Cylindrical coordinate type automatic feeding and discharge mechanical hand

A technology of automatic loading and unloading and cylindrical coordinates, applied in the field of manipulators, can solve the problems of large vibration and error, inability to meet enterprises, low work efficiency, etc., and achieve the effect of simple and compact structure, small space occupation, and labor intensity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

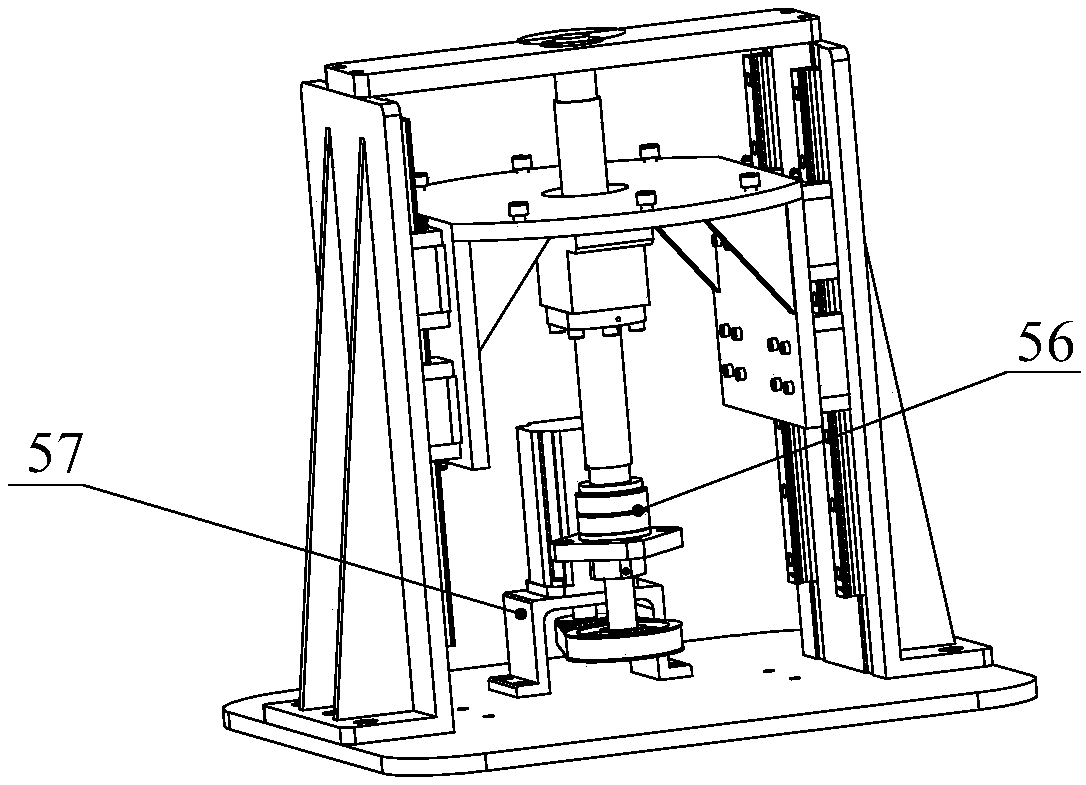

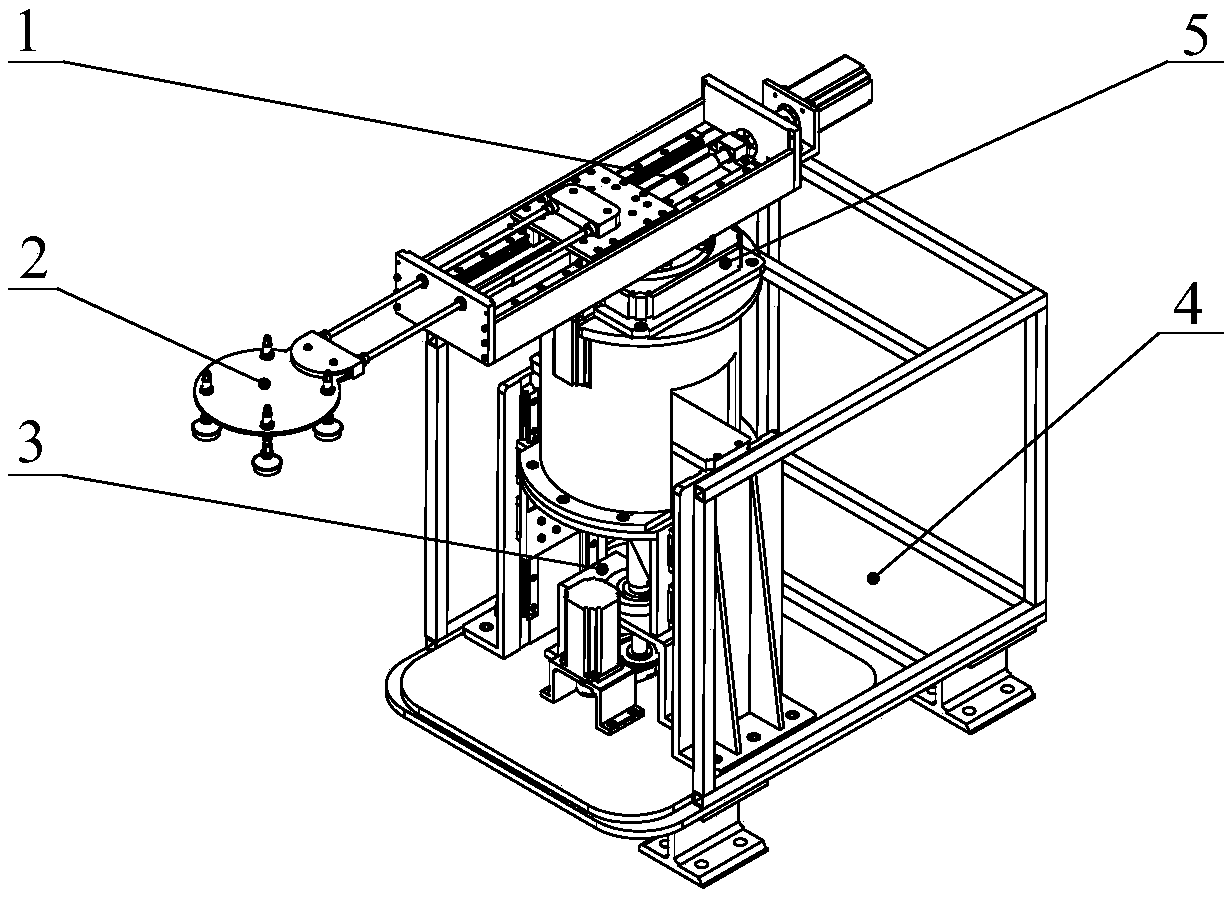

[0026] Such as figure 1 As shown, a cylindrical coordinate type automatic loading and unloading manipulator includes a sucker-type mechanical arm mechanism 2, a horizontal movement mechanism 1 for driving the manipulator to move horizontally, a rotating mechanism 5 for driving the manipulator to rotate, and a lifting mechanism 3 for driving the manipulator to move up and down. The box body 4 of manipulator, wherein:

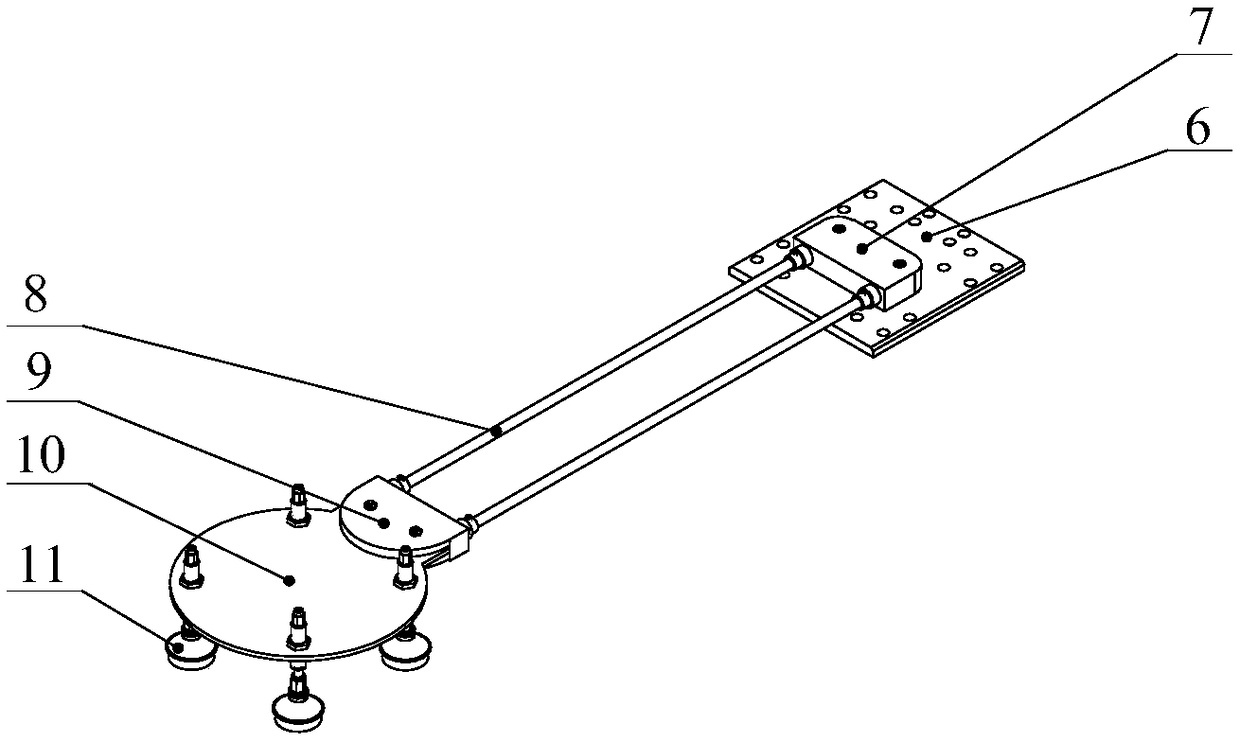

[0027] Such as figure 2 As shown, the sucker-type mechanical arm mechanism 2 includes a horizontally arranged slider fixing plate 6, the polished rod fixing plate 7 is installed on the slider fixing plate 6, and the right ends of two parallel polished rods 8 are installed on the left end surface of the polished rod fixing plate 7. A parallel light rod 8 passes through the sealing plate 27, and the left ends of the two parallel light rods 8 are connected to the holder bracket 9, the suction cup holder 10 is installed on the holder holder 9, and four suction cups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com