Numerical simulation of pipeline erosion with paste filling

A paste filling and numerical simulation technology, which is used in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as difficulty in calculating the erosion wear rate of pipes, and difficulty in obtaining the instantaneous velocity of particles in the slurry. , to achieve the effect of extension and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Specific embodiments of the present invention are further described below.

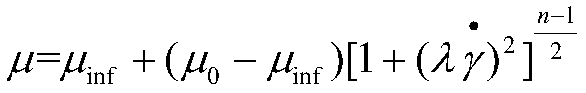

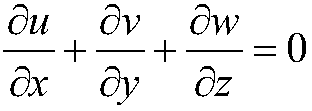

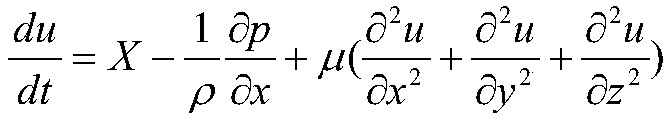

[0072] The invention mainly utilizes indoor physical simulation technology and mathematical method, according to the rheological characteristics of the paste filling slurry, realizes the influence on the flow characteristics of the paste filling slurry pipeline in the numerical simulation of the pipeline, and further realizes the effect on the wear characteristics of the pipeline in the simulation. influences. First, the density of the paste filling slurry is obtained by density measurement; the relationship between shear and fluid viscosity is obtained by fitting the rheological test results; then, the flow mathematical model of the target paste filling slurry is established according to the equation of motion of hydrodynamics, Solve the mathematical model of paste-filling slurry movement, and obtain the velocity and pressure variation law of paste-filling paste in the process of pipeline flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com