A vision-guided intelligent sorting method for sausages

A visual guidance, sausage technology, applied in sorting and other directions, can solve the problems of low positioning accuracy, affecting sausage production, weak adaptability, etc., to achieve high sausage identification and positioning accuracy, improve sausage production efficiency, and strong product adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further explained by specific embodiments below. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

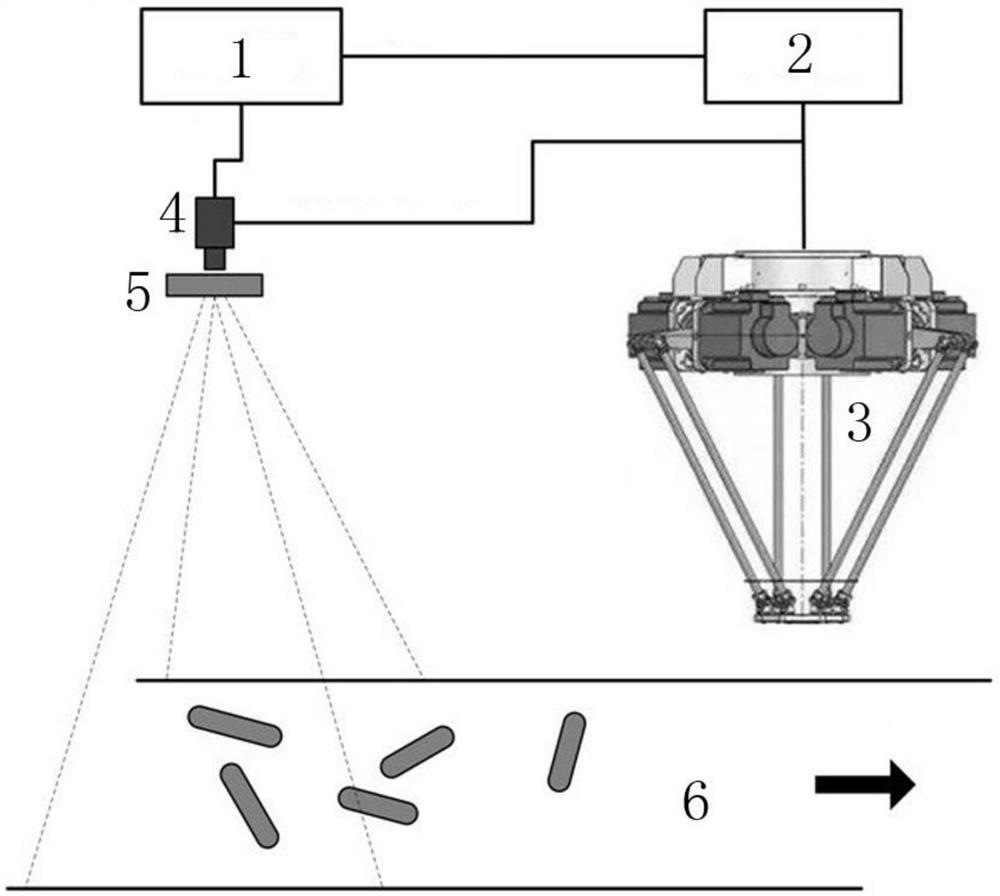

[0047] Such as figure 1 As shown, the sausage automatic sorting system of the present invention is composed of an industrial computer 1, a controller 2, an industrial robot 3, an industrial camera 4, a light source 5, and a conveyor belt 6. The industrial robot 3 is located above the conveyor belt 6, and the industrial camera 4 is fixed on the industrial robot 3 Upstream of the grasping position and directly above the conveyor belt 6, a ring light source 5 is placed directly below the industrial camera 4 to keep the sausage under uniform light. The working principle of the system is: the conveyor belt transports sausages at a certain speed, the light source direction faces the sausages on the conveyor belt, the industrial computer control controller sends a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com