Small-aperture steel tube 3PE outer anti-corrosion transmission line

A small-diameter, transmission-line technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of unsuitable small-diameter steel pipes, and achieve the effects of improving utilization, simple switching, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

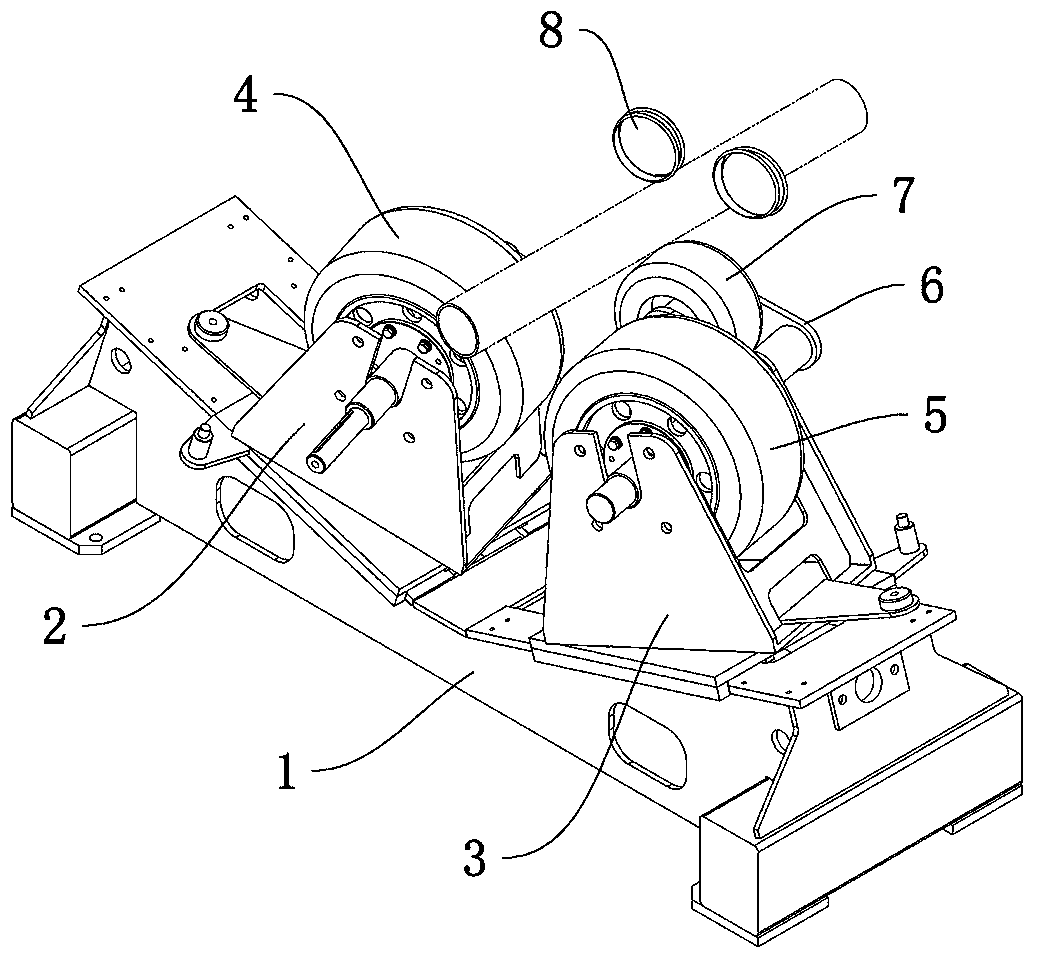

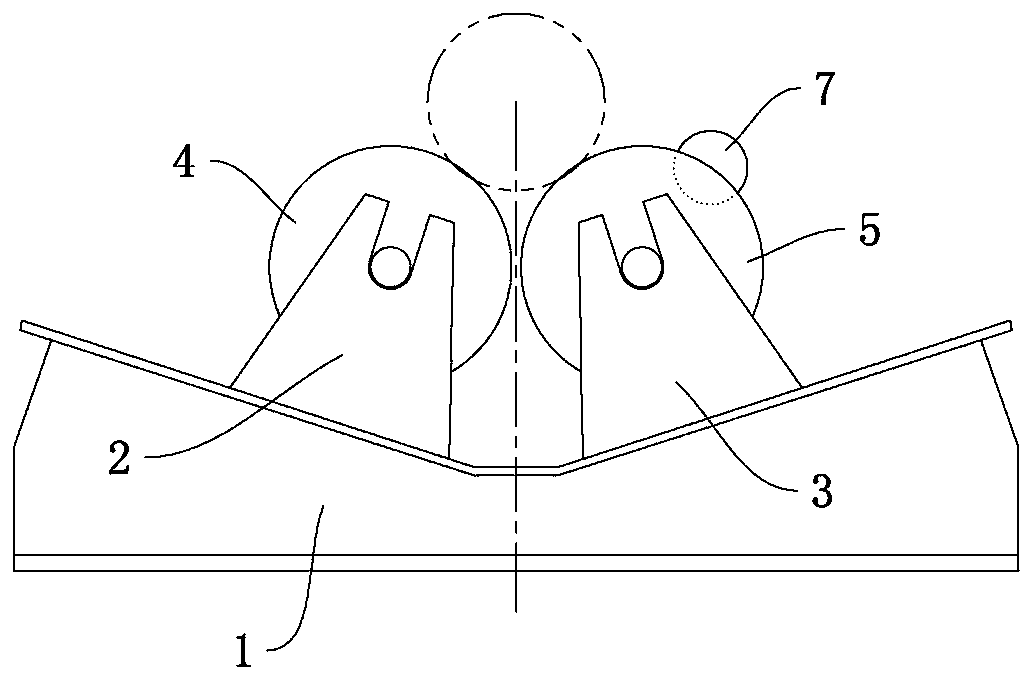

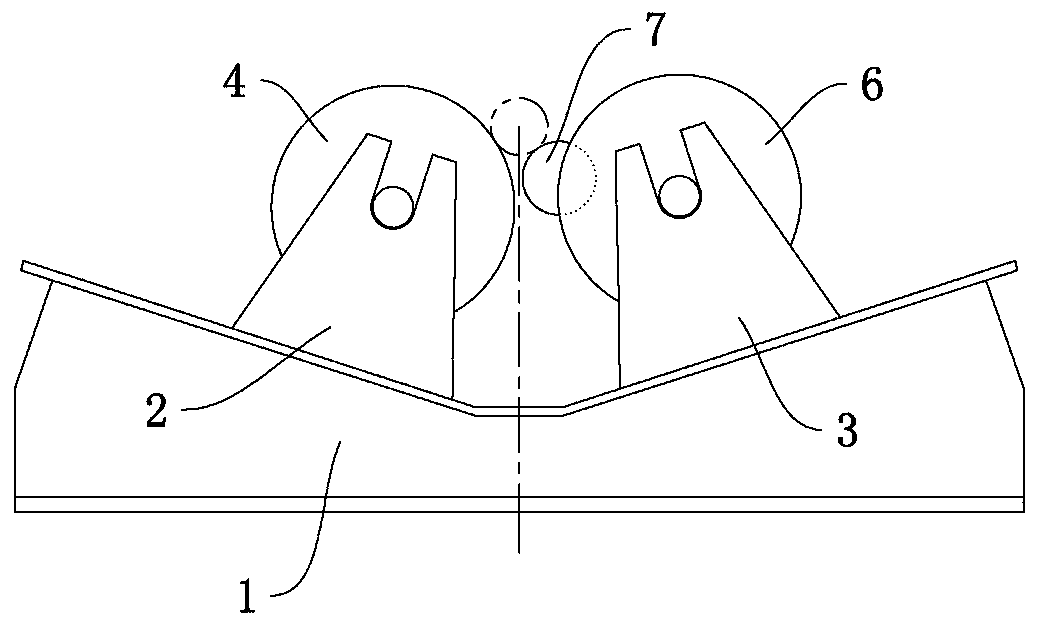

[0023] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a small-diameter steel pipe 3PE external anti-corrosion transmission line includes a plurality of transmission components arranged in a straight line. The transmission component includes a base 1 and a pair of transmission wheels arranged on the base 1. The axes are parallel to each other, the rotation axis of the transmission wheel and the conveying direction of the steel pipe form an included angle α, the size of the included angle α is adjusted according to the conveying speed, generally the size of the included angle α is between 10°-25°.

[0024] At least one transmission wheel is movably mounted on the base 1 to adjust the distance between two adjacent transmission wheels. Wherein the driving wheel comprises a driving wheel 4 and a driven wheel 5, the driving wheel 4 and the driven wheel 5 are distributed on the base 1 left and right, the base 1 is provided with a fixed support 2 and a movable support ...

Embodiment 2

[0028] Embodiment 2: as Figure 4As shown, the difference from Embodiment 1 is that a linkage mechanism 9 is provided between the swing frame 6 and the movable bracket 3, and when the movable bracket 3 moves closer to or away from the fixed bracket 2, the swing frame 6 is driven by the linkage mechanism 9. Swing in the opposite direction. That is, when the movable support 3 moves toward the direction close to the fixed support 2 , the swing frame 6 swings toward the direction away from the fixed support 2 . Linkage mechanism 9 comprises worm gear 91, the worm screw 92 that drives worm gear 91 to rotate, the cylindrical gear 93 that drives worm screw 92 to rotate, and described worm gear 91 is arranged on the rotation center of described swing frame 6, and is fixedly connected with described swing frame 6, The worm 92 is rotatably mounted on the movable bracket 3, the rotation axis of the worm 92 points to the moving direction of the movable bracket 3, and the cylindrical gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com