Vertically-arranged color liquid crystal display

A liquid crystal display, vertical alignment technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of color interference, color mixing deviation, and high cost of mold opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

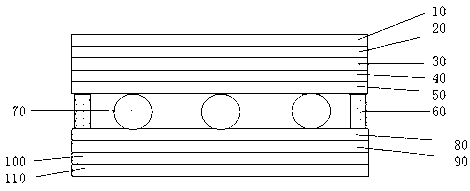

[0020] Example 1: as figure 1 As shown, the LCD structure in the present invention includes an upper polarizer 10, an upper phase difference plate 20, an upper glass substrate 30, an upper ITO layer 40, an upper PI alignment layer 50, a frame glue layer 60, a middle Spacer 70, and a lower PI alignment layer 80, The lower ITO layer 90 , the lower glass substrate 100 , and the lower polarizer 110 . The thickness of the LCD cell is controlled as: 2-2.5um, and the twist angle of the liquid crystal is 90-180 degrees.

[0021] In the present invention, the thickness of the middle Spacer 70 box is designed to be 2-2.5um, and the twist angle of the liquid crystal is 90-180 degrees. The PI material of vertical alignment is selected, and the negative vertical alignment liquid crystal with low viscosity is poured into the liquid crystal box to make it have a fast Responsiveness, by calculating the optical path difference in the optical design, select an optical retardation film of 220-6...

Embodiment 2

[0028] Embodiment 2: On the basis of the foregoing embodiments, as figure 1 As shown, a color vertically aligned liquid crystal display includes a main control board and an LCD body, wherein the LCD body is sequentially composed of an upper polarizer 10, an upper phase difference plate 20, an upper glass substrate 30, an upper ITO conductive glass layer 40, an upper PI alignment film layer 50, frame adhesive layer 60, intermediate space layer 70, lower PI alignment film layer 80, lower ITO conductive glass layer 90, lower glass substrate 100 and lower polarizer 110 plate.

[0029] On the basis of the above-mentioned embodiment, wherein, low-viscosity negative vertical alignment liquid crystal is poured into the liquid crystal cell; the viscosity coefficient of the liquid crystal is 15-25 (mm2·s-1).

[0030] On the basis of the above embodiment, wherein, the thickness of the liquid crystal cell is set to 2-2.5um.

[0031] On the basis of the above embodiment, wherein, the twis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Twist angle | aaaaa | aaaaa |

| Viscosity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com