A deep condensation recovery device for high-concentration organic waste gas

A technology of organic waste gas and deep condensation, applied in steam condensation, gas treatment, separation methods, etc., can solve the problems of carbon bed not being able to dissipate heat in time, low emission concentration, explosion, etc., and achieve improved adsorption treatment effect, low emission concentration, and improved The effect of the factor of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) The discharge outlet of an oil tank at a wharf, with a processing capacity of 500m 3 / h, oil and gas content 125g / m3;

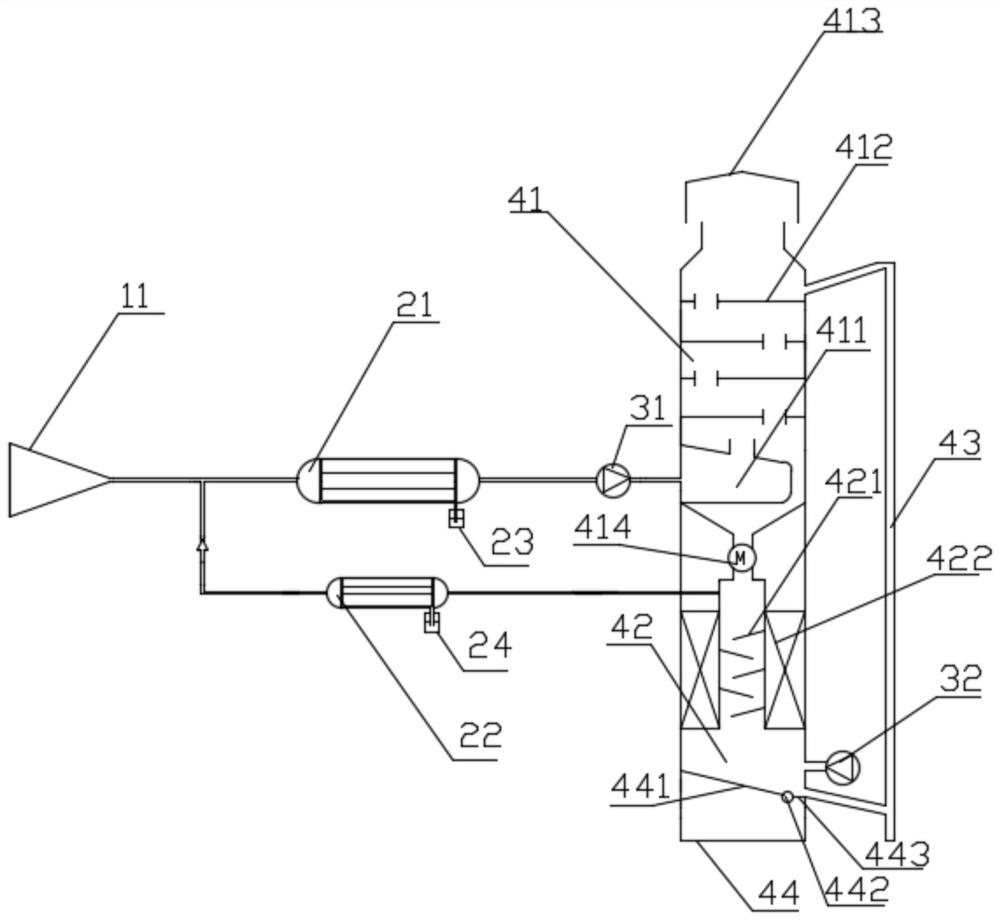

[0052] (2) Five wide-mouth gas collecting hoods are used for collection, with a processing capacity of 500m 3 / h, the deep condenser is designed to condense at -40°C, the normal temperature cooler 22 is set to condense at 20°C, and the oil and gas are condensed to liquid and then recovered. The air flow passes through the bottom fan (520m 3 / h) Quantitative flow to the fluidized adsorption zone 41.

[0053] (3) The fluidized adsorption zone 41 selects a spherical adsorbent as the adsorbent, and the diameter of the adsorbent is less than or equal to 0.6 mm. The four-layer pore sieve plate 412 has a plate thickness of 2 mm. Small holes are evenly opened on the plate, the opening rate is 10%, and the floor height is 300 mm. , arranged in an equilateral triangle, the diameter of the small hole is 2.4mm, there is an overflow cofferdam on the left sid...

Embodiment 2

[0057] (1) The discharge outlet of an oil tank at a gas station, with a processing capacity of 200m 3 / h, oil and gas content 100g / m 3 ;

[0058] (2) Use a wide-mouth gas collecting hood for collection, and the constant air volume of the fan is 90m 3 / h, the deep condenser is designed to condense at -40°C, the normal temperature cooler is set to condense at 20°C, and the oil and gas are condensed to liquid and then recovered. The air flow passes through the bottom fan (210m 3 / h) Quantitative flow to the fluidized adsorption zone 41.

[0059] (3) Spherical adsorbent is selected as the adsorbent in the fluidized adsorption zone 41, the diameter of the adsorbent is ≤0.6mm, the three-layer pore sieve plate 412, the plate thickness is 2mm, small holes are uniformly opened on the plate, the opening rate is 10%, and the layer height is 300mm , arranged in an equilateral triangle, the diameter of the small hole is 2.4mm, there is an overflow cofferdam on the left side, the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com