High-current carrying capacity multilayer ceramic substrate and manufacturing method thereof

A multi-layer ceramic and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of reduced wiring density and assembly density, affecting system miniaturization, etc., and achieves improvement of current carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

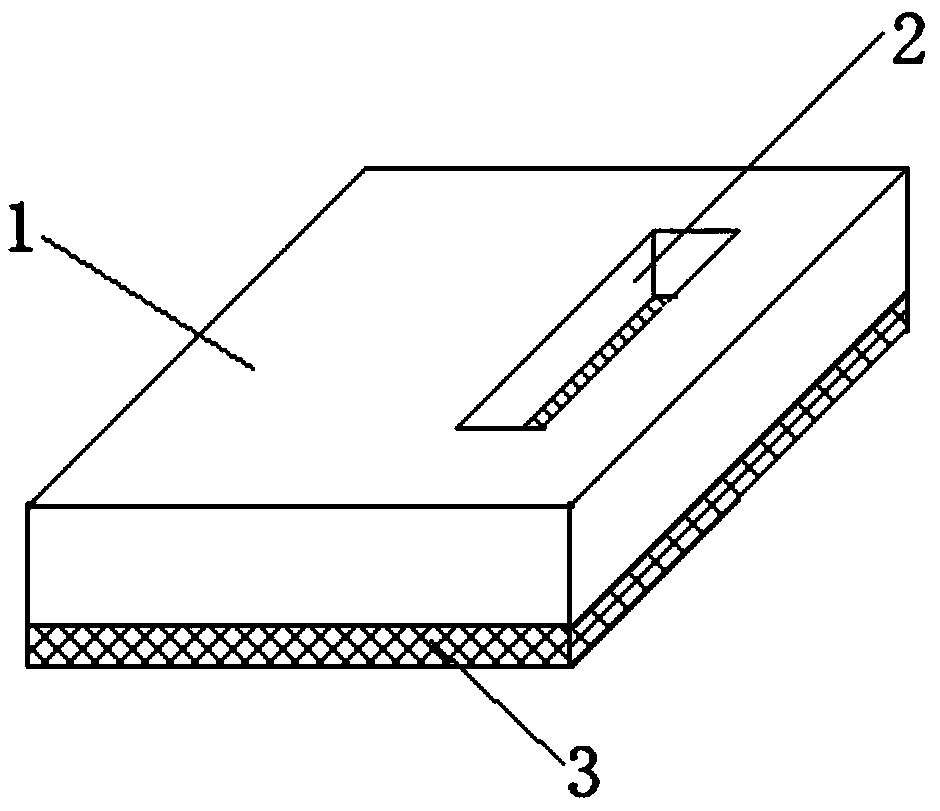

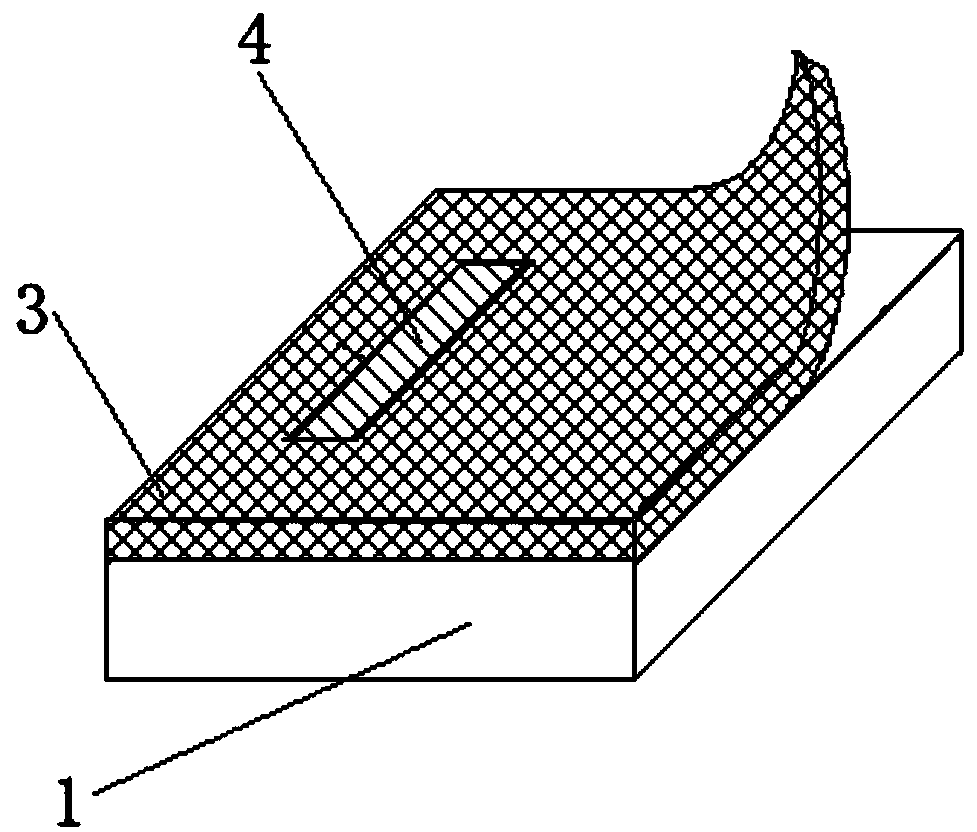

[0043] Embodiment 1: LTCC (low temperature co-fired ceramic) ceramic tape is used to make a substrate of straight wire with high current-carrying capacity. In this embodiment, the wiring length of the straight wire is ≤10 mm. The tape-cast green ceramic sheet 1 is formed by using a square punch with a side length of 0.3mm through one continuous punch figure 2 For the shown continuous through groove 2, in this embodiment, the green ceramic sheet 1 is covered with a back film 3, and the leakage position of the back film 3 is the same as that of the continuous through groove 2, and then the groove is filled with a conductive paste 4, baked After drying, remove the backing film 3 as image 3 As shown, the green ceramic sheet 1 filled with conductive paste 4 is obtained, such as Figure 4 As shown, electrodes and wires are printed on the green ceramic sheet 1. After the conductor is dried, take the three-layer green ceramic sheets L1, L2, and L3 and carry out alignment laminati...

Embodiment 2

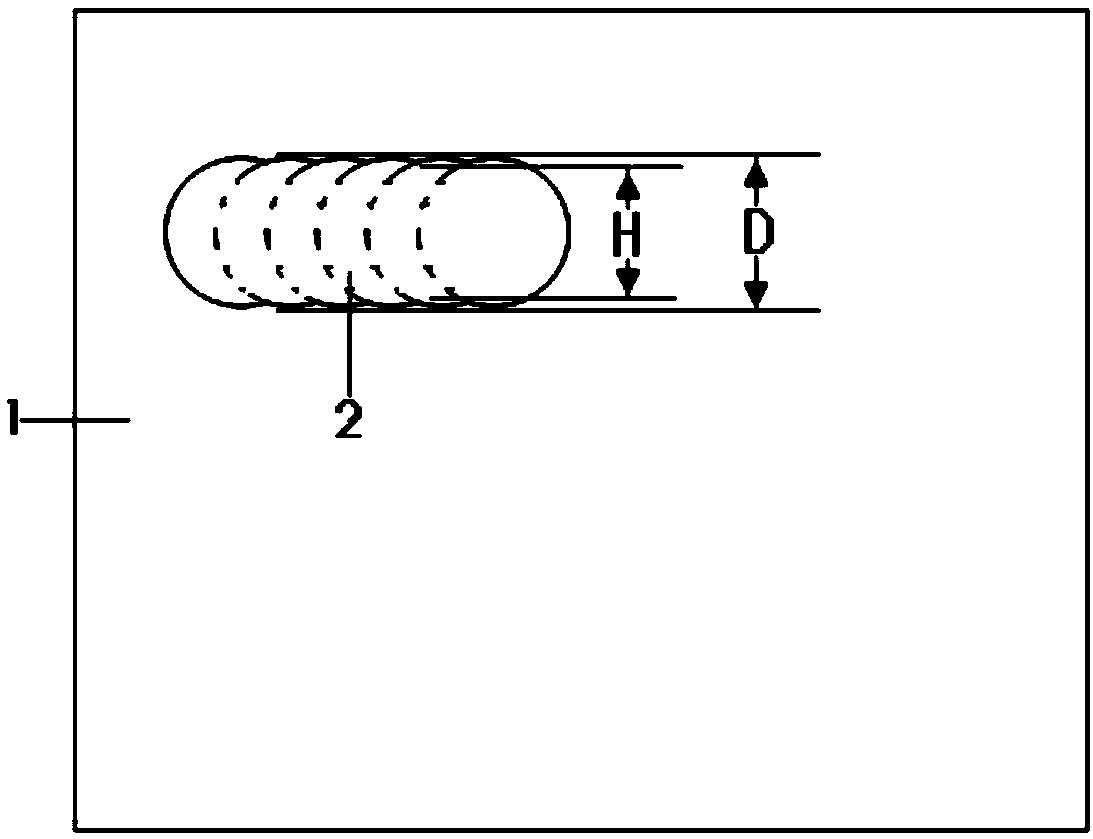

[0044] Embodiment 2: A substrate of a square spiral wire with high current-carrying capacity is manufactured by using LTCC green ceramic tape. The tape-cast green ceramic sheet is punched twice with a circular punch with a diameter of 0.1 mm to form a continuous square spiral through groove. In this embodiment, the stepping distance of the circular punch is selected as circular punch. 1 / 2 of the head diameter (relative to edge flatness H / D = 86.6%). Perform the first segmental punching to form several spaced through grooves on the green ceramic sheet, and fill the grooves with conductive paste, such as Figure 6 As shown, after drying, the second segmental slotting is performed at the interval between adjacent through-slots formed by the first segmental slotting, and then the slots are filled with conductive paste and dried to form an overall continuous square spiral through-slot ,Such as Figure 7 As shown, then print electrodes and wires, etc. After drying, each layer of ...

Embodiment 3

[0045] Embodiment 3: A substrate of a circular spiral wire with high current-carrying capacity is manufactured by using LTCC green ceramic tape. The tape-cast green ceramic sheet is formed with a circular punch with a diameter of 0.4 mm to form a continuous circular spiral through groove through two segmental punches. In this embodiment, the stepping distance of the circular punch is selected as circular. 1 / 4 of the diameter of the punch (relative to the edge flatness H / D=96.8%), perform the first segmental punching to form several spaced through grooves on the green ceramic sheet, fill the grooves with conductive paste, and after drying, Carry out the second segmental punching at the interval between adjacent through-slots formed by the first segmental punching, and then fill the slots with conductive paste and dry to form an overall continuous circular spiral through-slot, such as Figure 8 As shown, then print electrodes and wires, etc. After drying, each layer of green ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com