A preparation method of graphite phase carbon nitride nano bouquet with amorphous surface

A technology of graphite phase carbon nitride and amorphous state, which is applied in the direction of chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., to achieve the effect of simple and effective process, low price, non-toxicity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of graphite phase carbon nitride nano bouquet with amorphous surface, it comprises the following steps:

[0037](1) Weigh 1.26g melamine and 1.61g ammonium chloride according to the molar ratio of melamine and ammonium chloride 1:3;

[0038] (2) Grind the above-mentioned raw materials that have been weighed, ball mill them, mix them evenly at a high speed, put them into a 30ml reaction kettle, then put the sealed reaction kettle into a well-type crucible furnace, keep it warm at 450°C for 5 hours, Cool to room temperature, open the kettle and take out the crude product;

[0039] (3) Disperse the crude product in 50ml of distilled water, add 40ml of 12mol / L hydrochloric acid and 2ml of 15mol / L nitric acid, heat and stir at 80°C for 12h, then suction filter, wash with ethanol, and finally vacuum dry at 80°C for 24 hours , 1.94 g of black carbon nitride powder can be obtained with a yield of 95.2%.

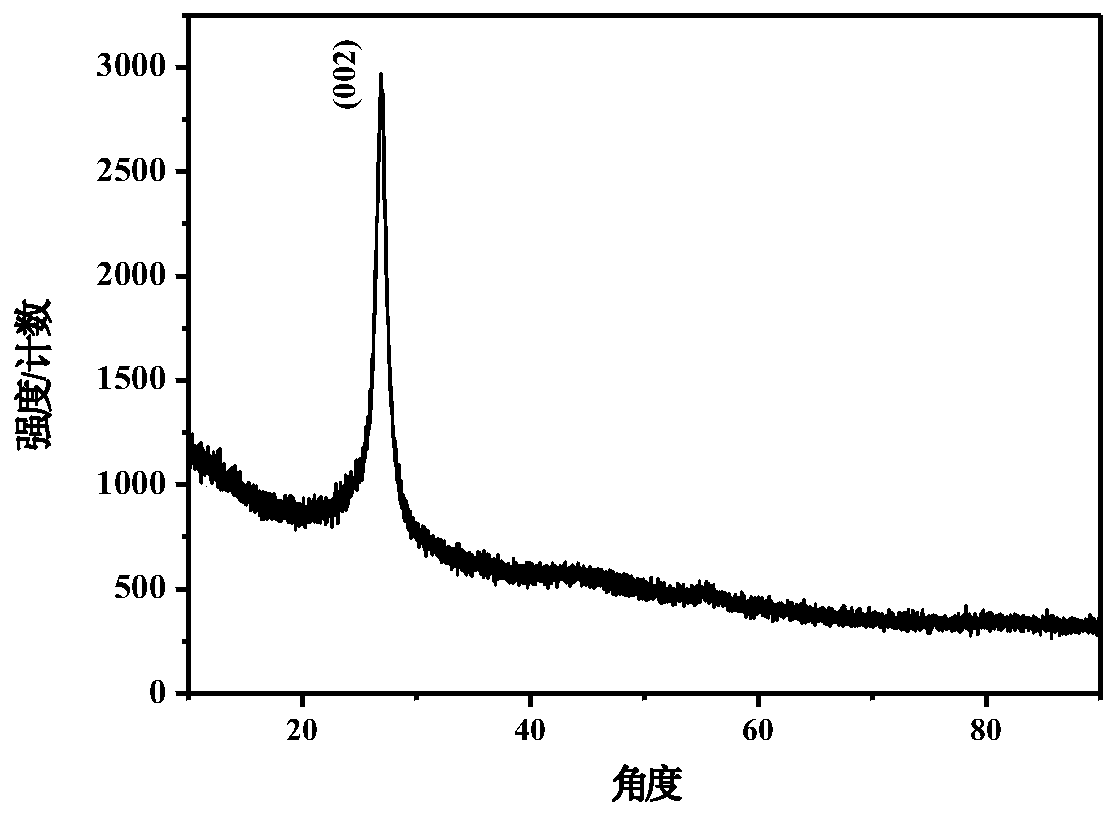

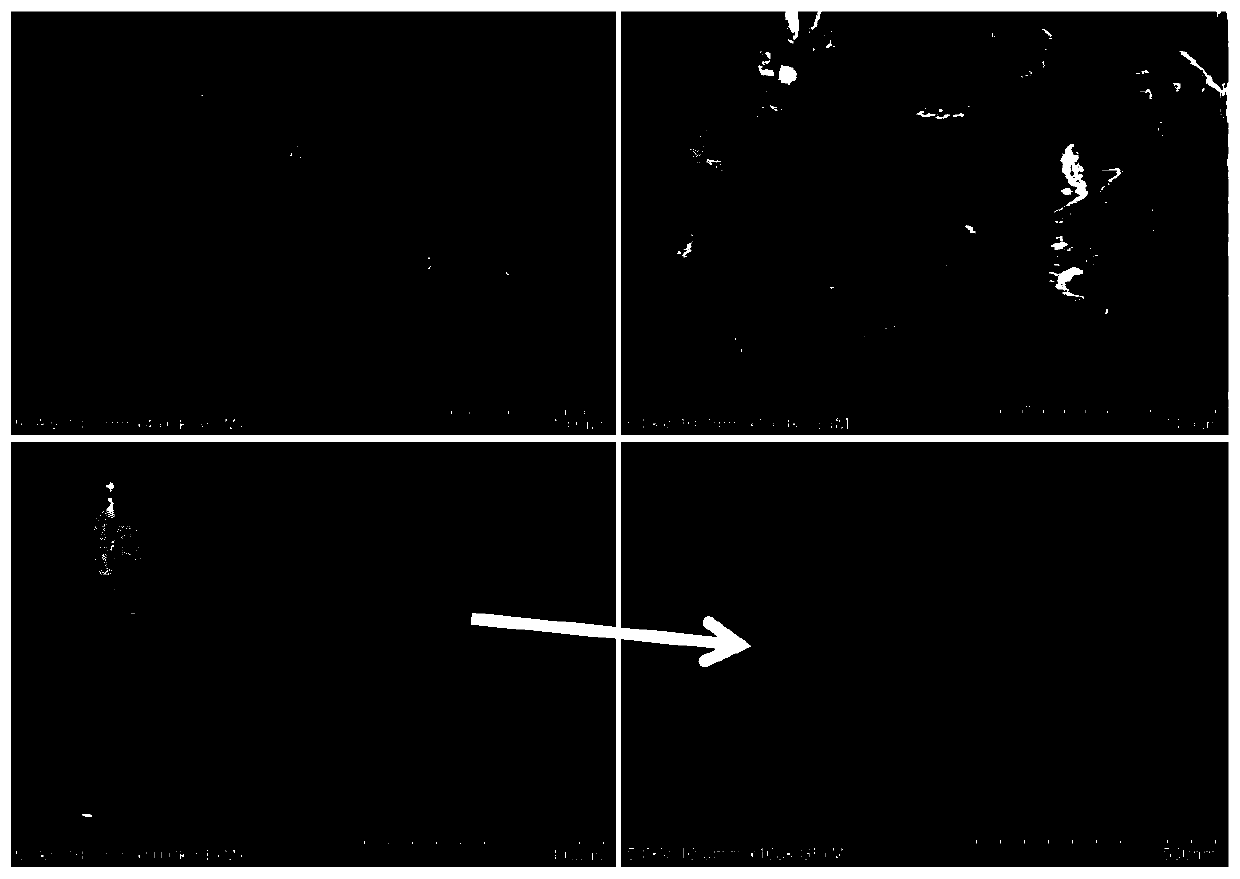

[0040] attached figure 1 The XRD spectrum of the ...

Embodiment 2

[0046] A preparation method of graphite phase carbon nitride nano bouquet with amorphous surface, it comprises the following steps:

[0047] (1) Take by weighing 1.02g melamine and 1.08g ammonium chloride according to the molar ratio of melamine and ammonium chloride 1:2.5;

[0048] (2) Grind the above-mentioned raw materials that have been weighed, ball mill them, mix them evenly at a high speed, put them into a 30ml reaction kettle, then put the sealed reaction kettle into a well-type crucible furnace, keep it warm at 450°C for 5 hours, Cool to room temperature, open the kettle and take out the crude product;

[0049] (3) Disperse the crude product in 50ml of distilled water, add 40ml of 12mol / L hydrochloric acid and 2ml of 15mol / L nitric acid, heat and stir at 50°C for 12h, then suction filter, wash with ethanol, and finally vacuum dry at 80°C for 24 hours , 1.88 g of black carbon nitride powder can be obtained with a yield of 81.4%.

[0050] The product is analyzed by XR...

Embodiment 3

[0052] A preparation method of graphite phase carbon nitride nano bouquet with amorphous surface, it comprises the following steps:

[0053] (1) Weigh 1.59g melamine and 1.35g ammonium chloride according to the molar ratio of melamine and ammonium chloride 1:2;

[0054] (2) Grind the above-mentioned raw materials that have been weighed, ball mill them, mix them evenly at a high speed, put them into a 30ml reaction kettle, then put the sealed reaction kettle into a well-type crucible furnace, keep it warm at 450°C for 5 hours, Cool to room temperature, open the kettle and take out the crude product;

[0055] (3) Disperse the crude product in 50ml of distilled water, add 40ml of 12mol / L hydrochloric acid and 2ml of 15mol / L nitric acid, heat and stir at 50°C for 12h, then suction filter, wash with ethanol, and finally vacuum dry at 80°C for 24 hours , 2.42 g of black carbon nitride powder can be obtained with a yield of 82.5%.

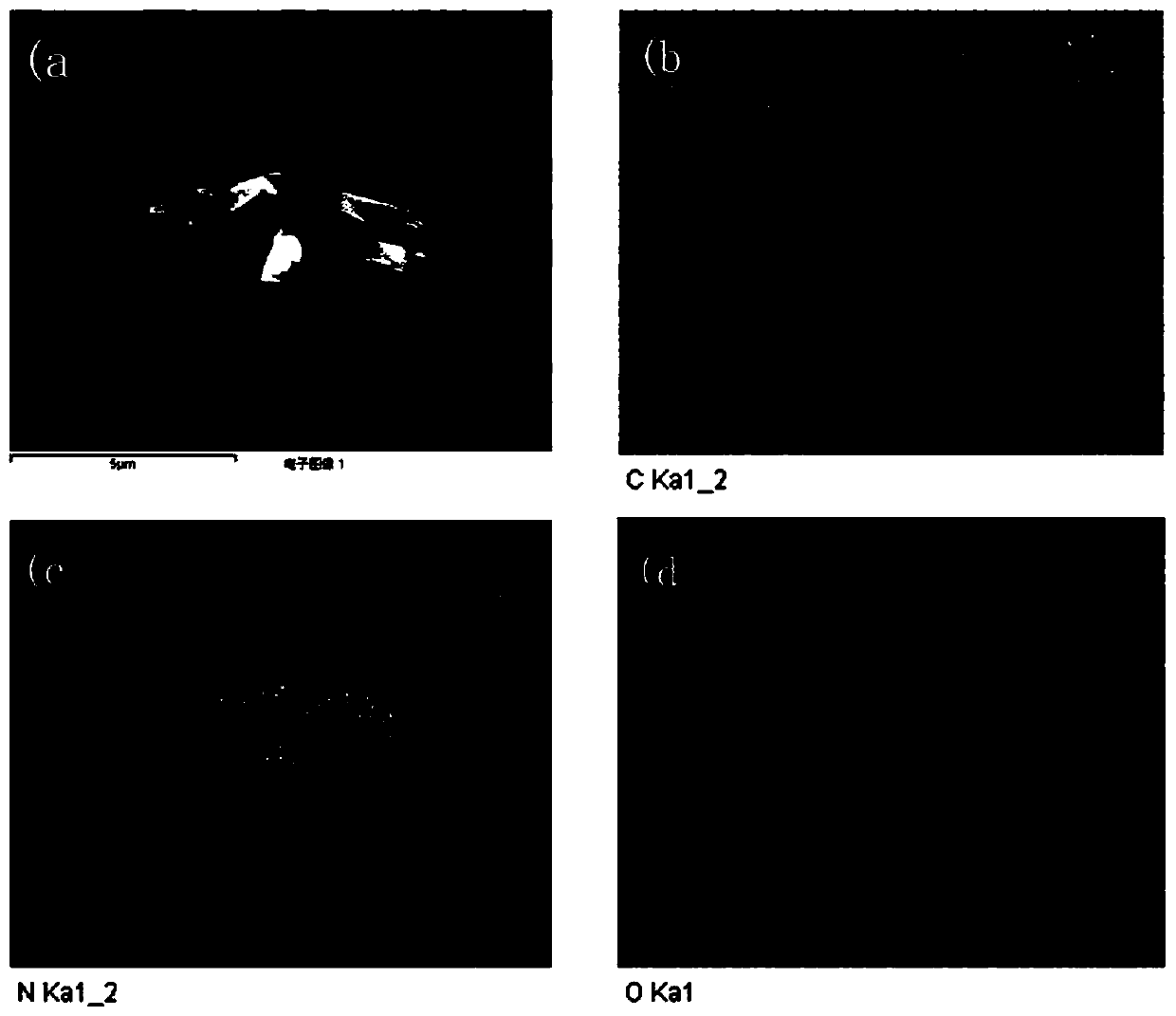

[0056] The product is analyzed by XRD, FSEM, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com