A kind of darkened lignin and its application in the inner layer paper of the outer bag of the fruit breeding cover

A lignin and inner layer technology, applied in the field of papermaking, can solve the problems of large gaps and affecting the opacity of paper, and achieve the effect of low cost, low price, non-toxic, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

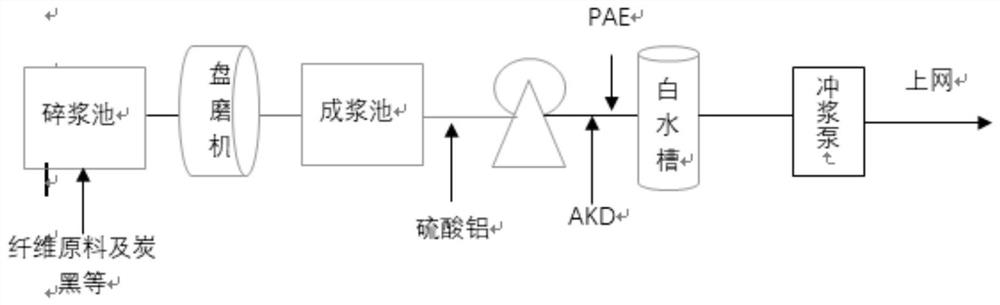

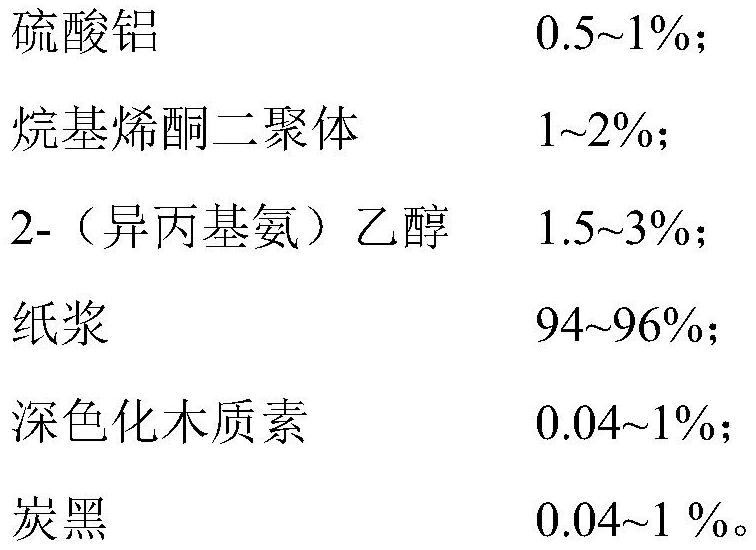

Method used

Image

Examples

Embodiment 1

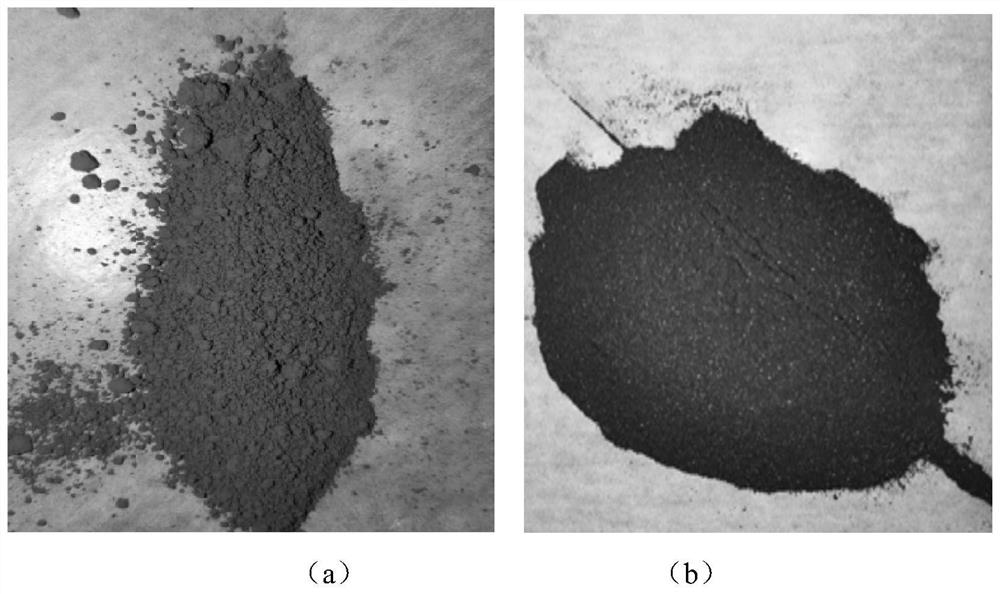

[0048]1), at room temperature, 150g alkali lignin ( figure 1 a) be dissolved in 3000mL pH and be in the sodium hydroxide solution of 13;

[0049] 2), stirring the alkali lignin solution obtained in step 1) at room temperature to fully dissolve it;

[0050] 3), add 30g ferric chloride in the alkali lignin solution obtained in step 2);

[0051] 4), the solution obtained in step 3) is subjected to solid-liquid separation;

[0052] 5), the solid obtained in step 4) is washed to neutrality, and dried, and the solid obtained is the darkened lignin ( figure 1 b).

Embodiment 2

[0054] 1), at room temperature, dissolve 150g of alkali lignin in 3000mL of sodium hydroxide solution whose pH is 13;

[0055] 2), stirring the alkali lignin solution obtained in step 1) at room temperature to fully dissolve it;

[0056] 3), add 50g ferric chloride in the alkali lignin solution obtained in step 2);

[0057] 4), the solution obtained in step 3) is subjected to solid-liquid separation;

[0058] 5), washing the solid obtained in step 4) to neutrality, and drying, and the obtained solid is darkened lignin.

Embodiment 3

[0060] 1), at room temperature, dissolve 150g of alkali lignin in 3000mL of sodium hydroxide solution whose pH is 13;

[0061] 2), stirring the alkali lignin solution obtained in step 1) at room temperature to fully dissolve it;

[0062] 3), add 15g ferric chloride in the alkali lignin solution obtained in step 2);

[0063] 4), the solution obtained in step 3) is subjected to solid-liquid separation;

[0064] 5), washing the solid obtained in step 4) to neutrality, and drying, and the obtained solid is darkened lignin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com