Milling machine tool with blade compensation function

A milling and blade technology, applied in the field of milling machine tools with blade compensation, can solve the problems of easy residue of material chips, overflow, and clogging of material chips, and achieve the effect of simple structure, prolonging service life and reducing failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

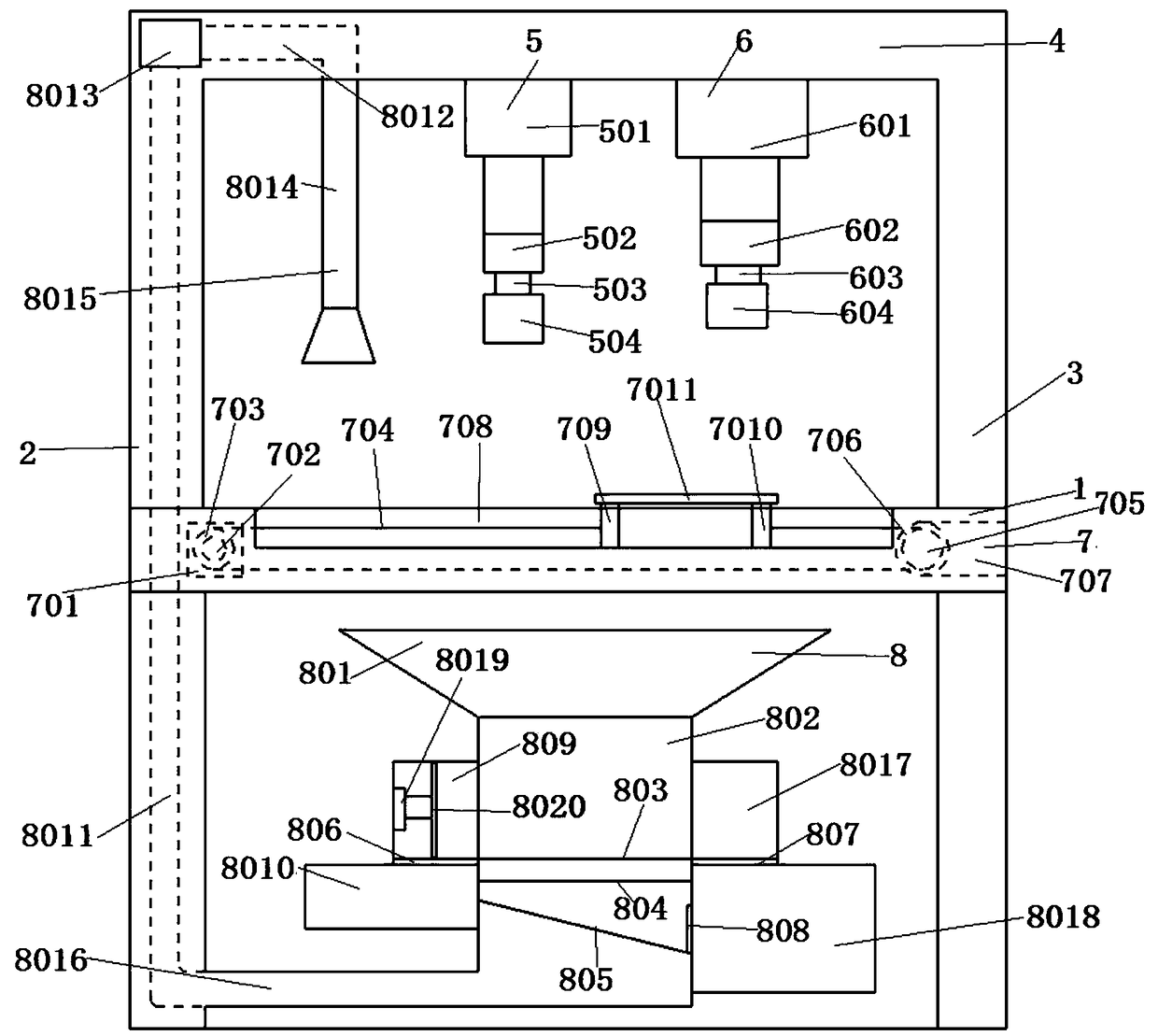

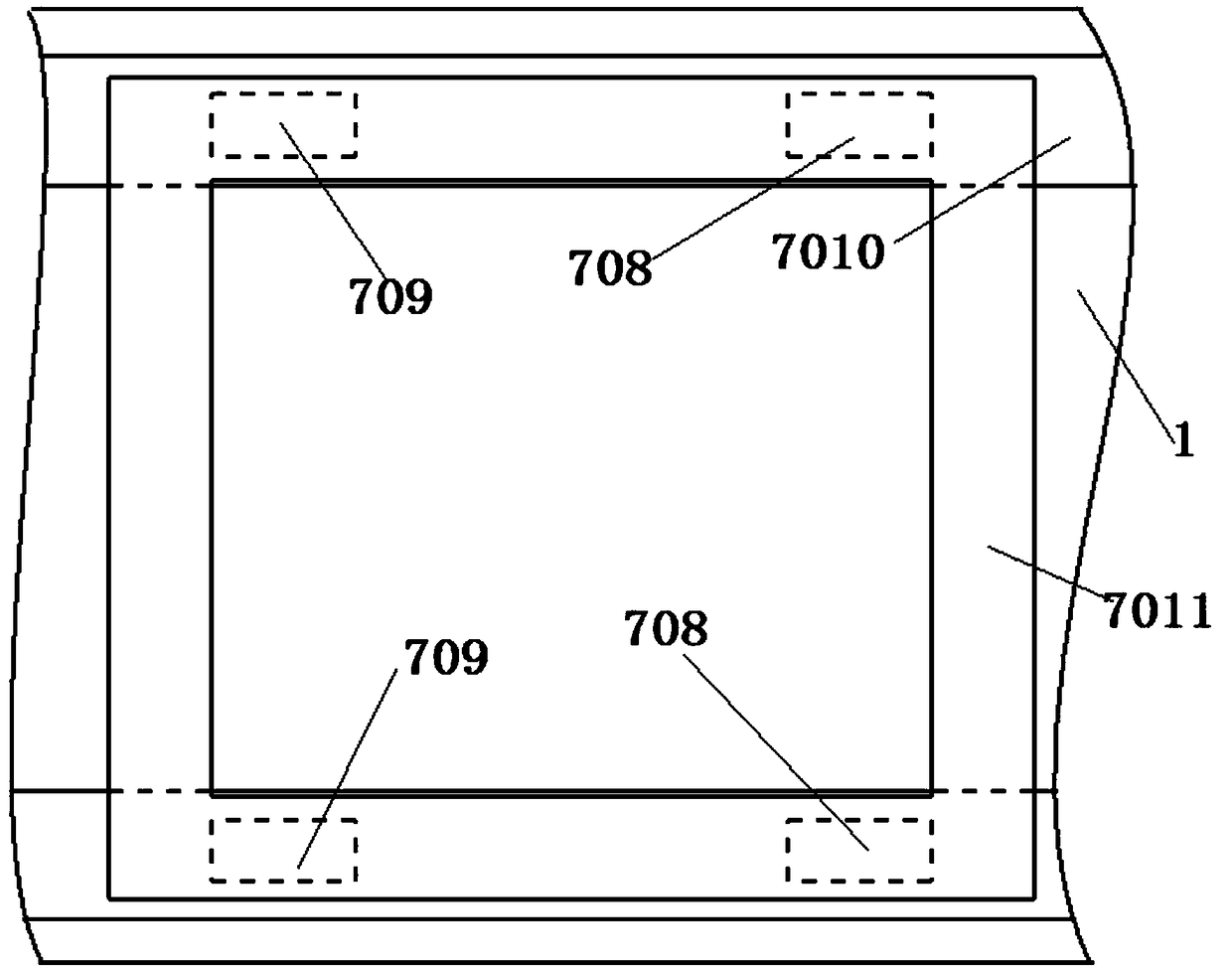

[0022] A milling machine tool with blade compensation, including a support plate 1, a first support column 2, a second support plate 3, a top plate 4, a rough milling assembly 5, a fine milling assembly 6, a moving assembly 7 and a recovery assembly 8, the first support column The middle part of 2 is connected with the middle part of the second support plate 3 through the support plate 1, the moving assembly 7 is arranged on the support plate 1, the recovery assembly 8 is arranged under the support plate 1, the upper end of the first support column 2 and the upper end of the second support plate 3 pass through the top plate 4 connection, the middle part of the lower end of the top plate 4 is connected with a fine milling assembly 6, and one side of the fine milling assembly 6 is provided with a rough milling assembly 5 connected with the top plate 4; the recovery assembly 8 includes a left waste material transition box 809 and a right waste material transition box 8017, and a le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com