Preparation method of soft template in lattice structure for ultraviolet nano imprinting

A technology of nanoimprinting and lattice structure, applied in the field of nanoimprinting, which can solve the problems of ineffective transfer of graphics, free entry, high viscosity of PDMS, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following implementations. example.

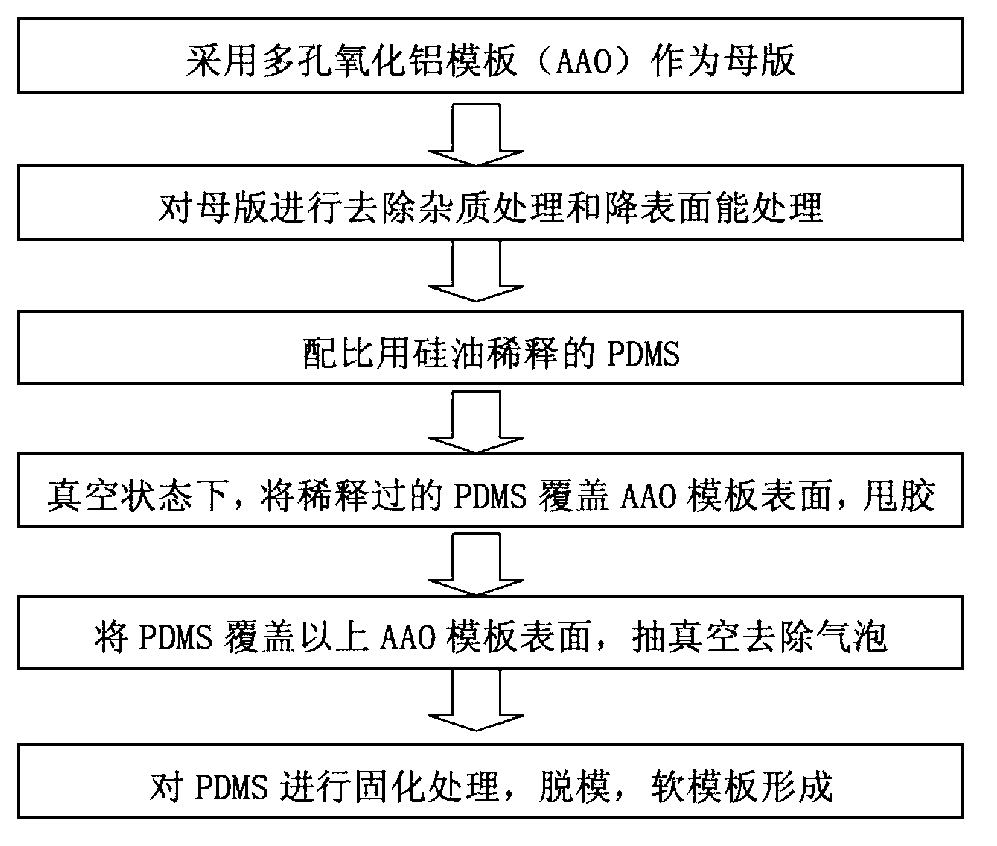

[0023] Such as figure 1 As shown, this embodiment includes the following steps:

[0024] (1) Use porous alumina template (AAO) as the master;

[0025] (2) Impurity removal treatment and surface energy reduction treatment on the master;

[0026] (3) Proportioning PDMS diluted with silicone oil;

[0027] (4) In a vacuum state, cover the diluted PDMS on the surface of the AAO template, and then use a homogenizer to shake off the excess liquid;

[0028] (5) Cover the surface of the above AAO template with undiluted PDMS, and vacuum to remove bubbles;

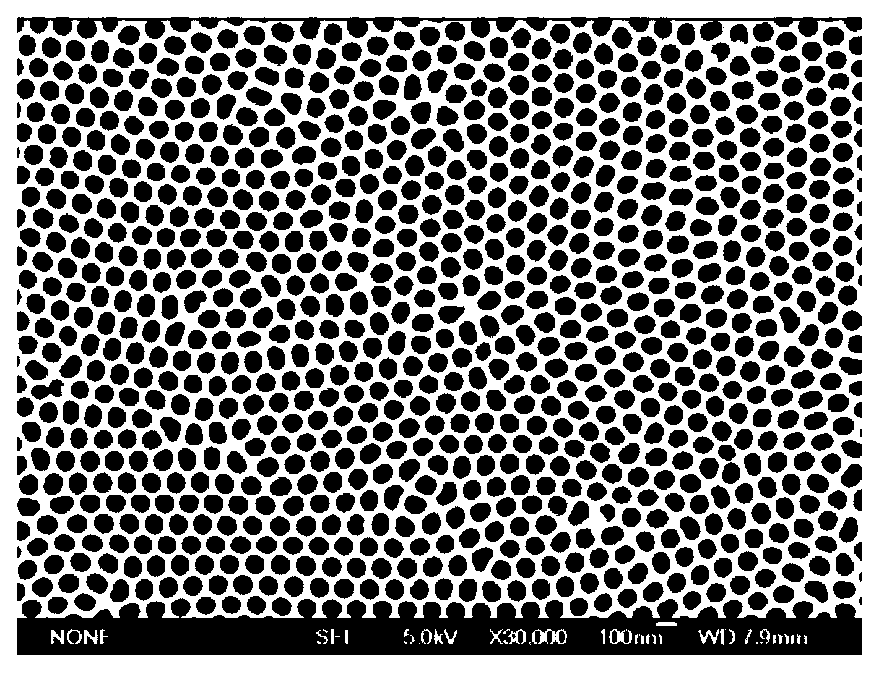

[0029] (6) The PDMS is cured, and after demolding, the nano-level pattern transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com