Low-speed driving device of electric block double-speed motor

A technology of two-speed motor and electric hoist, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of increased viscosity of grease, poor fluidity of grease, difficulty in adding and changing grease, etc. To achieve the effect of preventing tooth surface wear, reducing power loss, and stable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

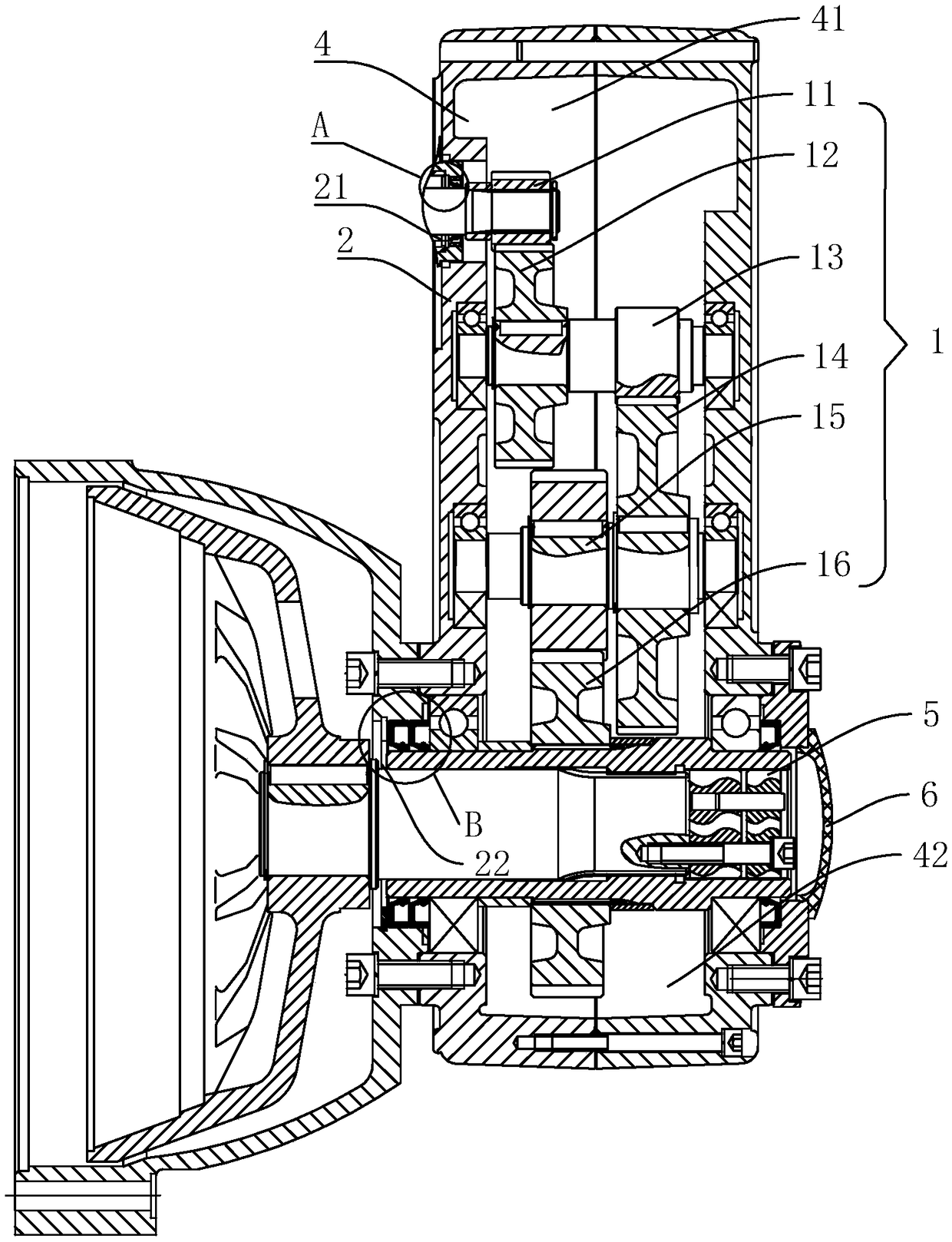

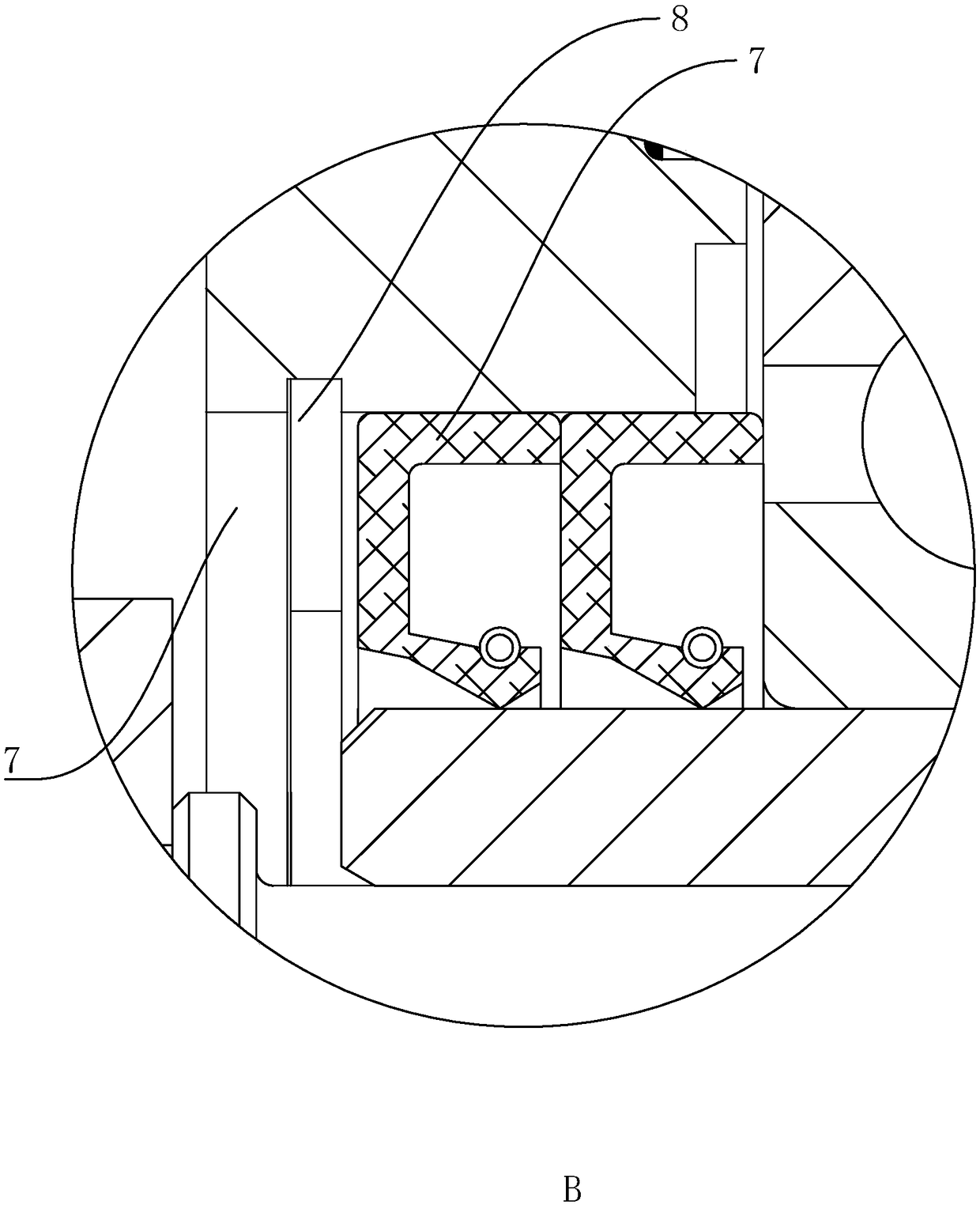

[0023] This embodiment provides an electric hoist two-speed motor slow drive device, the structure is as follows figure 1 As shown, an electric hoist two-speed motor slow drive device is connected between the main hoisting motor and the auxiliary hoisting motor, including a wheel set 1 for linking the main hoisting motor and the auxiliary hoisting motor. 1 is provided with a closed casing 2, and the wheel set 1 is lubricated with oil.

[0024] The same side of the closed shell 2 is provided with the output shaft interface 22 of the main lifting motor and the output shaft interface 21 of the auxiliary lifting motor. The diameter of the output shaft interface 22 of the main lifting motor is greater than the diameter of the output shaft interface 21 of the auxiliary lifting motor.

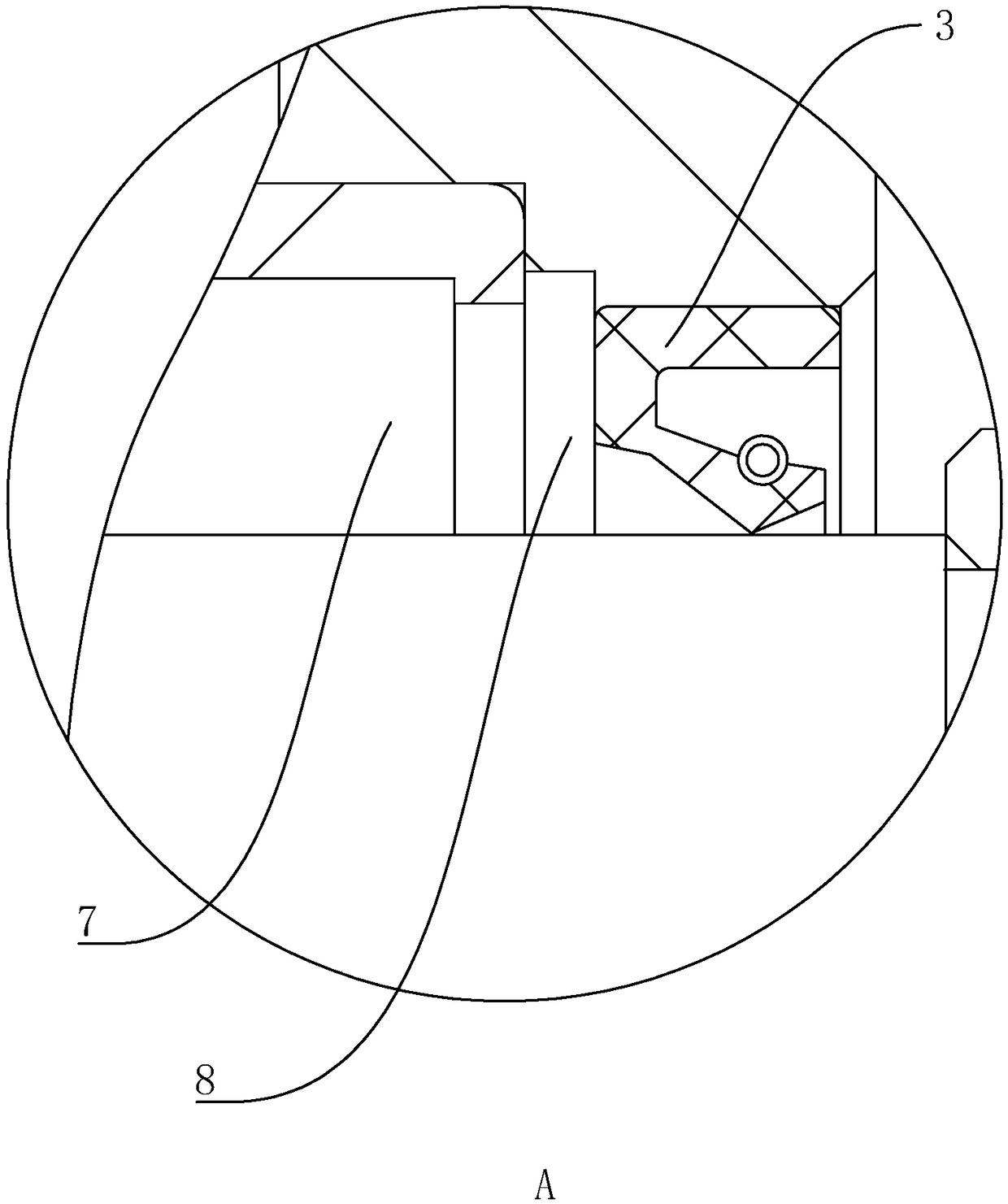

[0025] The output shaft interface 22 of the main hoisting motor is provided with sealing gaskets 3 , and the number of sealing gaskets 3 here is more than that of the output shaft interface 21 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com