Welding process for hot pipe

A welding process and heat pipe technology, which is applied in welding equipment, manufacturing tools, heat exchange equipment, etc., can solve the problems that the welding liquid penetrates into the liquid absorption core and affects the liquid absorption effect, and achieves the effect of avoiding welding and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

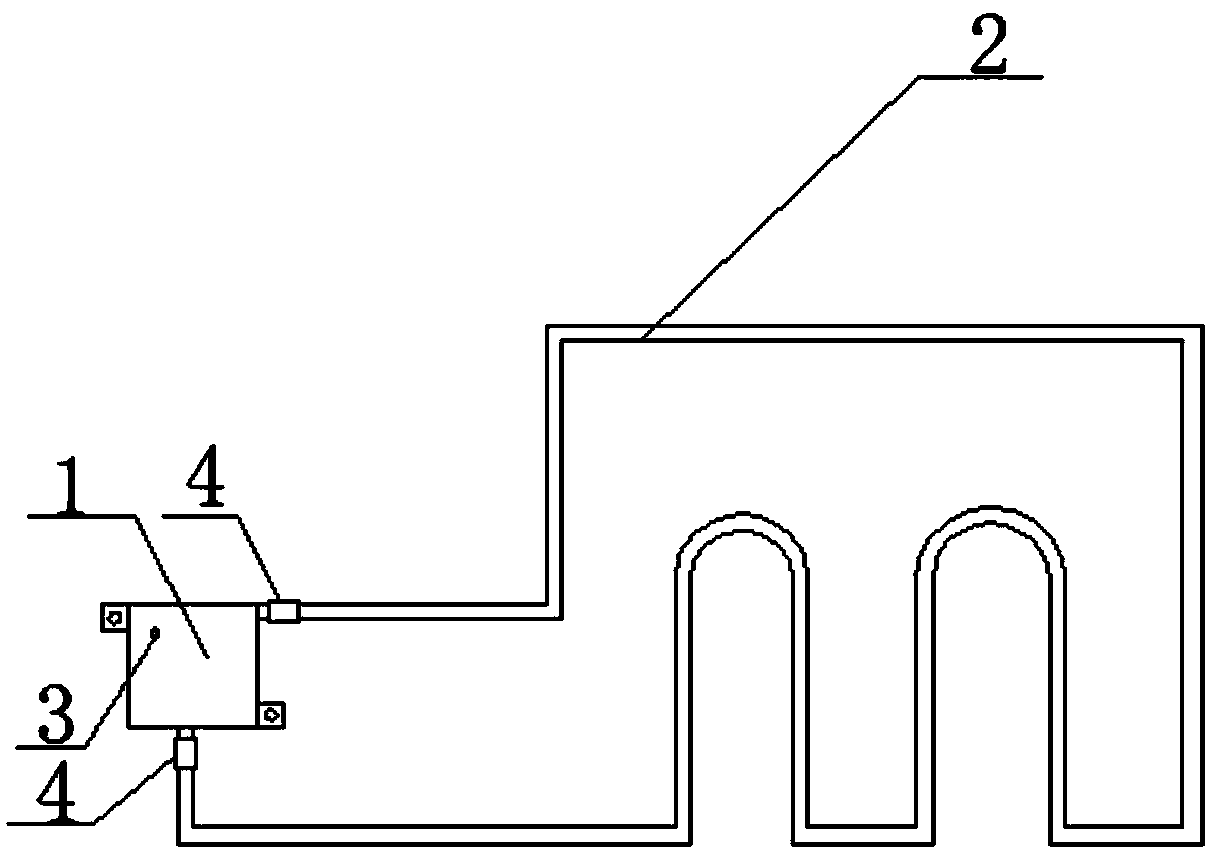

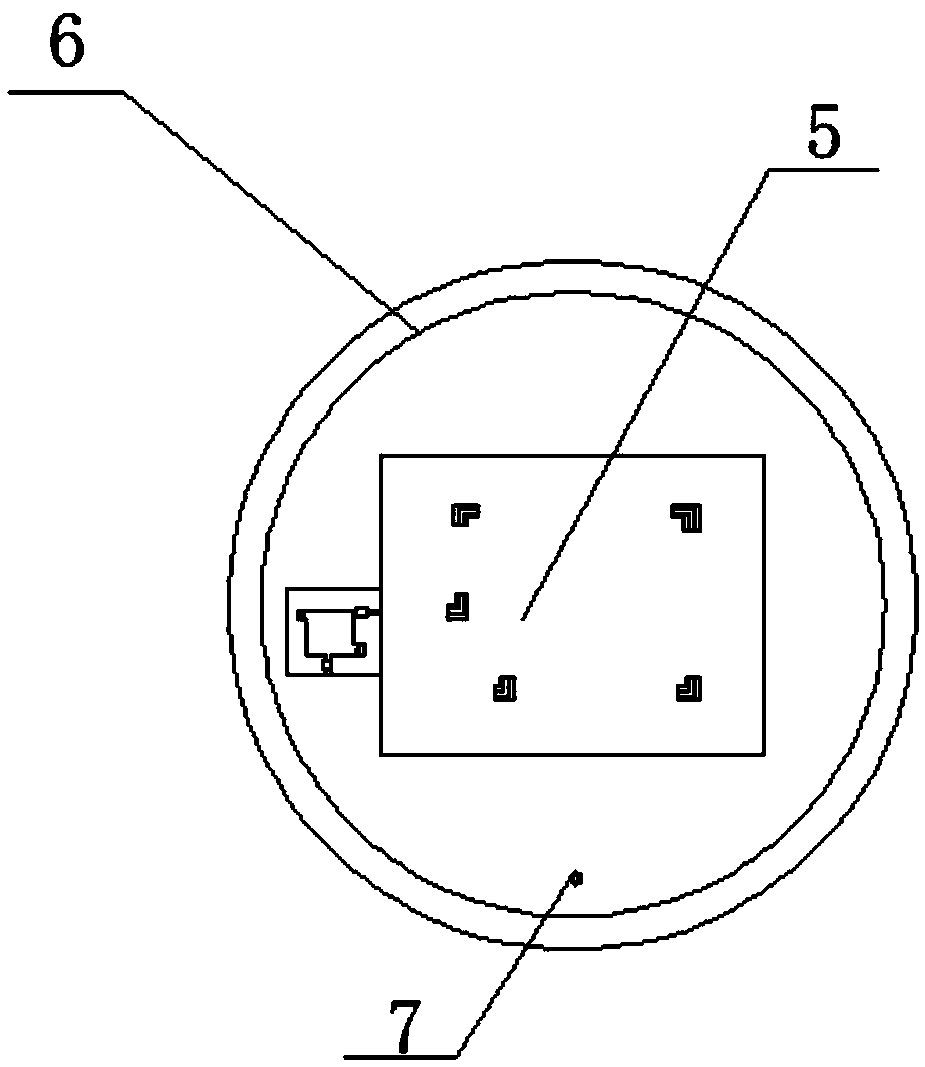

[0026] The present invention proposes a welding process for heat pipes, such as figure 1 As shown, the two ends of the connecting pipe 4 are the main welding parts. For the sake of installation and heat dissipation, the cross-section of the general heat pipe is rectangular, the heat-absorbing part is relatively concentrated, and the condensing part is long. The following steps are included:

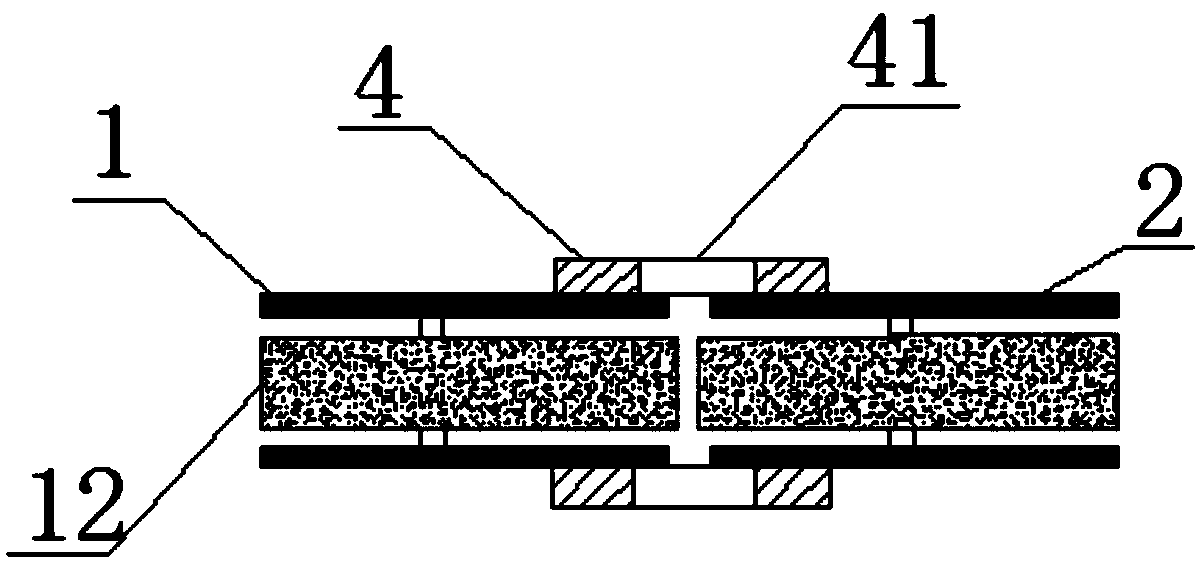

[0027] First, surface treatment is carried out on the evaporation section 1, condensation section 2 and connecting pipe 4, the surface treatment includes grinding, cleaning and drying the outer surfaces near the ends of the evaporation section 1 and condensation section 2, and grinding the inner and outer surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com