Motor soft starter based on magneto-rheological grease

A technology of electric motor and soft start, applied in the field of electric motor soft starter and motor power transmission device, can solve the problems of low transmission efficiency, high manufacturing and maintenance cost, and large power loss of liquid viscous soft starter, so as to achieve the goal of manufacturing and maintenance. Low cost, increased damping coefficient control, enhanced stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

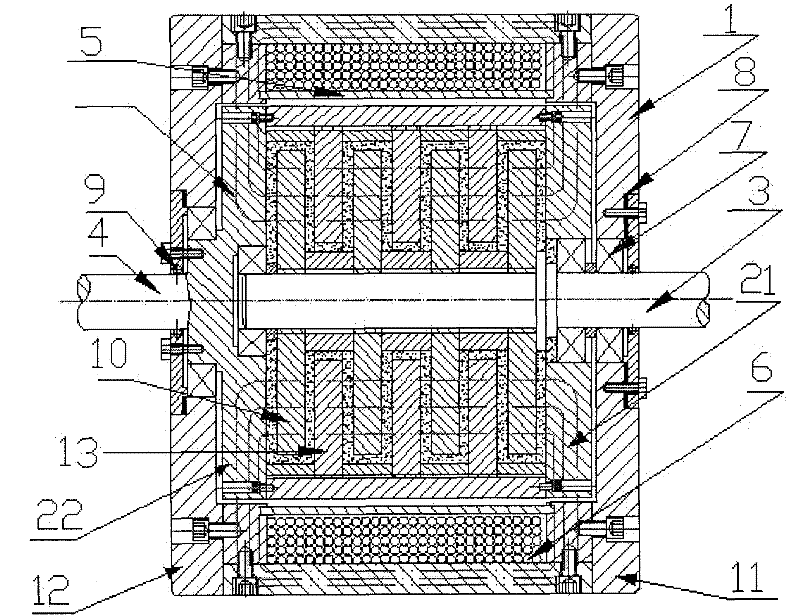

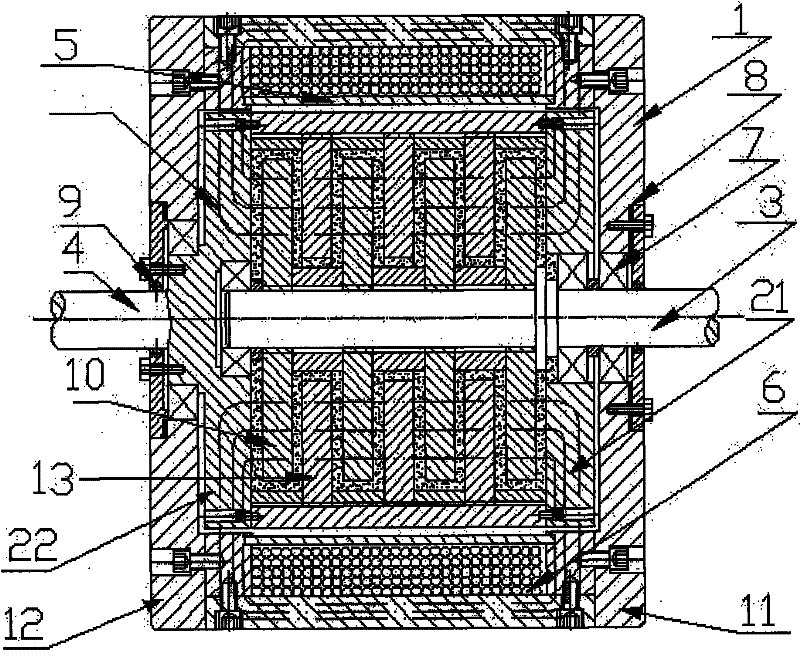

[0023] The present invention will be described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the present invention mainly includes a casing 1, a working cylinder 2, an input torque rotating shaft 3, and an output torque rotating shaft 4, and the magnetorheological grease is enclosed in the working cylinder 2. The casing 1 is a cylindrical hollow sealing body, and the working cylinder 2 is a cylindrical hollow sealing body arranged inside the casing 1 and coaxial with the casing 1 . There is a distance between the outer wall of the working cylinder 2 and the inner wall of the casing 1 . An isolation plate 5 is arranged between the inner side wall of the housing 1 and the outer side wall of the working cylinder 2 , and the excitation coil 6 is wound around the cylindrical cavity between the isolation plate 5 and the inner side wall of the housing 1 . The working cylinder 2 can rotate freely in the cavity formed by the isolation plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com