Preparation method of durable high-strength composite concrete expansive material

A high-strength concrete technology, applied in the field of expansion agent, can solve the problems of poor durability and achieve the effect of improving durability and compensating shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

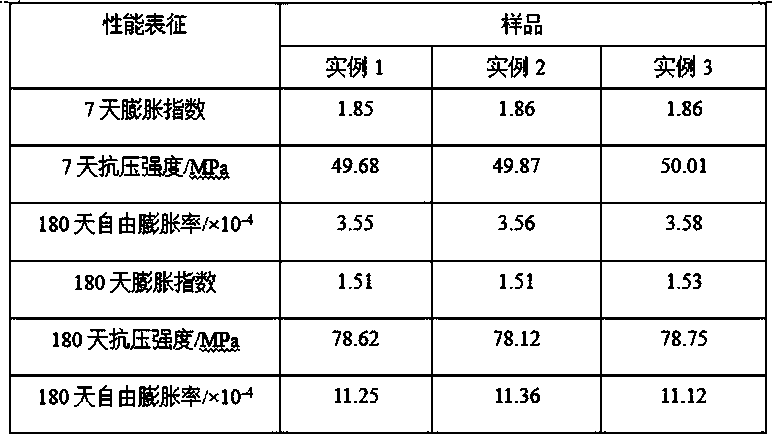

Examples

Embodiment Construction

[0016] Take the sepiolite and wash it, dry it, and ball mill it for 10-12 hours, collect the ball-milled particles, mix the ball-milled particles with 0.1% hydrochloric acid in a mass fraction of 1:5, and place them at 75-80°C for 10-12 hours. Let stand to cool to room temperature, then centrifuge at 1200-1500r / min for 10-15min, collect the lower sediment and mix the lower sediment, blast furnace slag and composite magnesium oxide particles according to the mass ratio of 1:1:1, and ball mill for 1- After 2 hours, collect the mixed ball milling particles and place them in a crucible, place the crucible at 120-125°C and dry for 3-5 hours, then raise the temperature at 5°C / min to 1400-1500°C, heat-preserve and calcinate for 1-2 hours, collect and melt Liquid and wire-drawing treatment, the drawn fiber was collected and naturally cooled to room temperature to obtain modified fiber; in parts by weight, weigh 45-50 parts of acrylamide, 0.1-0.2 parts of cross-linking agent dicumyl per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com