Preparation method for flat almond oligosaccharide and instant protein hydrolysate powder

A technology for hydrolyzing protein powder and oligosaccharides, which is applied in the field of preparation of almond oligosaccharides and instant hydrolyzed protein powder, which can solve the problems of no relevant reports, high energy consumption in equipment operation, complicated process, etc., and avoid high-temperature concentration process , low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Smash

[0036] 30g of defatted flat almond powder is superfinely pulverized to pass through a 200-mesh sieve;

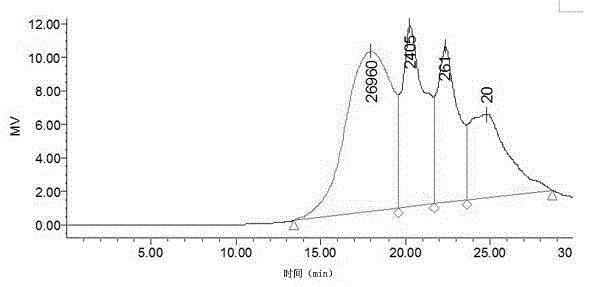

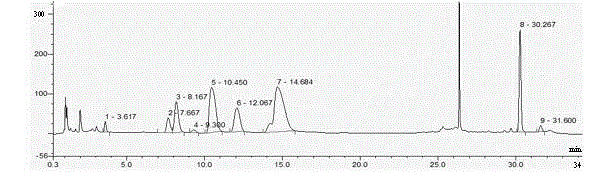

[0037] 2) Preparation of almond oligosaccharides by enzymatic hydrolysis

[0038] Disperse 30g of crushed flat almond powder in 1L of deionized water, adjust the pH to 3.0 with hydrochloric acid, and add cellulase at 35°C according to the mass ratio of cellulase activity to flat almond powder at 100U / g. Then use hydrochloric acid to adjust the pH to 3.5. At 40°C, add pectinase according to the mass ratio of the enzyme activity of pectinase to flat almond powder at 200U / g. Enzyme for 20 minutes, filter with microfiltration membrane, get 35.6g of retentate and filtrate, retentate for later use, use polysulfone ultrafiltration membrane to concentrate filtrate to 25% of the original volume, membrane separation parameters: cross-flow velocity is 3cm / s, operating gauge pressure The temperature is 0.04MPa, the temperature is 25°C, and the centrifugal spray dryer...

Embodiment 2

[0052] 1) crush

[0053] 100g of defatted flat almond powder is superfinely pulverized to pass through a 200-mesh sieve;

[0054] 2) Preparation of almond oligosaccharides by enzymatic hydrolysis

[0055] Disperse 100g of crushed flat almond powder in 1L of deionized water, adjust the pH to 5.0 with hydrochloric acid, and add cellulase at 55°C according to the mass ratio of cellulase activity to flat almond powder at 1000U / g. hydrolysis reaction for 8 hours; then adjust the pH to 5.5 with hydrochloric acid, at 65°C, add pectinase according to the mass ratio of pectinase activity to flat almond powder at 800U / g, enzymolysis reaction for 8h, and extinguish at 95°C Enzyme for 30min, filter with microfiltration membrane, get 130.8g of retentate and filtrate, retentate for later use, use polysulfone ultrafiltration membrane to concentrate filtrate to 30% of the original volume, membrane separation parameters: cross-flow velocity is 4cm / s, operating gauge pressure The temperature ...

Embodiment 3

[0061] 1) crush

[0062] 50g of defatted flat almond powder is superfinely pulverized to pass through a 200-mesh sieve;

[0063] 2) Preparation of almond oligosaccharides by enzymatic hydrolysis

[0064] Disperse 50g of crushed flat almond powder in 1L of deionized water, adjust the pH to 4.0 with hydrochloric acid, and add cellulase at 40°C according to the mass ratio of cellulase activity to flat almond powder at 300U / g. Then use hydrochloric acid to adjust the pH to 4. At 50°C, add pectinase according to the mass ratio of the enzyme activity of pectinase to flat almond powder at 400U / g. Enzyme for 25 minutes, microfiltration membrane filtration, 62.9g of retentate and filtrate were obtained, the retentate was used for later use, and the filtrate was concentrated to 27% of the original volume by polysulfone ultrafiltration membrane. Membrane separation parameters: cross-flow velocity of 4cm / s, operating gauge pressure The temperature is 0.05MPa, the temperature is 28°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com