Ferro-manganese composite pillared clay mineral material and preparation method for treating thallium in wastewater

An iron-manganese composite and pillared clay technology is applied in the fields of iron-manganese composite pillared clay mineral materials and clay adsorption materials, which can solve the problems of difficult separation and large pressure drop, and achieve fast adsorption speed, low energy consumption, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing an iron-manganese composite pillared clay mineral material for treating thallium in wastewater, comprising the following steps:

[0045](1) Accurately weigh 0.845g of ferric chloride, 0.166g of sodium carbonate, 0.395g of potassium permanganate and 0.742g of manganese chloride, dissolve them in 50mL of deionized water respectively, then transfer them to a 100ml volumetric flask and constant volume Obtain ferric chloride solution, sodium carbonate solution, potassium permanganate solution and manganese sulfate solution respectively;

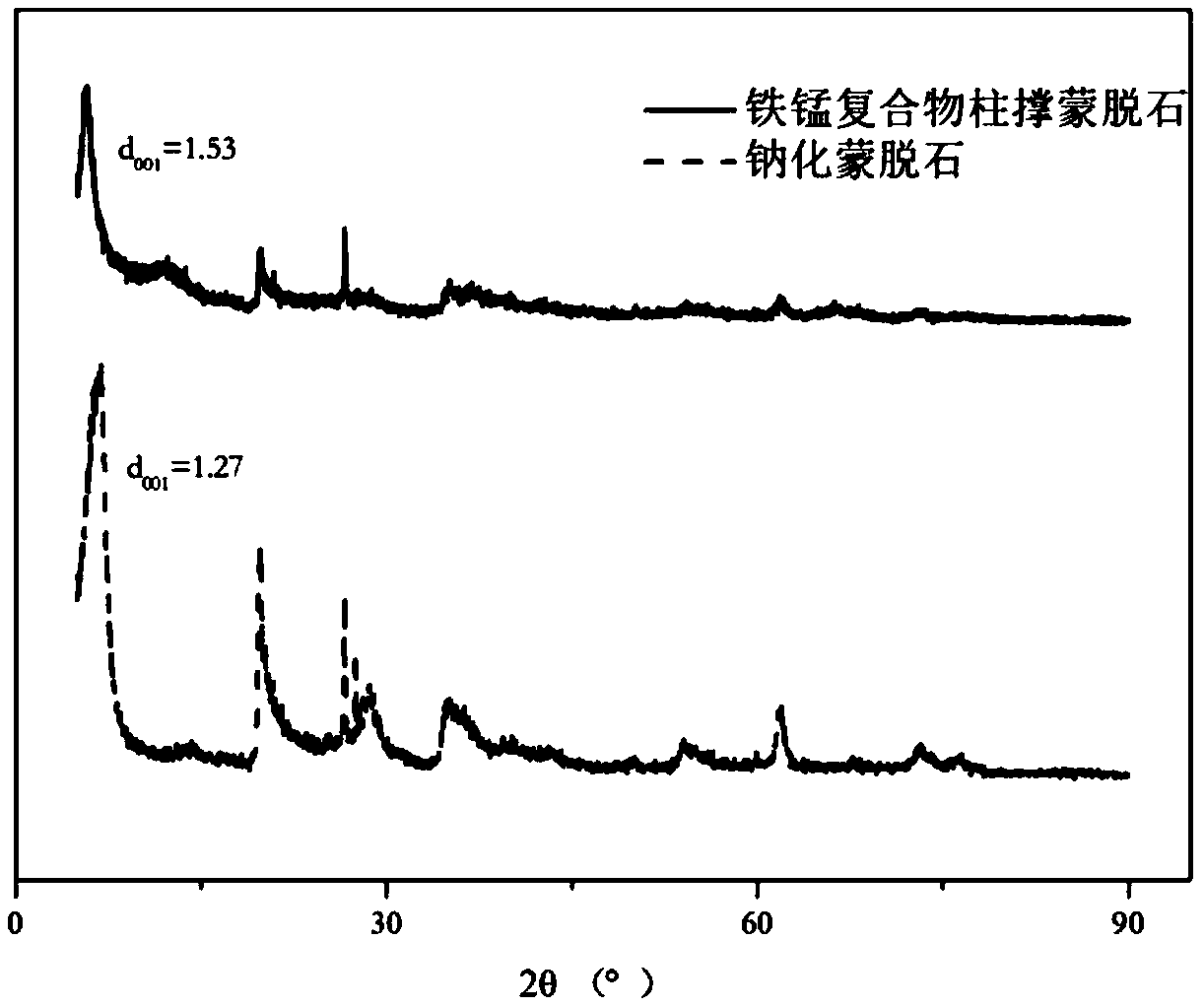

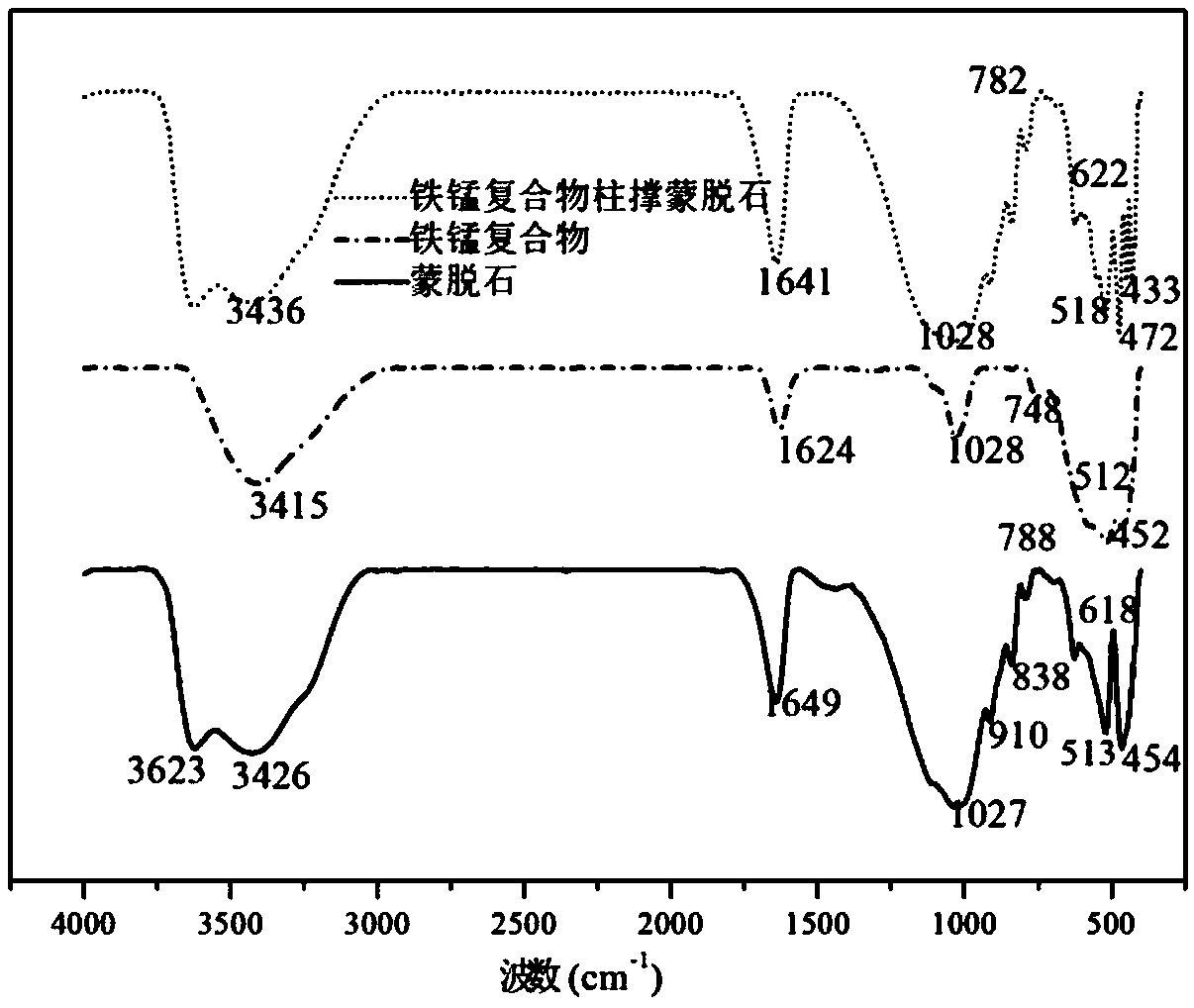

[0046] (2) The sodium carbonate solution is slowly dropped into the ferric chloride solution (the speed of dropping is 0.5mL / min), after the dropwise addition, it is aged at 60°C for 24 hours to obtain the aged product (colloidal reddish-brown Hydroxyl Iron Pillar Liquid) (i.e. iron-manganese complex, infrared spectrum as figure 2 shown);

[0047] (3) After washing the sodium montmorillonite with water, after dryin...

Embodiment 2

[0051] A method for preparing an iron-manganese composite pillared clay mineral material for treating thallium in wastewater, comprising the following steps:

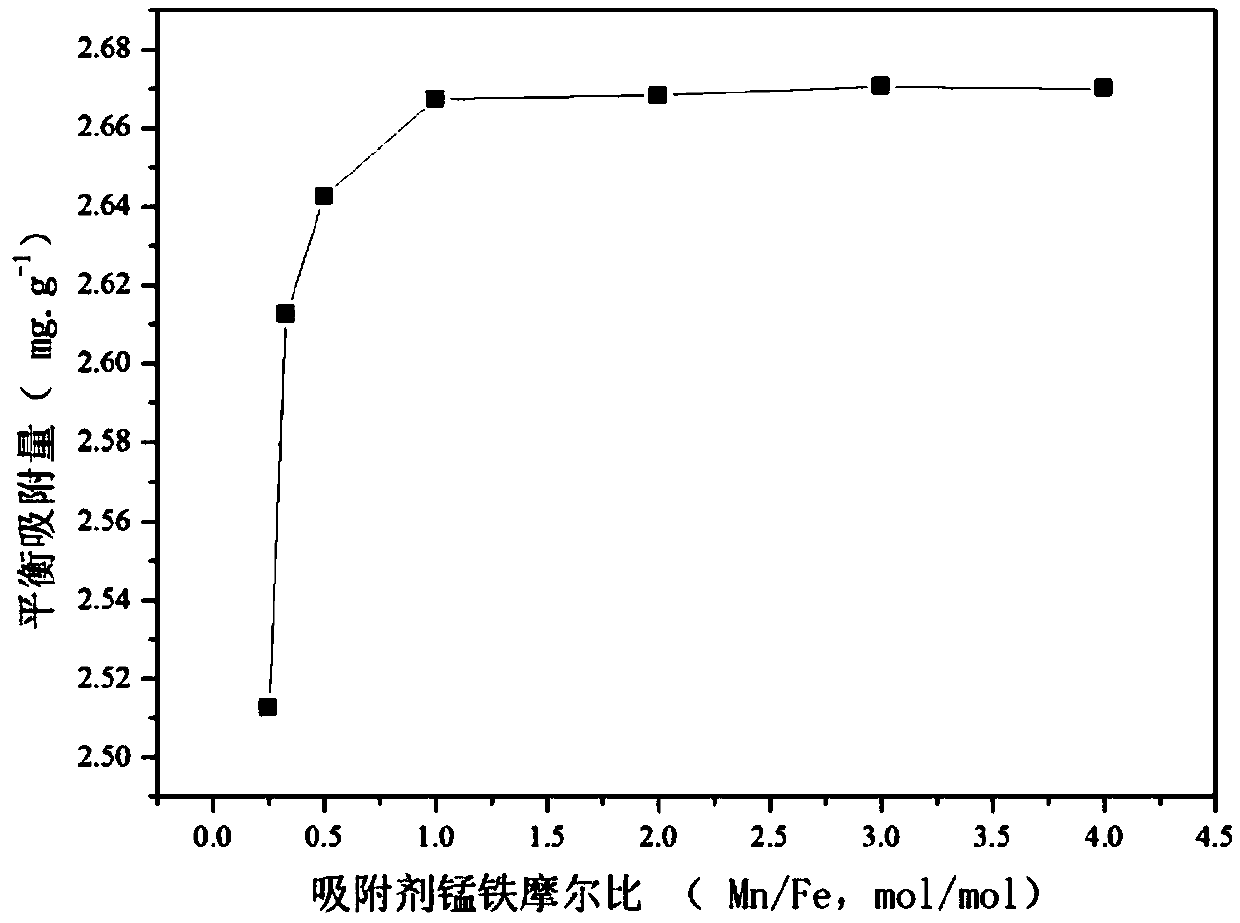

[0052] (1) According to the molar ratio of ferromanganese (Mn / Fe) is 4, 3, 2, 1, 1 / 2, 1 / 3 and 1 / 4, respectively, weigh the following 7 parts of raw materials: ① Accurately weigh 0.845g respectively Ferric chloride, 0.166g sodium carbonate, 0.792g potassium permanganate, 1.280g manganese sulfate and 3.125g sodium montmorillonite; ② Accurately weigh 0.845g ferric chloride, 0.166g sodium carbonate, 0.594g permanganate Potassium, 0.960g manganese sulfate and 3.125g sodium montmorillonite; ③accurately weigh 0.845g ferric chloride, 0.166g sodium carbonate, 0.396g potassium permanganate, 0.640g manganese sulfate and 3.125g sodium montmorillonite ; ④ accurately weigh 0.845g ferric chloride, 0.166g sodium carbonate, 0.198g potassium permanganate, 0.320g manganese sulfate and 3.125g sodium montmorillonite; ⑤ accurately weigh 1.69...

Embodiment 3

[0060] The iron-manganese composite pillared clay mineral material used to treat thallium in wastewater in this example is the iron-manganese composite pillared clay mineral material prepared in Example 2 with a manganese-iron molar ratio of 1.

[0061] Put different contents of iron-manganese composite pillared clay mineral materials (dosage: 0.1, 0.2, 0.4, 0.6, 0.8, 1, 2 and 4g / L) into 50ml centrifuge tubes respectively, and pipette them into the centrifuge tubes respectively. Take 25mL prepared 1mg L -1 Tl(I) solution, mixed well, placed on a water bath shaker at 30±1°C for 24 hours, centrifuged, and the supernatant was passed through a 0.45 μm filter membrane, and the concentration of Tl(I) in the solution was measured by an atomic absorption spectrophotometer. concentration. The results test as Figure 4 shown. Figure 4 In Example 3, it is a graph showing the influence of the dosage on iron-manganese composite pillared clay mineral material except for Tl(I).

[0062]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com