Flaxseed peptides having effects of lowering cholesterol and preparation method thereof

A technology for lowering cholesterol and flaxseed is applied in the field of food-derived protein deep processing, which can solve the problems of restricting the application of flaxseed meal, and achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

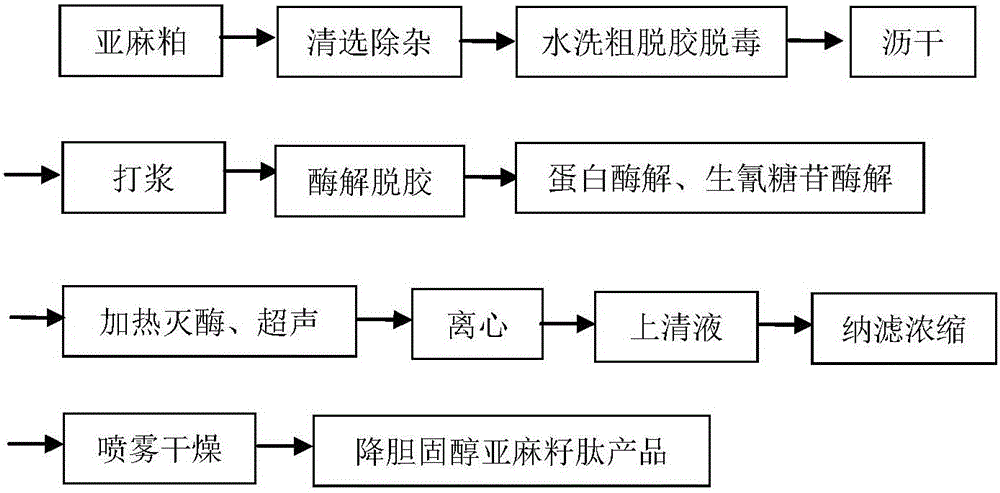

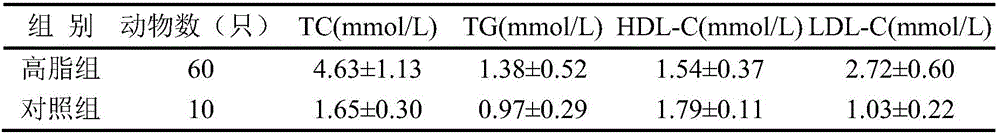

Method used

Image

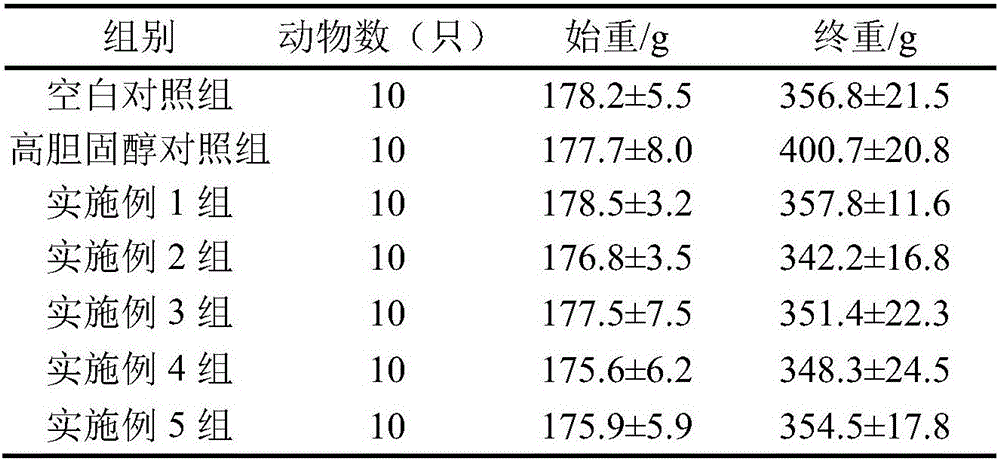

Examples

Embodiment 1

[0018] The preparation of embodiment 1 lowering cholesterol flaxseed peptide

[0019] After cleaning the flax meal to remove impurities, add a solution containing 0.1% citric acid and 0.1% glacial acetic acid according to the material-to-water ratio of 1:5 (w / v), wash with water at a controlled temperature of 20°C for 0.5h, drain and dry according to the ratio of material to liquid 1:10 (w / v) add water and beat. Adjust the pH of the beating solution to 8.0, add pectin lyase with a substrate concentration of 1%, and perform enzymatic hydrolysis at 30°C for 1 hour. After enzymatic hydrolysis and degumming, adjust the pH to 7.5, and sequentially add papain, 2% neutral protease, 1% β-glucosidase, and 1% α-hydroxyhydrinase at the substrate concentration for 2 hours. . Heat the enzymolysis solution to boiling and keep it for 1 hour, turn on the ultrasonic wave 5 minutes before the end of the enzyme inactivation, the frequency is 30KHZ and the ultrasonic wave is continuous for 5 mi...

Embodiment 2

[0020] The preparation of embodiment 2 lowering cholesterol flaxseed peptide

[0021] After cleaning the flax meal to remove impurities, add a solution containing 0.2% citric acid and 0.5% glacial acetic acid according to the material-to-water ratio of 1:20 (w / v), wash it with water at a controlled temperature of 25°C for 1.5 hours, drain it, and mix it according to the material-liquid ratio 1:20 (w / v) add water and beat. Adjust the pH of the beating solution to 9.5, add pectin lyase with a substrate concentration of 1.5%, and perform enzymatic hydrolysis at 32°C for 2 hours. After enzymatic hydrolysis and degumming, adjust the pH to 7.0, and add papain with substrate concentration of 2%, neutral protease with 2%, β-glucosidase with 1.5%, and α-hydroxyhydrinase with 1.5% for 3 hours. . Heat the enzymolysis solution to boiling and keep it for 2 hours, turn on the ultrasound 8 minutes before the end of the enzyme inactivation, the frequency is 40KHZ continuous ultrasound for 8...

Embodiment 3

[0022] Embodiment 3 Preparation of cholesterol-lowering flaxseed peptide

[0023] After cleaning the flax meal to remove impurities, add a solution containing 0.2% citric acid and 0.2% glacial acetic acid according to the material-to-water ratio of 1:10 (w / v), wash it with water at a controlled temperature of 40°C for 1 hour, drain it, and use a material-to-liquid ratio of 1 :12(w / v) add water and beat. Adjust the pH of the beating solution to 9.3, add pectin lyase with a substrate concentration of 0.8%, and perform enzymatic hydrolysis at 26°C for 2 hours. After enzymatic hydrolysis and degumming, adjust the pH to 6.5, and sequentially add papain, 1% neutral protease, 1% β-glucosidase, 1% α-hydroxyhydrinase with a substrate concentration of 1.5 h. Heat the enzymolysis solution to boiling and keep it for 0.5h, turn on the ultrasonic wave 3min before the end of the enzyme inactivation, the frequency is 25KHZ and the ultrasonic wave is continuous for 3min. After the enzyme in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com