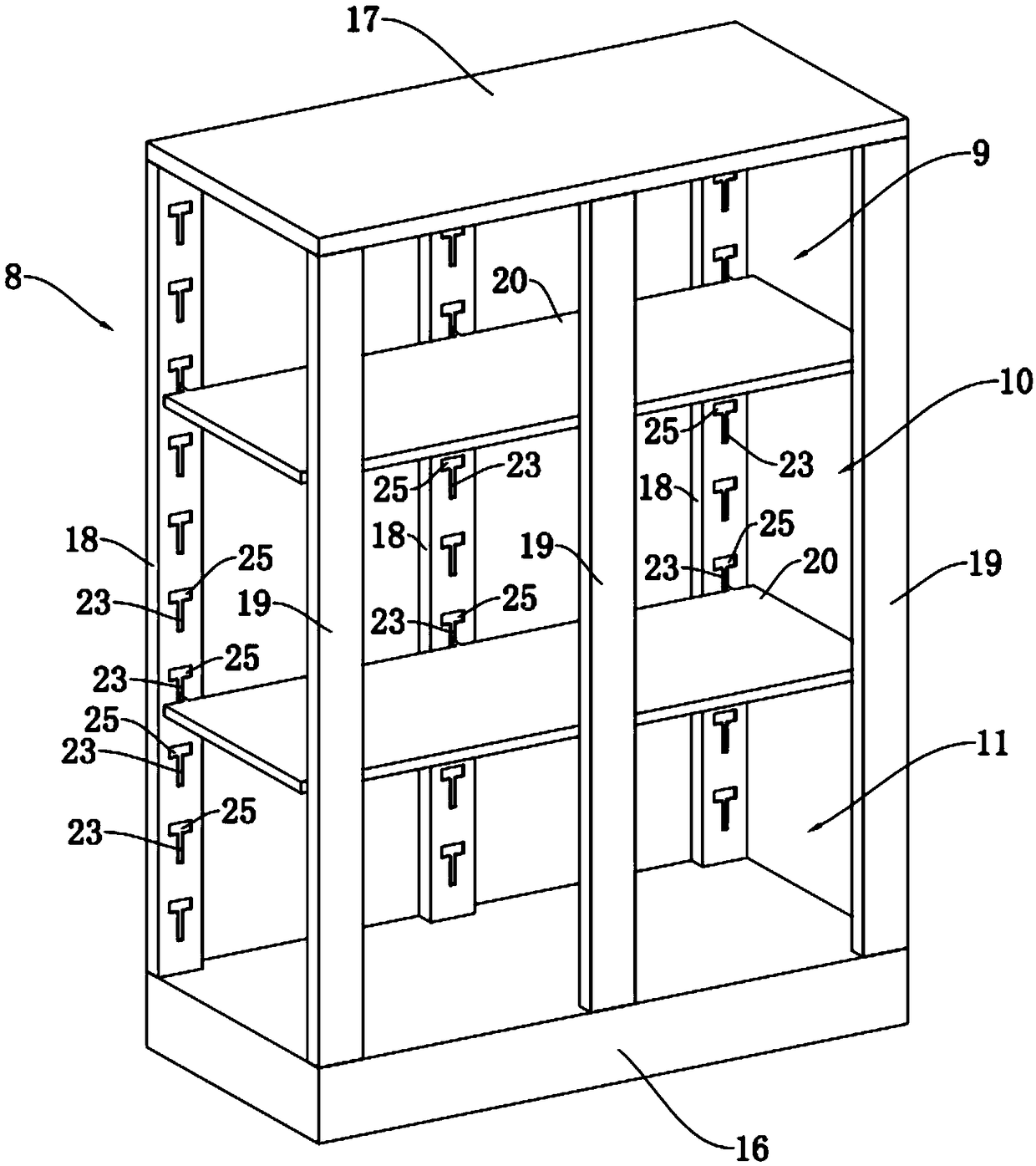

[0024] A battery charge and discharge detection device disclosed in this embodiment, such as figure 1 As shown, it includes an isolation transformer 2 electrically connected to an AC power source 1, an AC side capacitor inductor module 3, an AC / DC module 4, a DC / DC module 5, a DC side capacitor inductor module 6 and a battery pack 7, an isolation transformer 2, The AC-side capacitive-inductive module 3, AC / DC module 4, DC / DC module 5, and DC-side capacitive-inductive module 6 can be connected according to the existing modules. Among them, the type of isolation transformer 2 is the isolation transformer BK series, which can be selected but not limited For the isolation transformer BK185kVA, the model of the AC-side capacitor-inductor module 3 is the AC-side capacitor-inductor module LC series, which can be selected but not limited to the AC-side capacitor-indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com