Patents

Literature

208 results about "Hydrolysed protein" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A protein hydrolysate refers to a protein that has been partially digested or "hydrolyzed.". Don't worry, it's not as if someone began chewing your protein and spat it back out. This process involves adding proteolytic enzymes, which break down protein, or heating a protein with acid.

Infant formula with improved protein content

InactiveUS6863918B2Promote absorptionPrevent and reduce regurgitationVitamin food ingredientsHydrolasesHydrolysateConstipation

An improved infant formula resulting in reduced constipation, abdominal discomfort and gastrointestinal problems, comprises at least one protein component having a phosphorus content of less than 0.75 g P / 100 g protein, and at least one lipid component that can be easily digested by an infant. Preferably, it further comprises at least one prebiotic component, and at least one viscosity-improving component. The protein fraction of the formula is preferably a hydrolysate prepared by hydrolysing a protein starting material, especially a whey protein with a combination of at least one endo- and at least one exoproteinase.

Owner:NUTRICIA

Infant nutrition with hydrolised proteins

InactiveUS20090203592A1Lower Level RequirementsPromote growthDipeptide ingredientsMetabolism disorderPhysiologyNutrition

The invention concerns a method to treat and / or prevent childhood obesity comprising administering a nutritional composition containing fat, digestible carbohydrates and protein, wherein the protein comprises at least 25 wt. % peptides with a chain length of 25 to 30 amino acids based on dry weight of protein.

Owner:NV NUTRICIA

Pig homologous raw material-free attracting starter compound feed for porkets

ActiveCN102389061AKeep the original scentIncrease total intakeAnimal feeding stuffBiotechnologyWeight gaining

The invention discloses pig homologous raw material-free attracting starter compound feed for porkets. According to a technical scheme adopted by the invention, the feed is composed of the following raw materials by weight percent: 35-45% of a puffed raw material, 5-8% of a soybean protein concentrate, 10-15% of fermented soybean meal, 4-5% of hydrolyzed wheat protein, 6-10% of lactose, 4-8% of whole milk powder, 3-5% of a casein, 2-5% of a nucleotide, 2-5% of fish meal, 1-3% of amino acid, 0.5-2% of glutamine, 0.5-1% of an acidifying agent, 2-5% of plant oil, 0.02-0.1% of a composite vitamin, and 0.1-0.5% of a composite trace element. Application of the feed in the invention presents strong feed attraction to porkets which can start feed taking in1-2d with rapidly increasing intake. With balanced and comprehensive nutrition similar to breast milk, the feed provided in the invention is characterized by high digestibility in porkets, no diarrhoea, effective overcoming of weaning stress, and rapid weight gain, and can effectively increase the porket weaning weight and the weight after two weeks of weaning, as well as improve porket survival rate and production performance. Free of plasma protein powder, dried porcine soluble and other pig homologous raw materials, the feed of the invention has no risk of homologous pig pathogen infection, and boasts significant biosecurity.

Owner:HARBIN QINGHE TECH

Nibea albiflora richardson larvae and juvenile microcapsule feed, as well as processing preparation and feeding method thereof

ActiveCN102845653AClear in timeMeeting nutritional needsClimate change adaptationAnimal feeding stuffAnimal scienceHydrolysate

The invention provides a nibea albiflora richardson larvae and juvenile microcapsule feed which is prepared from white fish meal, euphausiid meal, squid meal, fish protein hydrolysate, feed yeast, alpha-starch, soybean lecithin, papain, fish oil, composite vitamin, composite mineral substance, binder, immunopotentiator, phagostimulant and the like. By adopting the innovated prescription and processing process, the microcapsule feed can fulfill the requirement for nutrition of larvae and juvenile growth, has the advantages of comprehensive nutrition, good palatability, high water stability, low cost and the like, can be produced in batches, is convenient for storing, transporting and feeding, is suitable for industrial breeding production, and adopts a corresponding feeding method, so that the survival rate of nibea albiflora richardson is greatly improved, the shape of the nibea albiflora richardson is increase. The nibea albiflora richardson larvae and juvenile microcapsule feed is suitable for large-scale popularization and application.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Gi Track Delivery Systems

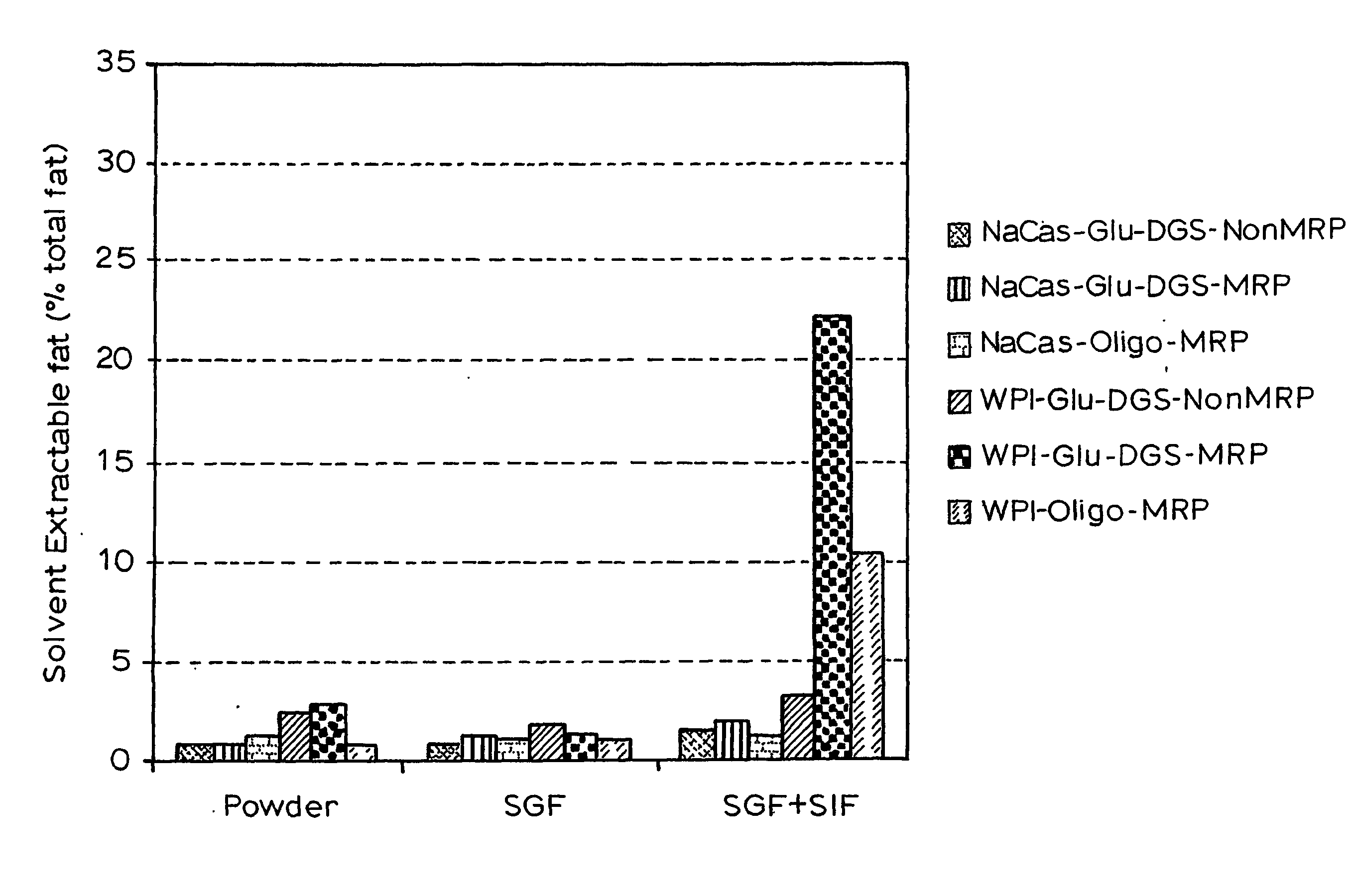

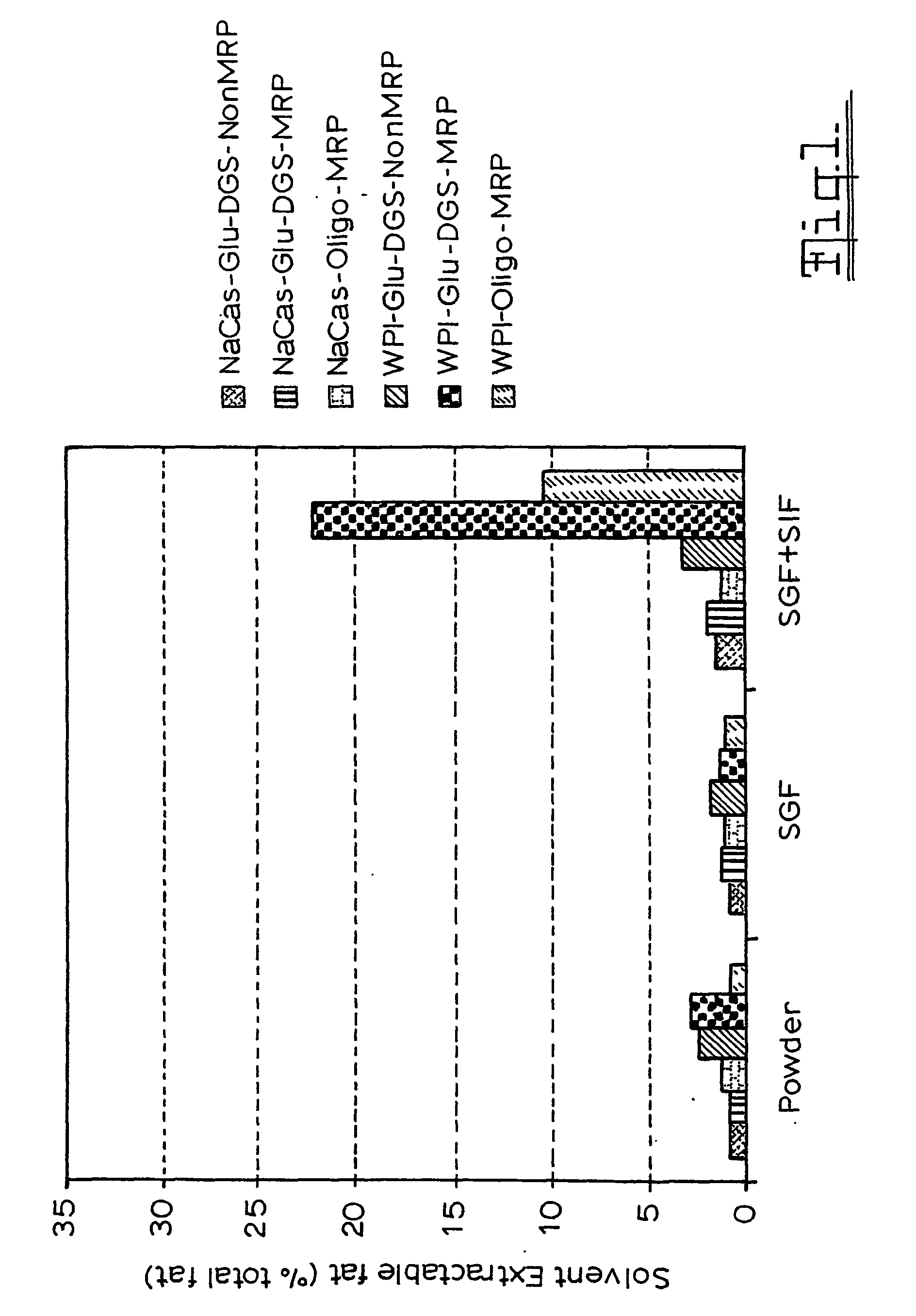

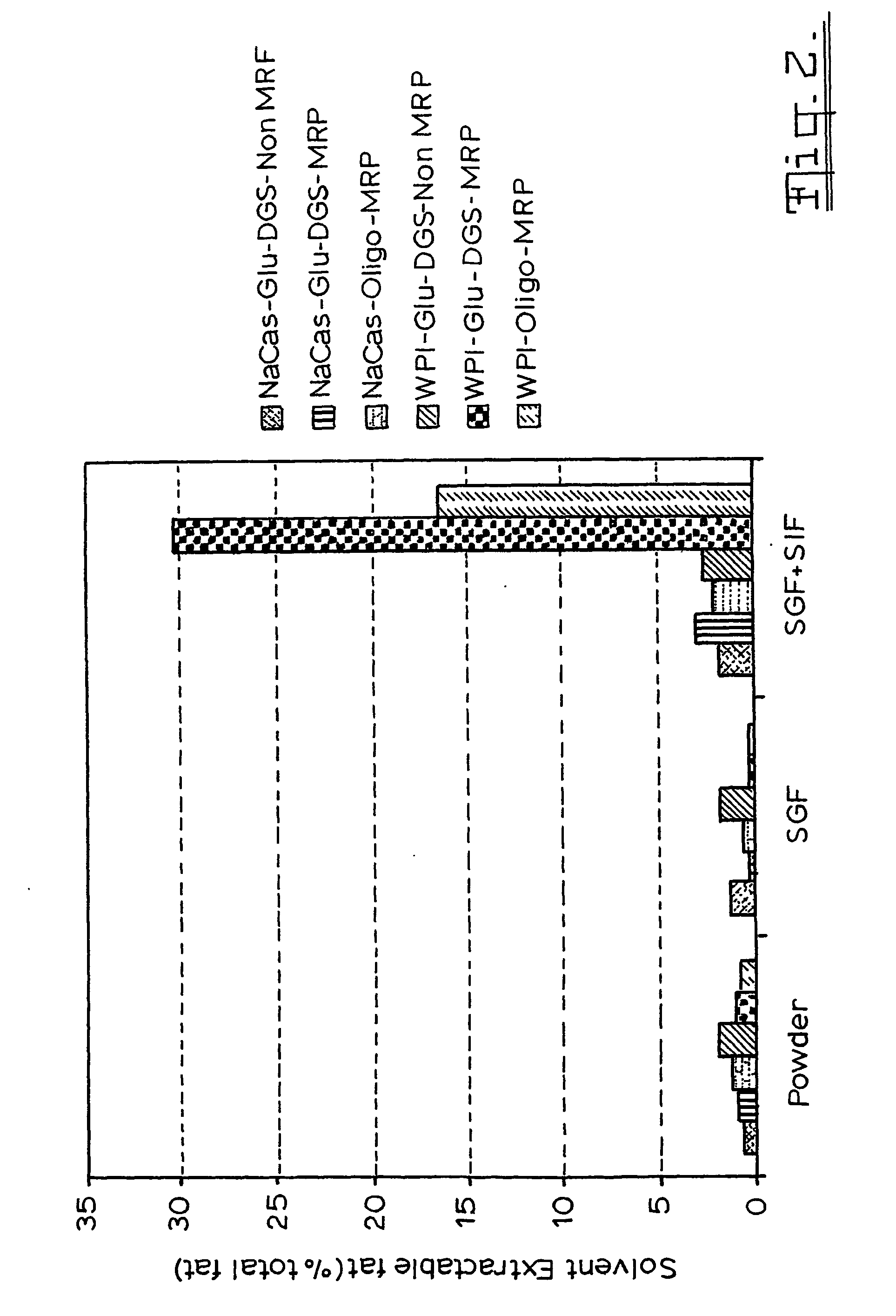

ActiveUS20070218125A1Effective matrixEasy to adaptSugar food ingredientsMetabolism disorderLipid formationAdditive ingredient

A micro encapsulation material for use with storage unstable, therapeutic and nutritional agents which release the therapeutic and nutritional agents in predetermined locations in the gastro intestinal tract in which the microencapsulation material is formed by combining a food grade treated carbohydrate with a water soluble food grade protein. The therapeutic and nutritional agents form an oil phase which is emulsified with the water dispersed or dissolved encapsulant to encapsulate the therapeutic and nutritional agents. These agents may be oils or oil soluble or oil dispersible. The agents that may be encapsulated Include lipids (oils Including oxygen sensitive oils, fatty acids, triglycerides) and oil soluble and oil dispersible ingredients (including pharmaceuticals, probiotics, protein therapeutics and bioactives). The protein used may include any film forming water soluble protein or hydrolysed protein and includes milk proteins such as casein and its derivatives or whey proteins. The carbohydrate component may be those containing reducing sugar groups, oligosaccharides and starches (raw, modified, resistant, acetylated, proprionated and butyrated starches).

Owner:COMMONWEALTH SCI & IND RES ORG

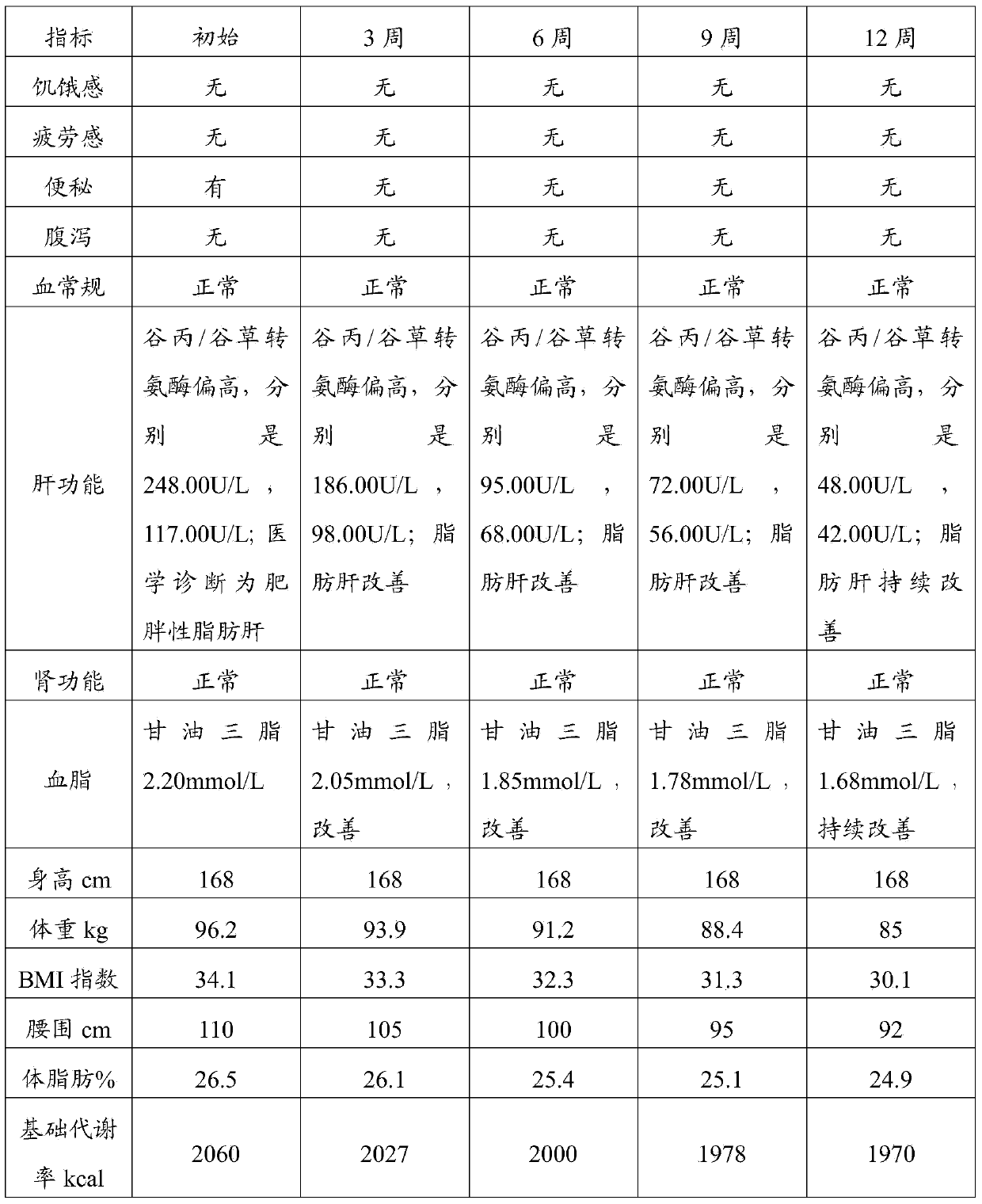

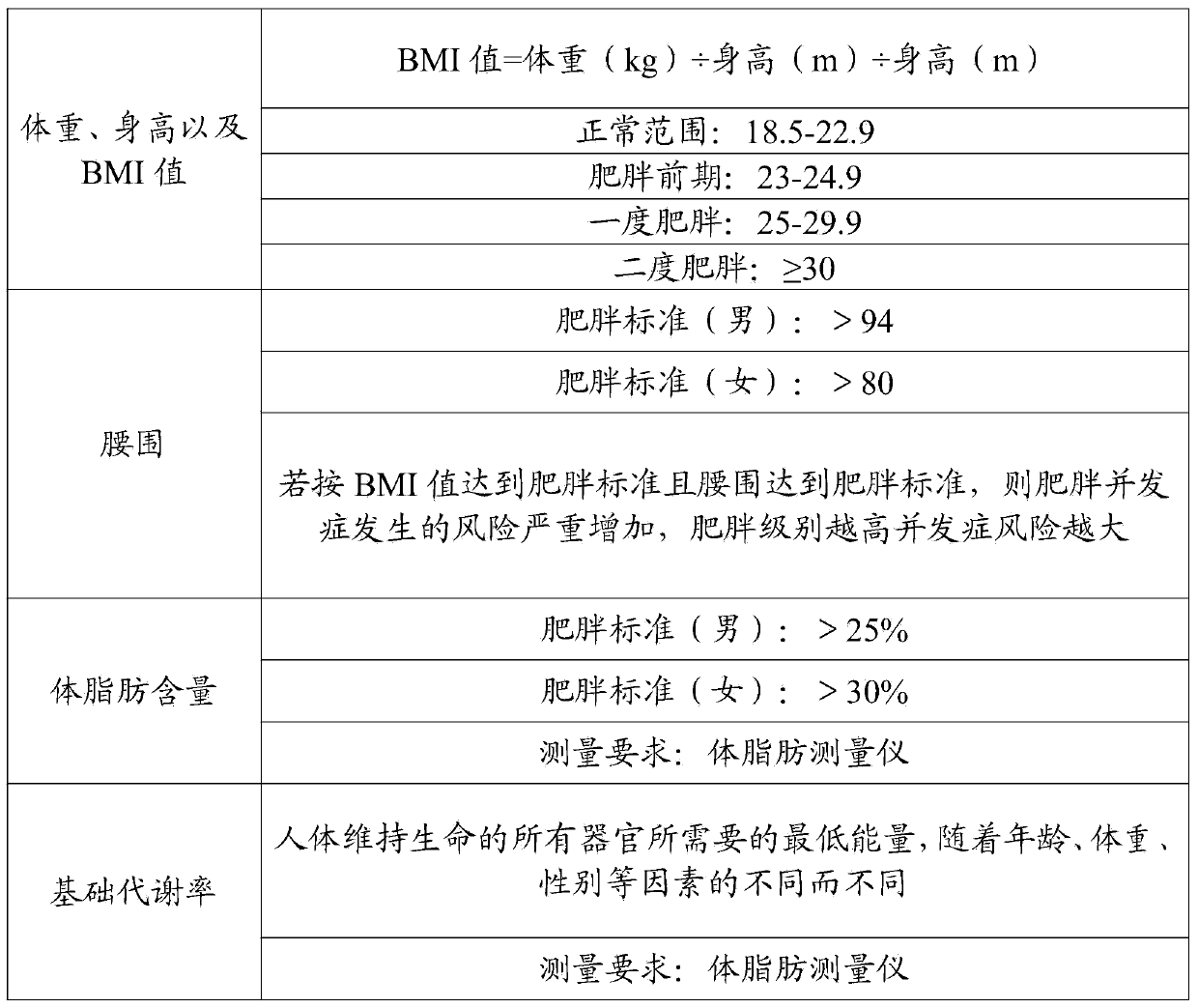

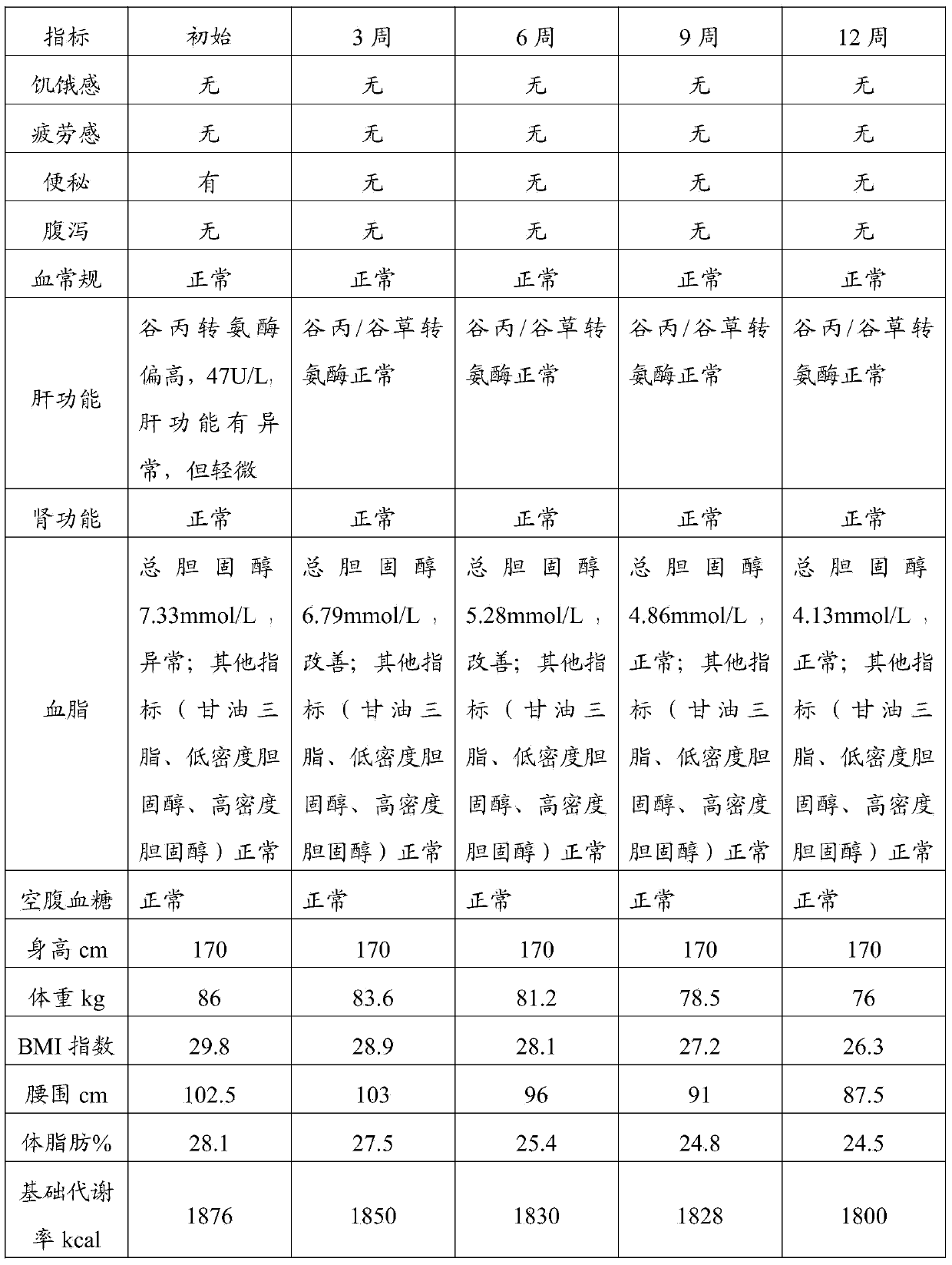

Dietetic food composition for losing weight

ActiveCN103719852AControl intakeControl ingredientSugar food ingredientsFood ingredient functionsBiotechnologyVegetable oil

The invention discloses a dietetic food composition for losing weight. The composition comprises the following ingredients: fresh meat and aquatic product, vegetables, fruits, dried mushroom products, cereals, beans, nut meat, edible vegetable oil, eggs, protein hydrolysate powder, dietary fiber powder, konjac powder, guar gum, polyols, phosphatidylcholine, fruit polyphenols, L-carnitine, vitamin A, vitamin E, vitamin C, thiamine hydrochloride, riboflavin, nicotinamide, pyridoxine hydrochloride, folic acid, cyanide-containing cobalt and pantothenic acid. By adopting the dietetic food composition disclosed by the invention, the total energy intake is reduced under the premise of ensuring normal basic metabolic rate, the requirements of the body on protein at a low-energy diet period are improved, and related nutrients are replenished to facilitate body fat, visceral fat and blood lipid metabolism, so as to achieve the target of losing weight. Meanwhile, the invention also discloses a preparation method of the dietetic food composition and use of the dietetic food composition in preparation of a medicament for preventing or treating an obesity disease.

Owner:GUANGZHOU CINJEP BIOTECH

Method for extracting shinyleaf yellowhorn oil, shinyleaf yellowhorn polysaccharide and shinyleaf yellowhorn protolysate peptide from shinyleaf yellowhorn

InactiveCN101948897ANo emissionsOptimistic about market consumption prospectsAnimal feeding stuffFermentationUltrafiltrationCellulase

The invention belongs to the deep processing technology of shinyleaf yellowhorn, in particular to a method for extracting shinyleaf yellowhorn oil, shinyleaf yellowhorn polysaccharide and shinyleaf yellowhorn protolysate peptide from shinyleaf yellowhorn. The method comprises the following steps of: taking the kernels of shinyleaf yellowhorn, crushing the shinyleaf yellowhorn kernels, and adding water to swell; continuously treating by using microwaves, hydrolyzing by using alkali protease, separating three phases by using neutral protease, flavourzyme, cellulase and hemicellulase, concentrating through ultrafiltration by using an ultrafiltration membrane, drying the concentrated solution, and vacuum-drying and crushing the hydrolyzing residue to obtain high-grade animal feed rich in protein, fat and cellulose. In a word, the invention overcomes various defects caused by the traditional vegetable oil preparation process and adopts a brand new process for furthest extracting pollution-free shinyleaf yellowhorn oil and simultaneously acquiring shinyleaf yellowhorn polysaccharide and shinyleaf yellowhorn protolysate peptide. The whole processing process reflects continuity, rapidnessand mechanization, and production efficiency is greatly improved.

Owner:山西金绿禾燕麦研究所

Preparation method of small molecule peptides of vinasse and application of small molecule peptides of vinasse in skin care products

ActiveCN107988297AHigh extraction rateImprove moisturizing functionCosmetic preparationsToilet preparationsFiltrationDissolution

The invention provides a preparation method of small molecule peptides of vinasse and application of small molecule peptides of vinasse in skin care products. The preparation method comprises the following steps: S1, carrying out vacuum extrusion, cooling, crushing and sieving on vinasse, the water content of which is 11-22%; S2, carrying out alkali dissolution and acid settlement on the vinasse expanded powder obtained in the S1 to extract vinasse proteins so as to obtain vinasse protein extract; and S3, carrying out hydrolysis on the vinasse protein extract extracted in the S2 with proteolytic enzymes, and carrying out enzyme deactivation, filtration, concentration, freezing and drying to obtain the small molecule peptides of vinasse. By deeply processing the vinasse by adopting a special vacuum expansion technology, the extraction ratio of the vinasse proteins is increased effectively; meanwhile, by adopting the special proteolytic enzymes, the small molecule peptides of vinasse with relatively good moisturizing and repairing functions can be obtained. In addition, the small molecule peptides of vinasse are applied to skin care products, so that the moisturizing and repairing functions of the skin care products are improved while the additional value of the vinasse is increased.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

A method for efficiently extracting endocrine disruptors in samples

InactiveCN102288709AIncrease flow rateEfficient extractionComponent separationInorganic saltsPerturbateurs endocriniens

In the method for efficiently extracting endocrine disruptors in a sample of the present invention, the sample to be tested is preliminarily treated by filtering, grinding, homogenizing, ultrasonication, protein precipitation, protein hydrolysis or degreasing to make a sample solution of an aqueous matrix; adjust the pH value of the sample solution, Or add inorganic salts or organic salts to increase the ionic strength of the sample solution to reduce the distribution coefficient of endocrine disruptors in the water phase; use the membrane disc solid phase extraction device to make the sample solution flow continuously or "flow-stop-flow" intermittent Through the activated nylon nanofiber membrane, the endocrine disruptors in the sample are retained by the nylon nanofiber to achieve extraction. The invention synergizes the advantages of solid-phase membrane extraction and nano-adsorption media, and can realize efficient extraction of internally distributed interfering substances in various actual samples with only a few milligrams of nylon nanofiber membrane and hundreds of microliters of elution solvent , The extraction and enrichment process of separation, adsorption, concentration and elution can be completed within a few minutes to ten minutes.

Owner:SOUTHEAST UNIV

Immune type protein powder solid beverage and preparation method thereof

ActiveCN104522832AImprove absorption rateHigh purityNatural extract food ingredientsFood ingredient functionsWhey proteinGamma-Aminobutyric acid

The invention discloses an immune type protein powder solid beverage and a preparation method thereof and belongs to the field of nutritional foods. The solid beverage comprises the following components: 70-85 percent of concentrated whey protein powder, 3-8 percent of pea protein, 5-15 percent of wheat protolysate, 2-4 percent of phospholipid, 1-3 percent of an acerola cherry extract, 1-5 percent of edible essence, 0.5-1.5 percent of a yeast extract, 0.5-1.5 percent of gamma-aminobutyric acid, 0.5-1.5 percent of coconut milk powder, 0.3-0.8 percent of silicon dioxide and 0.1-0.3 percent of stevioside. The invention also discloses the preparation method of the solid beverage. The solid beverage disclosed by the invention fully meets the demands of the human body, is scientific in prescription design, reasonable in nutrition arrangement and different in taste according to different customers, and can meet the special demands of different people on taste; the solid beverage is mellow in taste, convenient to use, stable in quality, simple in preparation method, easy to operate, suitable for large-scale industrial production, free of sugar in the prescription and suitable for diabetics to eat.

Owner:JIANGSU ALAND NOURISHMENT

Blood sugar-reducing composite protein powder and preparation method thereof

InactiveCN104305225AFull of nutritionHypoglycemicMicroorganism/unicellular-algae proteins working-upFood preparationBiotechnologyFreeze-drying

The invention discloses blood sugar-reducing composite protein powder which consists of the following raw materials in parts by weight: 100-150 parts of hydrolyzed soy protein powder, 100-150 parts of hydrolyzed animal protein powder, 80-90 parts of skim peanut protein powder, 40-50 parts of corn protein powder, 40-60 parts of seabuckthorm seed protein powder, 100-200 parts of whey protein powder, 20-30 parts of mulberry leaf freeze-dried powder, 50-60 parts of Haematococcus pluvialis powder, 50-60 parts of pumpkin powder, 30-40 parts of bitter gourd freeze-dried powder, 20-30 parts of Isomaltitol, 30-40 parts of whole wheat flour, 20-30 parts of Ashitaba freeze-dried powder, 2-4 parts of pollen pini, 1-2 parts of Chinese caterpillar fungus mycelium powder and 1-3 parts of nutrition additives. The health protein powder disclosed by the invention has abundant nutrients and can achieve the health care effects of reducing blood sugar, resisting fatigue and preventing diabetic complications if taken for a long time.

Owner:安徽珠峰生物科技有限公司

Healthcare agent for pet puppies

InactiveCN105230987AMake up for nutritional imbalancesIncrease nutritionAnimal feeding stuffBiotechnologyVitamin C

The invention discloses a healthcare agent for pet puppies. The healthcare agent for pet puppies comprises the following ingredients in parts by mass: 5-10 parts of egg micro-capsule powder, 5-15 parts of hydrolyzed wheat protein, 0.5-1.5 parts of vitamin A, 3-10 parts of glucose, 2-5 parts of chicken liver powder, 0.3-1 part of vitamin D3, 15-25 parts of puffed oat flour, 15-25 parts of puffed corn flour, 5-8 parts of vitamin C and 30-50 parts of skimmed milk powder. The healthcare agent for pet puppies of the invention is capable of supplementing nutrients required puppy growth and development, increasing pet appetite, reinforcing body immunity, preventing and treating intestinal inflammation, improving pet physique as well as improving hair quality. The healthcare agent for pet puppies is obvious in effect, safe and free of toxic and side effects.

Owner:山东贝瑞康生物科技有限公司

Method of treating or preventing obeisity and lipid metabolism disorders and compositions for use therein

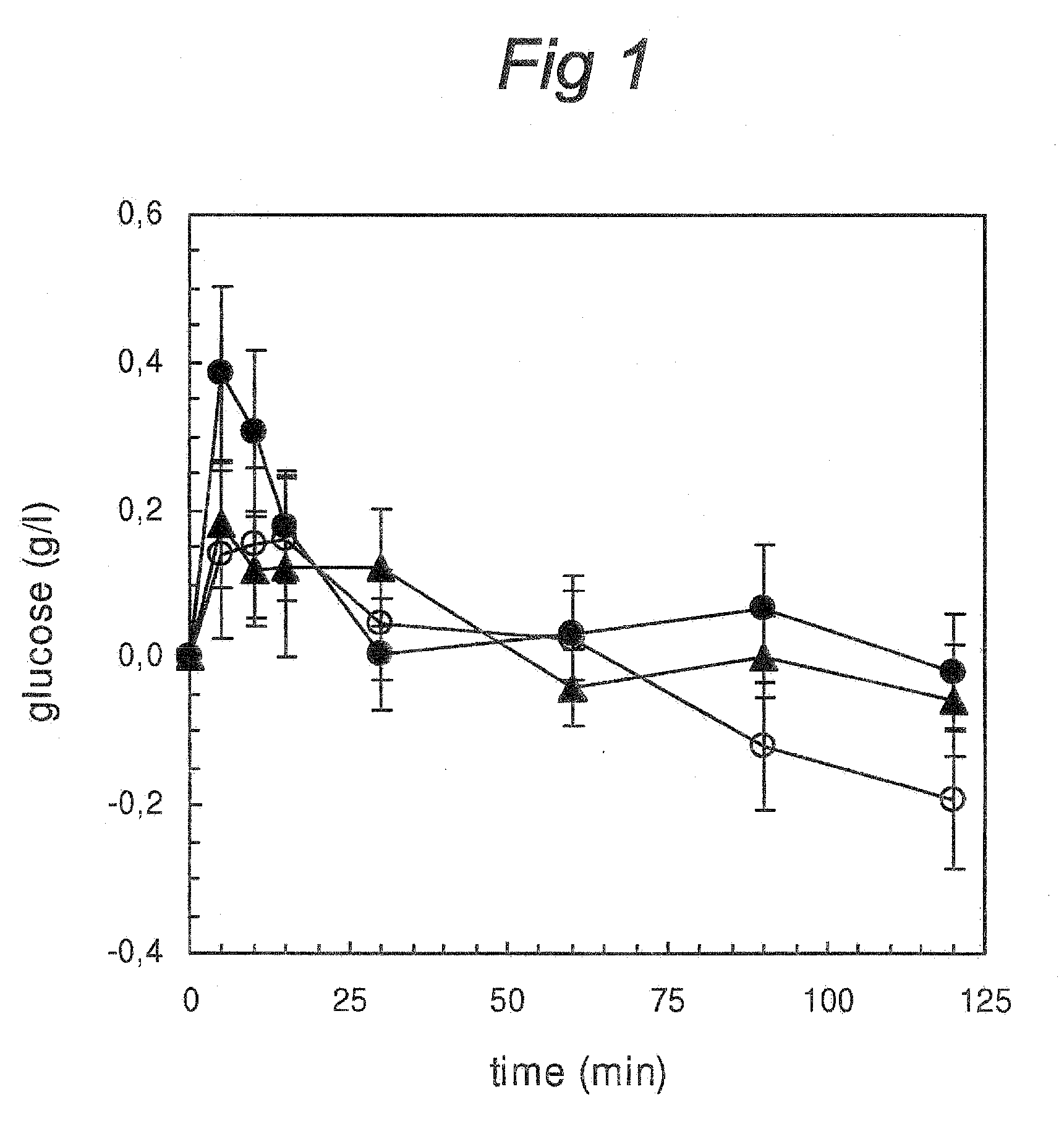

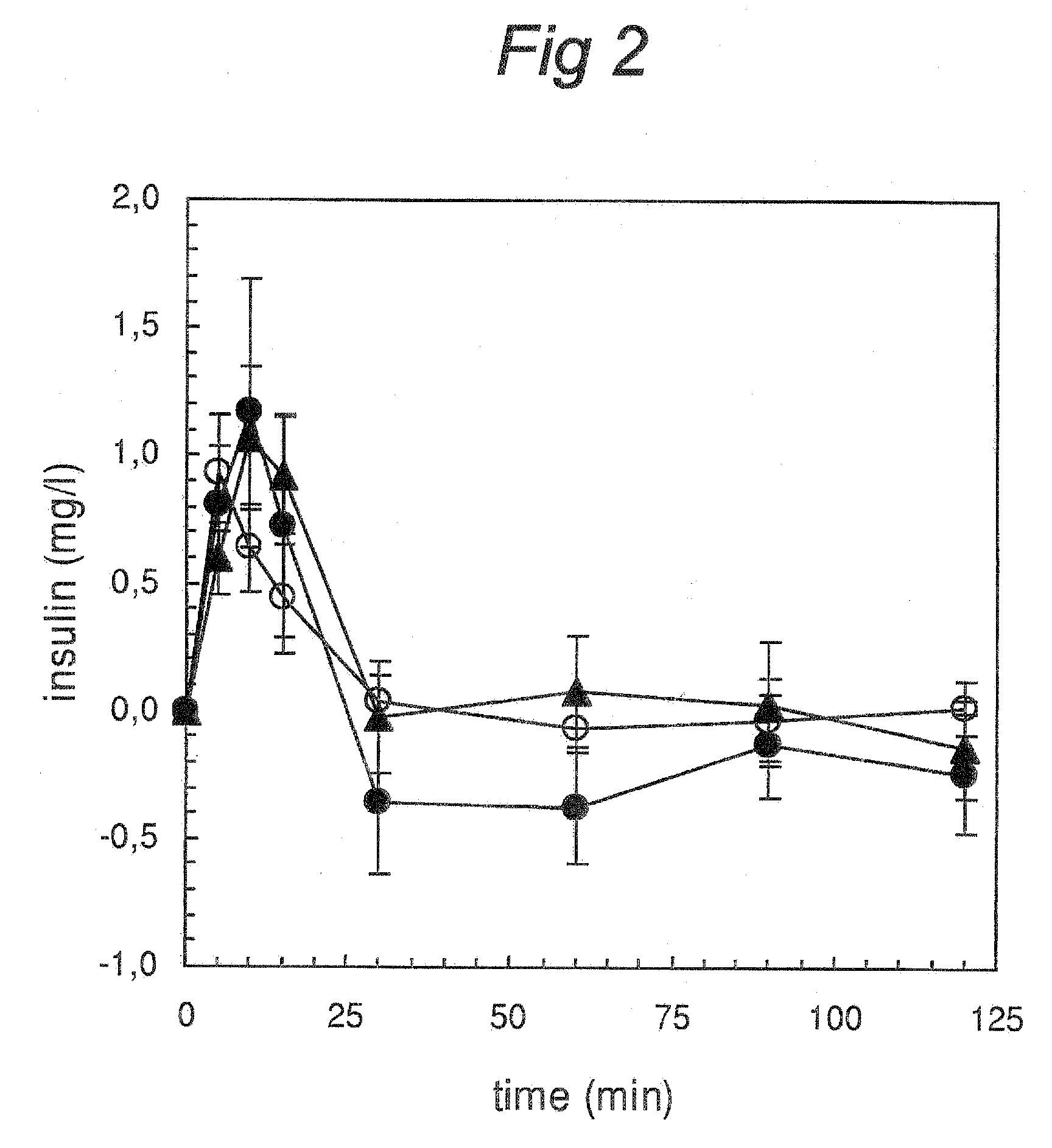

InactiveUS20060105938A1Lose weightUndesired impactBiocideHydrolysed protein ingredientsComplete proteinIntact protein

The present invention provides a method of preventing or treating human obesity, said method comprising ingesting a composition containing, calculated on dry matter: 10-100 wt. % protein hydrolysate; 0-90 wt. % intact protein; 0-50 wt. % carbohydrate; and wherein hydrolysed protein and intact protein together are present in a concentration (w / w) that exceeds the carbohydrate concentration (w / w). The invention also encompasses the use of the same composition in a method of preventing or treating lipid metabolism disorders and in a method for improving body appearance. Other aspects of the invention relate to nutritional beverages, snacks and soups that can advantageously be employed in accordance with the aforementioned methods.

Owner:KERRY GROUP SERVICES

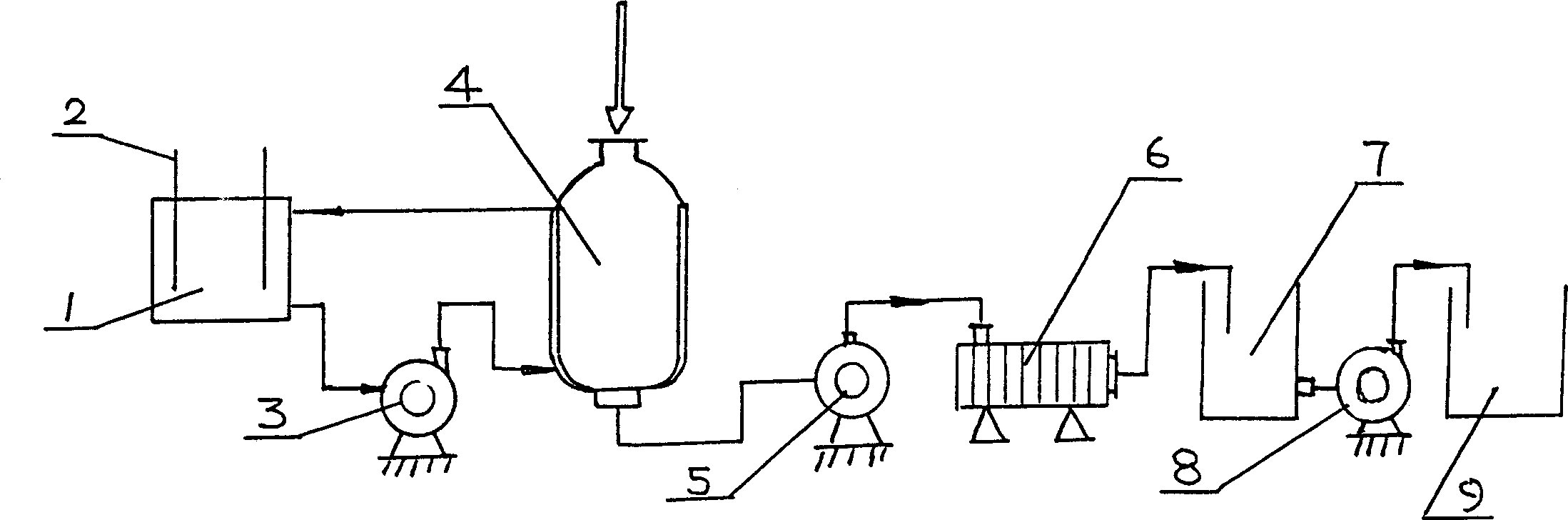

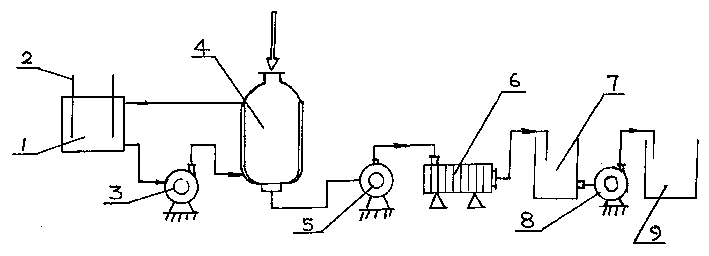

Coproduction process of pig brain protein hydrolysate and monosialoganglioside

ActiveCN102093440ARealize joint productionImprove utilizationNervous disorderHydrolysed protein ingredientsUltrafiltrationFreeze-drying

The invention discloses a method for obtaining pig brain protein hydrolysate and monosialoganglioside (GM1) from fresh pig brain through fractional extraction. The main process routes are as follows: (1) firstly, adding polar organic solvent homogenate fresh pig brain, and respectively collecting a filter cake and filtrate after filtration; (2) adding a certain amount of low-pole organic solvent and purified water in the filtrate from the step (1) for Folch lamination, then respectively carrying out resin column chromatography, hydrolysis and silicagel column chromatography so as to obtain high pure monosialoganglioside; and (3) adding a certain amount of acetone in the filter cake from the step (1) for degrease, filtering and drying, adding salt buffer solution and hydrolase for hydrolysis, and carrying out inacitivation, ultrafiltration purification, ultrafiltration concentration and vacuum freeze drying so as to obtain medical injection-stage pig brain protein hydrolysate.

Owner:SHANDONG NEWTIME PHARMA

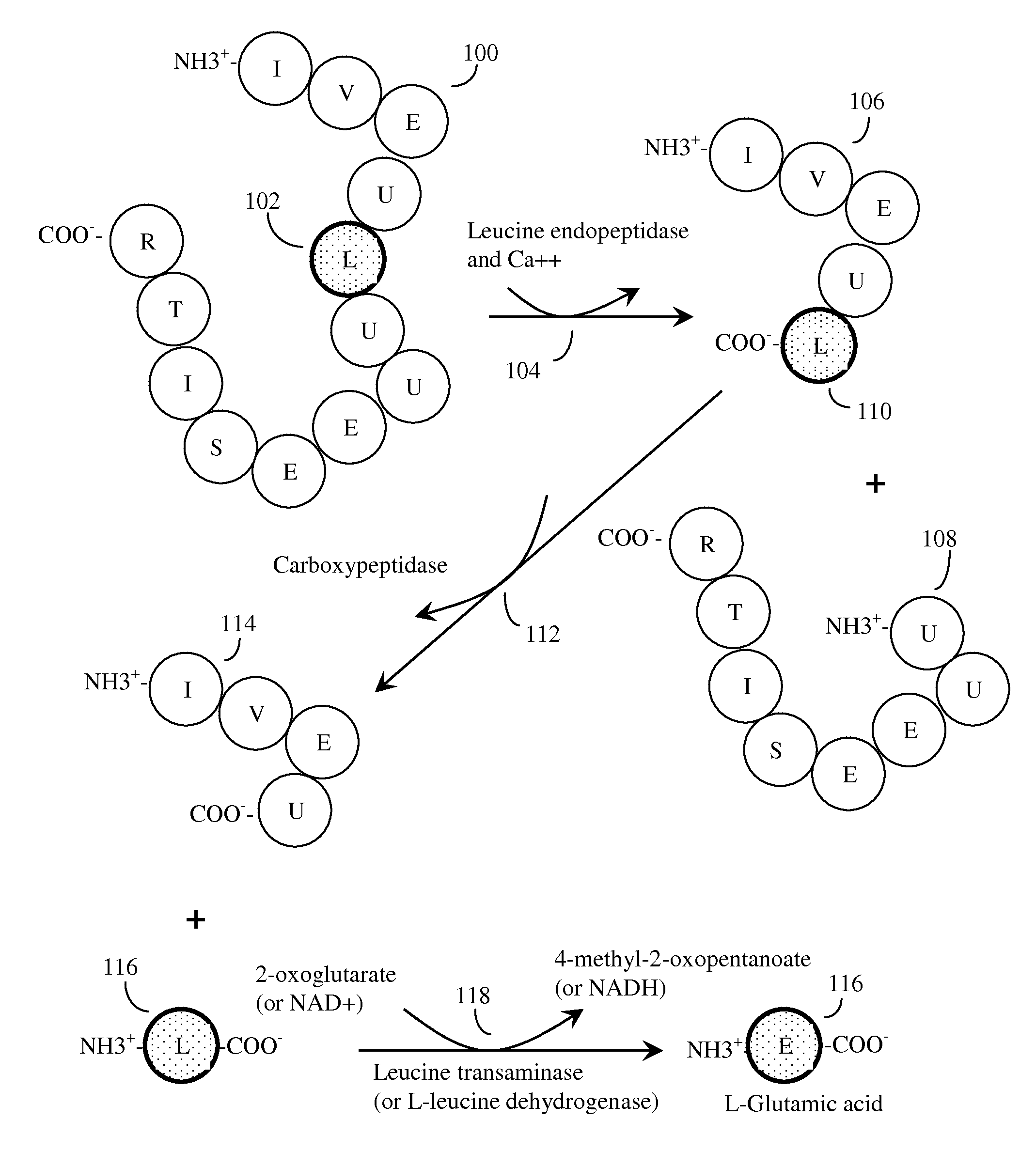

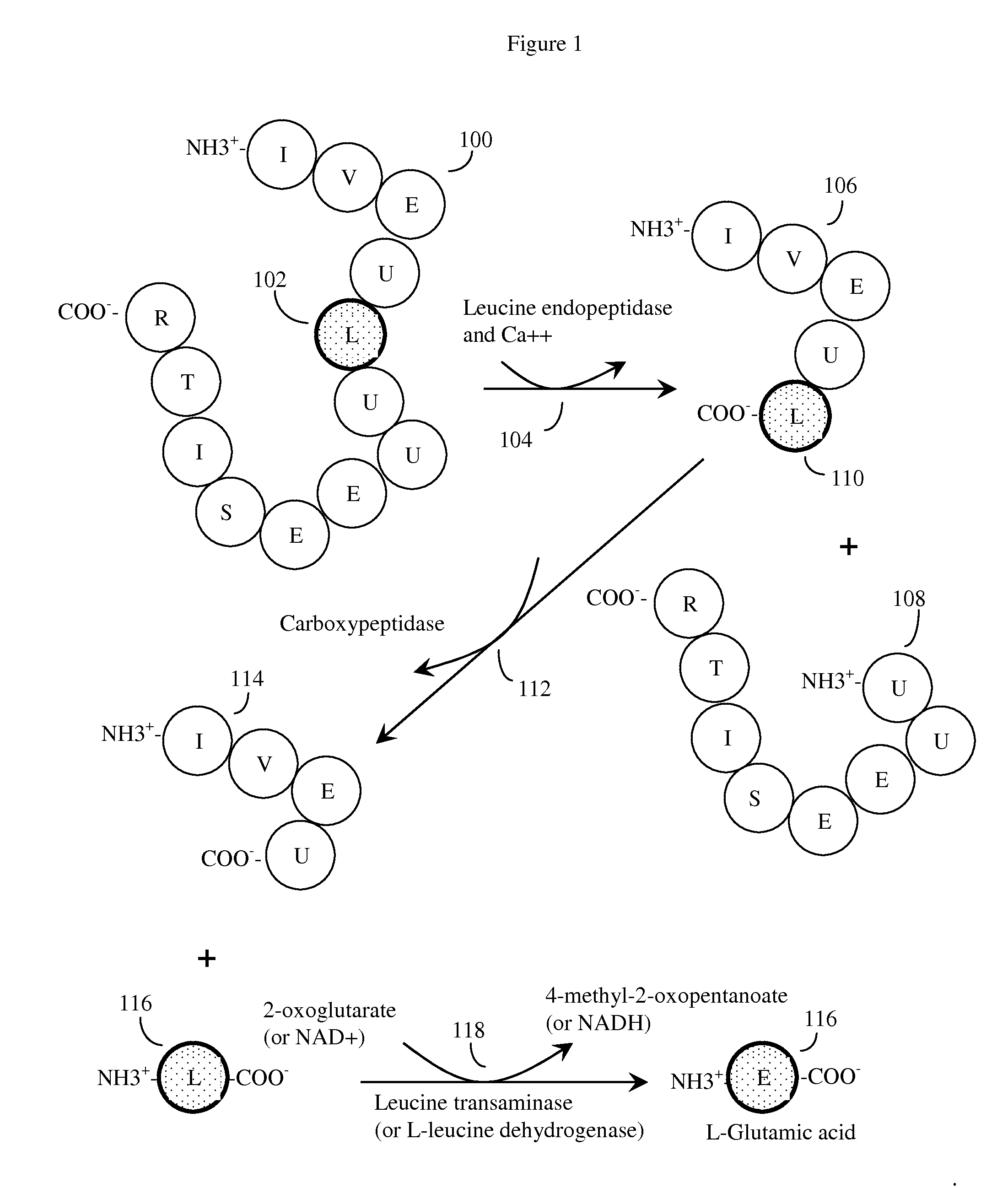

mTOR PATHWAY OPTIMIZED NUTRITIONAL COMPOSITIONS

ActiveUS20120082760A1Avoid stimulationLow costMilk preparationFood preparationBiotechnologyProtein materials

Method of reducing the mTOR pathway stimulating activity of amino acid containing nutritional materials. This method comprises treating an enzymatically hydrolysed protein material such as casein, whey, or soy protein with at least one enzyme capable of converting mTOR pathway stimulating amino acids and amino acid residues, such as leucine or methionine, into alternate chemical entities that do not stimulate or stimulate to a significantly lesser degree the mTOR pathway, while preserving the non-mTOR stimulating amino acids. These one or more alternate chemical entities should ideally be suitable for consumption, or alternatively be capable of being removed from the treated material through low cost extraction or conversion techniques. The material may then be sold as is, or alternatively packaged with low glycemic carbohydrates, healthy lipids, vitamins, and flavors and sold as a variety of different food products intended for an artificial diet intended to mimic the effects of caloric restriction.

Owner:ROSEDALE RONALD E

Health care agent for old dogs

InactiveCN105410347AEnhance digestion and absorptionReduce pleat spacingAnimal feeding stuffAccessory food factorsBiotechnologyDisease

The invention discloses a health-care agent for old dogs. The health care agent for old dogs consists of the following components in parts by weight: 5-10 parts of egg microcapsule powder, 0.3-1 part of a yucca extract, 5-15 parts of wheat hydrolyzed protein, 0.5-1.5 parts of astragalus membranaceus polysaccharide, 1-2 parts of probiotics, 15-25 parts of puffing oat flour, 10-20 parts of puffing corn flour, 0.5-1.5 parts of vitamin C, 30-40 parts of nonfat dry milk powder, 2-5 parts of chicken liver powder, 3-5 parts of glucose, 2-4 parts of xylooligosaccharide and 3-5 parts of sodium butyrate. According to the health care products disclosed by the invention, the digestion function of intestinal tracts of the old dogs can be improved, the utilization of nutrient substances can be improved, diseases of intestinal tracts can be prevented and treated, the immunity of organisms can be enhanced, and halitosis and the fetor of excrement can be reduced; the health care products are notable in effects, safe and free from toxic and side effects.

Owner:山东贝瑞康生物科技有限公司

Preparation method of amino acid foliage fertilizer

InactiveCN1460663ALow costLow priceNitrogenous fertilisersVegetable proteins working-upMonosodium glutamateOrganic fertilizer

The present invention relates to a method for preparing amino acid foliage fertilizer by utilizing polypeptide, amino acids and its intermediate product mixed solution obtained by hydrolyzing cheap protein resource-discarded material resulted from production of monosodium glutamate as raw material. Said invention adopts two production processes; first is enzymolysis, i.e. adopts proteinase hydrolysis and second process is acidolysis; using sulfuric acid or hydrochloric acid as catalyst, under the condition of a certain temp. hydrolyzing somatic protien. Said two processes can obtain the invented amino acid organic fertilizer.

Owner:何孝金

Method for producing hydrolyzed brain protein powder and cephalin by grease removal of supercritical carbon dioxide

InactiveCN102771620APhosphatide foodstuff compositionsAnimal proteins working-upBiotechnologyAnimal brain

The invention discloses a creative method for commercially producing hydrolyzed brain protein powder and cephalin by animal brains. The method comprises the steps of using supercritical carbon dioxide to remove grease, performing enzymolysis and using active carbon to decolorize; using macroporous resin to adsorb impurities, flowing out brain protein hydrolysate; using cation-anion resin to desalt; using the thin film to condensate the product, performing spray drying; obtaining hydrolysated brain protein powder and purifying the paste in a separation kettle I. The method overcomes the problem that the method for removing grease by the organic solvent produces residual solvent to cause the toxic reaction, removes grease cleanly, is easy to hydrolyze and filter, and strengthens fishy smell-removing and decolorizing ability of the active carbon due to macroporous resin; the creativity is as follows: the obtained hydrolysated brain protein powder is pink-white, has no odor and toxicity, and has high cephalin; two products can be produced at the same time, which can be applied in nutritious foods, health care products and foods, and can be manufactured drugs after being purified further.

Owner:LINGAO ZESHITAI BIOTECH CO LTD

Ginseng candy and production method thereof

InactiveCN103564125AImprove fatigueTo promote metabolismConfectionerySweetmeatsSide effectCynomorium songaricum

The invention discloses a ginseng candy, which is prepared from the following components in parts by weight: 25-30 parts of cynomorium songaricum, 10-20 parts of ginsenoside, 5-10 parts of protein hydrolysate, 1-5 parts of enzyme, and 60-75 parts of malt. According to the ginseng candy, pure natural healthy foods are adopted as raw materials, the ginseng candy does not have toxic or side effect, can be used for supplying cell nutrition, inhibiting free radicals, improving body fatigue and accelerating blood circulation, and make people energetic. The ginseng candy has the characteristics of good anti-fatigue effect, quick response, no drug tolerance and wide applicable people.

Owner:毛清奎

Method for manufacturing low-salt hydrolyzed vegetable protein

ActiveCN102550798AImprove amino acid conversion rateImprove conversion rateVegetable proteins working-upFlavorSolubility

The invention discloses a method for manufacturing low-salt hydrolyzed vegetable protein. The method comprises the following steps of: mechanically crushing a vegetable protein raw material to 20-100 meshes, and mixing with water; controlling the temperature to be between 55 and 85 DEG C for 10 to 60 minutes, heating to a temperature of between 95 and 120 DEG C for 10 to 120 minutes; adding neutral protease and flavored enzyme to be cultured for 8 to 24 hours; adding papain to be hydrolyzed for 50 to 120 hours; centrifuging to obtain supernatant; and drying the supernatant to prepare the hydrolyzed vegetable protein. According to the method, the hydrolyzed vegetable protein with low salt content, high transformation rate, no bitter taste, good solubility, and excellent flavor and taste can be extracted efficiently in a short time.

Owner:保定味群食品科技股份有限公司

Method for extracting protein and chitosan from head and shell of shrimp by lactobacillus acidophilus

ActiveCN102119759AAvoid pollutionLow costProtein composition from fishMicroorganism based processesBiotechnologyCALCIUM LACTOBIONATE

The invention discloses a method for extracting protein and chitosan from a head and a shell of a shrimp by lactobacillus acidophilus. The lactobacillus acidophilus SW01 is preserved by China center for type culture collection (CCTCC) and has the preservation number (CCTCC NO) of M2011035. The lactobacillus acidophilus SW01 can be used for simultaneously extracting the protein and the chitosan from the head and the shell of the shrimp, and the obtained hydrolyzed protein is rich in calcium lactate and other mineral substances. The method is simple in operation, and the production cost and the environmental pollution are reduced, so that the head and the shell of the shrimp can be fully utilized.

Owner:SOUTH CHINA AGRI UNIV

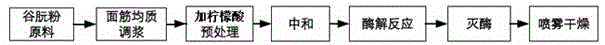

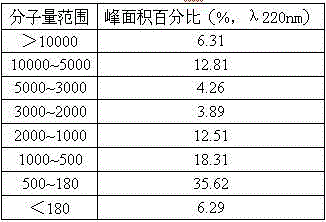

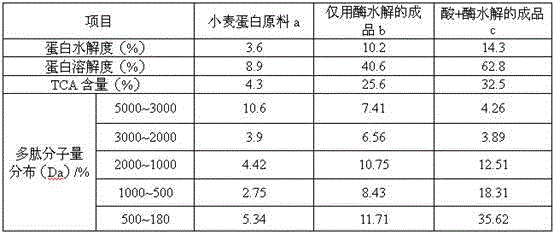

Preparation method of wheat protolysate

InactiveCN104605137APromote digestionImprove solubilityAnimal feeding stuffVegetable proteins working-upBiotechnologyEnzyme digestion

The invention discloses a preparation method of wheat protolysate, belonging to the technical field of food processing. The preparation method comprises the following steps: by taking wheat protein as a raw material, mixing slurry, pretreating, neutralizing, adding complex enzyme for enzymatic hydrolysis reaction and deactivating enzyme and spray-drying to obtain a product wheat protolystate. Citric acid is adopted to pretreat wheat protein to have deamidation, the solubility of the wheat protein can be increased, the subsequent protease is favorably close to an enzyme digestion site, the enzyme utilization rate, solubility and enzymolysis speed can be increased. The wheat protolysate prepared by adopting the method is good in solubility, dispensing with obvious bitter taste, the content of small peptide is high, the protein is high digestion rate and easy to absorb, the bioavailability of the wheat protein can be greatly improved; and the preparation technology is simple, the time consumption is short, enzyme investment cost is low, and the preparation method is suitable for industrial production.

Owner:江苏康科食品工程技术有限公司

Method of preparing sodium levofolinate and applications thereof on preparing tumour-curing medicines

InactiveCN101229167AAvoid cloggingEffectiveOrganic active ingredientsOrganic chemistryDissolutionDextran

The invention provides a preparation method of medical left folinic acid sodium and an application in preparation of tumor treatment medicine, relating to a preparation method of the medical left folinic acid sodium in tumor treatment medicine preparation. Two preparation methods of the medical left folinic acid sodium are that: firstly, the left folinic acid sodium of prescription dosage are weighed, water for injection is added to prepare a suspension solution, sodium hydroxide solution (or sodium carbonate, sodium bicarbonate solution) is added, the suspension solution is stirred for total dissolution, and then at least one supplement containing mannitol, dextran, glucose, sodium chloride or protein hydrolysate is added; the injecting agents comprise the dried powder injection and the directly prepared liquid formulation. Secondly, the left folinic acid sodium of prescription dosage are weighed, water for injection is added, and at least one supplement containing mannitol, dextran, glucose, sodium chloride or protein hydrolysate are added and stirred for total dissolution to prepare the solution; the injecting agents comprise the dried powder and the directly prepared liquid formulation. The left folinic acid sodium is applied in preparing medicine of tumor treatment.

Owner:齐建新

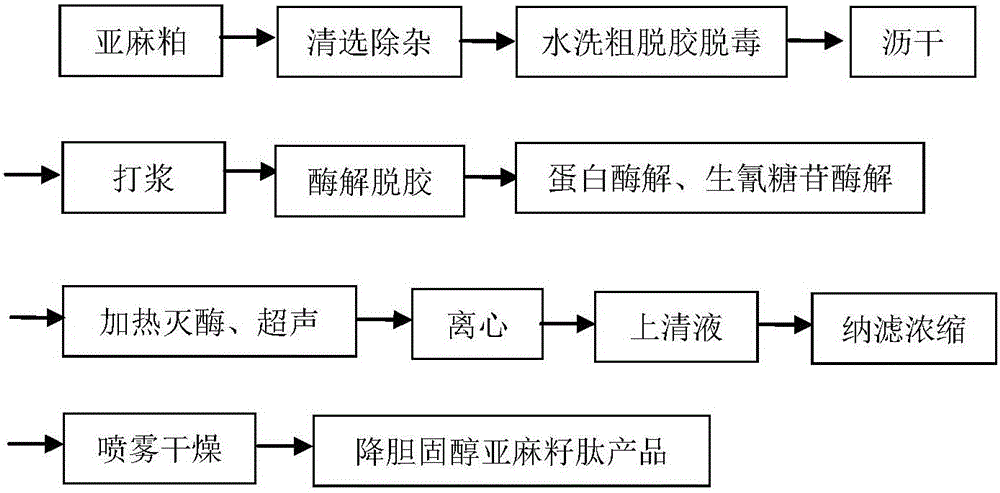

Flaxseed peptides having effects of lowering cholesterol and preparation method thereof

ActiveCN105918610AReduce lossesHas cholesterol-lowering physiological activityProtein composition from vegetable seedsProtein foodstuffs working-upNeutral proteaseDecomposition

The present invention discloses flaxseed peptides having effects of lowering cholesterol and a preparation method thereof. The preparation method includes the following steps: flaxseed selecting and impurity removing, primary low-temperature and weak-acid water washing, primary beating, primary pectin lyase enzymatic digesting and degumming, primary papain, neutral protease, beta-glucosidase, alpha-cyanohydrin protein and hydroxynitrile lyases protein hydrolysate and cyanogenic glycoside decomposition reacting, ultrasonic high-temperature enzyme inactivating and detoxifying, and then centrifuging, nano-filtering, spray-drying, and cholesterol-lowering flaxseed peptide obtaining. The preparation method solves the effects of the flaxseed gum on the flaxseed proteolysis and removes cyanogenic glycosides and hydrocyanic acids in the products of the flaxseed peptides. The flaxseed peptide products are prepared for the first time, can be applied in the food and health-care food industries, and have broad business outlooks.

Owner:瑞泰高直生物科技(武汉)有限公司

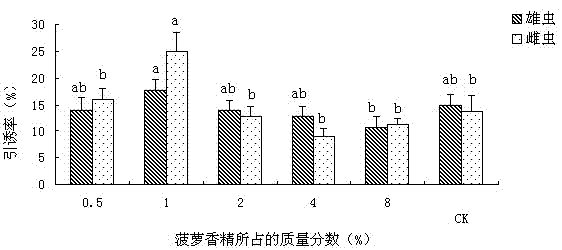

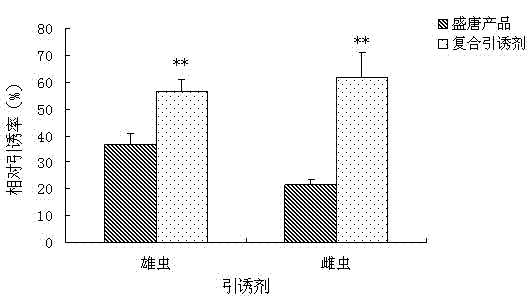

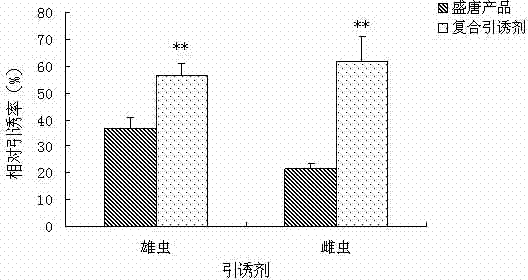

Composite attractant of bactrocera dorsalis hendel

InactiveCN102499269ASimple recipeRaw materials are cheap and easy to getBiocidePest attractantsBiotechnologyHydrolysate

The invention discloses a composite attractant of bactrocera dorsalis hendel, which comprises aqueous solution of a molasses, aqueous solution of a complex protein hydrolyzate and a fruit flavor. The mass ratio of the aqueous solution of the molasses to the aqueous solution of the complex protein hydrolyzate is 4:1; the complex protein hydrolyzate is the hydrolysate which is obtained by mixing soy protein and brewer's yeast protein at the weight ratio of 1:1-9, adding 5,000U / g of acidic protease, 0.5-5.0 parts by weight of preservative and 0.01-0.1 part by weight of spinosad, and hydrolyzing at 50 DEG C for 2hours. The formula of the composite attractant of the bactrocera dorsalis hendel is simple, and the raw materials are cheap and easy to obtain. The composite attractant has good effect of attracting the male and female adult bactrocera dorsalis hendel, and particularly, the composite attractant can attract more than 25% of bactrocera dorsalis hendel of 10-11 days old. The raw materials used for preparing the composite attractant do not contain any harmful chemical substances, have no toxic effects on people and animals and meet the environmental protection requirements.

Owner:SOUTH CHINA AGRI UNIV

Smallpeptide chelate trace element feed additive and production process thereof

InactiveCN102657285AAvoid pollutionMaximize added valueAnimal feeding stuffTrace elementProtein hydrolysates

A smallpeptide chelate trace element feed additive comprises, in mass percent, from 18 to 89% of smallpeptide protein, from 10 to 20% of salt and from 0.59 to 62% of inorganic trace element when in a dry state. A production process includes following steps of (1) concentrating protein hydrolysate waste liquor which has the solid content of 5-15% and is generated from production of chondroitin and heparin sodium into protein hydrolysate waste liquor with the solid content of 30-40%; (2) adding prepared single monomial or compounded inorganic trace element solution with the mass percent concentration of 15-35%, controlling a pH (potential of hydrogen) value to be 6-8, and performing chelation reaction; and (3) performing spraying drying at the temperature ranging from 180 DEG C to 220 DEG C. The smallpeptide chelate trace element feed additive and the production process thereof effectively avoid waste liquor pollution generated in a production process of the chondroitin and heparin sodium, and turn waste into wealth, and prepared organic chelate feed additive enables the additional value of the waste liquor to be maximized. Spraying drying technology is adopted for the production process, and the problem that drying time is long and products are easy to be polluted by bacteria in a common method is solved.

Owner:张军民

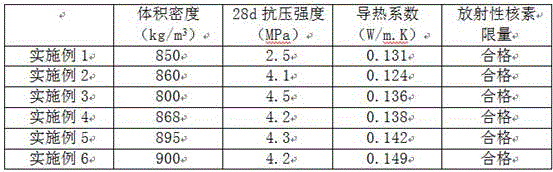

Lightweight concrete

The invention relates to the technical field of concrete, in particular to lightweight concrete.The lightweight concrete is prepared from 32-48 parts of cement, 6-8 parts of natural gypsum, 4-8 parts of oil shale ash, 1.2-4.8 parts of EPS particles, 5-10 parts of ceramic particles, 8-15 parts of pumice stone, 2.4-6.2 parts of hydrolyzed protein, 1.8-5.4 parts of Arabic gum, 5-10 parts of expanded perlite fine aggregate, 3.6-5.8 parts of phosphorus gypsum, 6-10 parts of glass fibers, 8-12 parts of an acrylic acid organic thickening agent, 1.2-5 parts of a water reducing agent, 1.8-4.8 parts of a rare earth stabilizing agent, 1.2-3.6 parts of a coagulation agent and 2.4-5.6 parts of an early-strength agent.The lightweight concrete is light in weight and convenient to construct, meanwhile has good heat-preserving performance and is low in cost; the heat resistance degree is high; heat resistance of a cement inorganic material can reach 500 DEG C or above, no thermal decomposition exists, and therefore service life is longer, and it is avoided that heat preservation loses efficacy; the lightweight concrete is environmentally friendly and free of toxin and harm; using cost is lower, and construction speed is high.

Owner:陈翔

Composition, process for making using pressurized fluid, and uses thereof

InactiveUS20050170023A1Cosmetic propertyGood conditioning effectCosmetic preparationsBiocideHydrolysed proteinAmino acid

A process for preparing a composition by percolating a fluid containing steam, at a pressure of at least 3 bar, through at least one member selected from an amino acid, oligopeptide, peptide, optionally modified, optionally hydrolysed protein, and mixtures thereof, in solid or pasty form.

Owner:LOREAL SA

Preparation method for flat almond oligosaccharide and instant protein hydrolysate powder

InactiveCN102747119AImprove efficiencyLarge specific surface areaFermentationPectinaseNeutral protease

The invention provides a preparation method for flat almond oligosaccharide and instant protein hydrolysate powder. The method comprises the following steps: carrying out superfine grinding on degreased flat almond powder, then dispersing the ground flat almond powder in deionized water, adjusting a pH value, adding cellulose and carrying out an enzymolysis reaction; adjusting a pH value, adding pectase, carrying out an enzymolysis reaction, then carrying out enzyme deactivation and filtration with a microfiltration membrane so as to obtain retentate and filtrate, standing the retentate for subsequent usage, and subjecting the filtrate to ultrafiltration and condensation and to spray drying with an atomizer so as to obtain flat almond oligosaccharide; and dispersing the retentate in deionized water, adjusting the pH value of an obtained solution, adding alkaline protease and flavorzyme, carrying out an enzymolysis reaction, adjusting a pH value, adding neutral protease, carrying out an enzymolysis reaction, then carrying out enzyme deactivation and filtration with the microfiltration membrane and subjecting obtained filtrate to ultrafiltration and condensation and to spray drying with the atomizer so as to obtain flat almond protein hydrolysate powder. The method provided in the invention is advantaged in that the advantages of a simple process, low energy consumption and low production cost are obtained, the prepared flat almond protein hydrolysate powder has high protein content and good water solubility and the method is suitable for industrial production.

Owner:BOHAI UNIV

Fish-meat-flavored liquid seasoning as well as preparation method and use of fish-meat-flavored liquid seasoning

InactiveCN107788491AFeatures outstanding fragranceIncrease profitFood scienceMonosodium glutamateMaillard reaction

The invention discloses fish-meat-flavored liquid seasoning as well as a preparation method and use of the fish-meat-flavored liquid seasoning. The preparation method mainly comprises the following steps of sequentially adding fish meat zymolyte, chicken meat zymolyte, xylose, glucose, cysteine, glycine, leucine, spice, plant hydrolyzed protein, a yeast extract, table salt, monosodium glutamate, modified starch, xanthan gum and pure water in a reaction kettle, performing uniform stirring and mixing, performing reaction under the temperature of 95-105 DEG C for 55-75 minutes, and performing continuous stirring in the reaction process; after cooling, adding potassium sorbate and trisodium phosphate dissolving in a little water, performing uniform stirring and performing filling so as to obtain the fish-meat-flavored liquid seasoning. An enzymolysis technology and a Maillard reaction are used, so that fish protein is subjected to enzymolysis to obtain polypeptide and amino acids, and thefish meat is not prominent in freshness and fragrance; and besides, spice is added in an appropriate compounding ratio, so that effective components of the spice dissolve in the seasoning, the utilization rate of the spice is increased, and the effects of the spice can be sufficiently exerted.

Owner:LIAOCHENG XINHENGJI BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com