A method for rapidly extracting high-purity low-molecular-weight chitin from shrimp and crab shells

A low-molecular-weight, shrimp and crab shell technology is applied in the field of rapid extraction of high-purity low-molecular-weight chitin, which can solve the problems of poor biodegradability, large environmental pollution, and high production costs, and achieve the effects of short time, low price, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

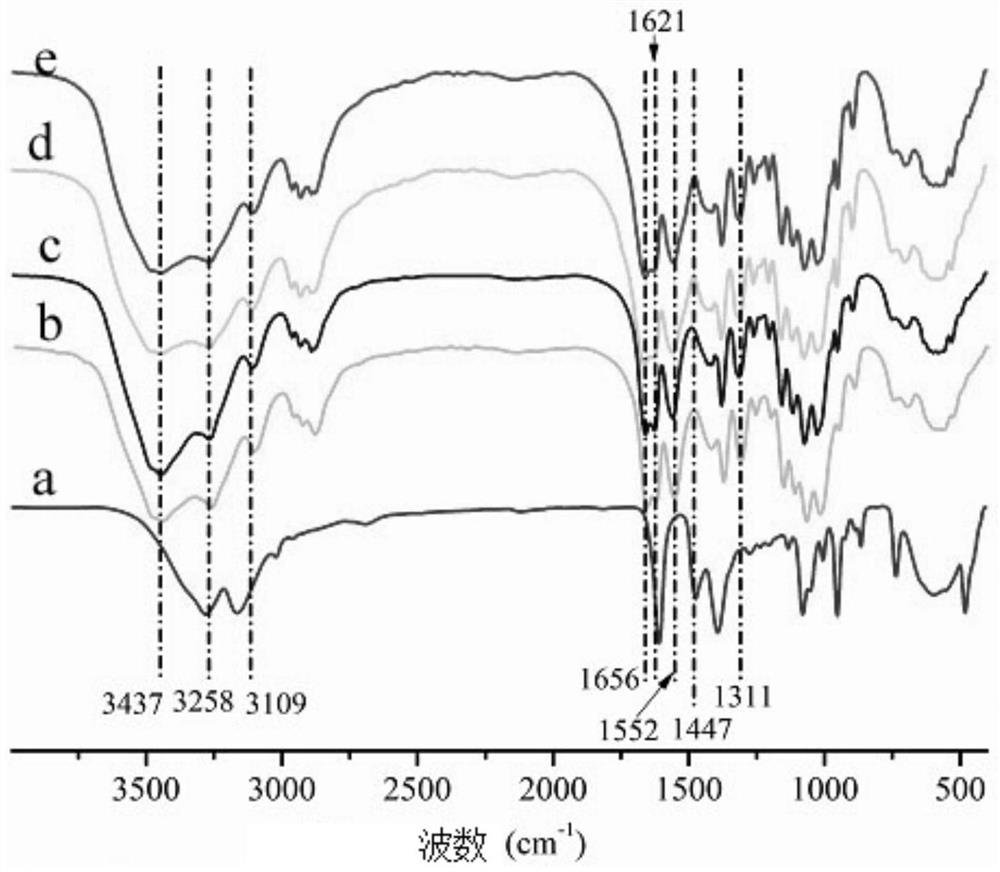

Image

Examples

Embodiment 1

[0020] (1) Pre-treatment of lobster shells: remove foreign matter on the inner and outer surfaces of lobster shells, rinse repeatedly with water, soak in ethanol solution, dry, grind, and sieve after rinsing with water, and take lobster shell powder below 100 mesh for use;

[0021] (2) Preparation of mixed solvent: Mix glycerin and hydrochloric acid solution in parts by weight and place in a reaction vessel, stir evenly at room temperature to obtain a mixed solvent with a mass concentration of hydrochloric acid of 5% for later use;

[0022] (3) Mix the lobster shell powder obtained in step (1) with the mixed solvent at a mass ratio of 1:10, stir and react at a set temperature of 120°C for 2 hours to obtain a reaction product;

[0023] (4) Add the reaction product obtained in step (3) into distilled water and cool it down, centrifuge it in a high-speed centrifuge at a speed of 4000r / min for 5 minutes, wash it repeatedly until it is nearly neutral, and dry the precipitate to obta...

Embodiment 2

[0025] (1) Pre-treatment of lobster shells: remove foreign matter on the inner and outer surfaces of lobster shells, rinse repeatedly with water, soak in ethanol solution, dry, grind, and sieve after rinsing with water, and take lobster shell powder below 100 mesh for use;

[0026] (2) Preparation of mixed solvent: Mix glycerin and hydrochloric acid solution in parts by weight and place in a reaction vessel, stir evenly at room temperature to obtain a mixed solvent with a mass concentration of hydrochloric acid of 7% for later use;

[0027] (3) Mix the lobster shell powder obtained in step (1) with the mixed solvent at a mass ratio of 1:10, stir and react at a set temperature of 120°C for 2 hours to obtain a reaction product;

[0028] (4) Add the reaction product obtained in step (3) into distilled water and cool it down, centrifuge it in a high-speed centrifuge at a speed of 4000r / min for 5 minutes, wash it repeatedly until it is nearly neutral, and dry the precipitate to obta...

Embodiment 3

[0030] (1) Pre-treatment of lobster shells: remove foreign matter on the inner and outer surfaces of lobster shells, rinse repeatedly with water, soak in ethanol solution, dry, grind, and sieve after rinsing with water, and take lobster shell powder below 100 mesh for use;

[0031] (2) Preparation of mixed solvent: Mix glycerin and hydrochloric acid solution in parts by weight and place in a reaction vessel, stir evenly at room temperature to obtain a mixed solvent with a mass concentration of hydrochloric acid of 9% for later use;

[0032] (3) Mix the lobster shell powder obtained in step (1) with the mixed solvent at a mass ratio of 1:10, stir and react at a set temperature of 120°C for 2 hours to obtain a reaction product;

[0033] (4) Add the reaction product obtained in step (3) into distilled water and cool it down, centrifuge it in a high-speed centrifuge at a speed of 4000r / min for 5 minutes, wash it repeatedly until it is nearly neutral, and dry the precipitate to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com