Blast furnace gas comprehensive treatment and recovery method

A technology of comprehensive treatment and recovery method, which is applied in the field of comprehensive treatment and recovery of blast furnace gas, which can solve the problems of direct air discharge and large gas release without a good treatment method, and achieve the effects of reducing corrosion, reducing floor space, and reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

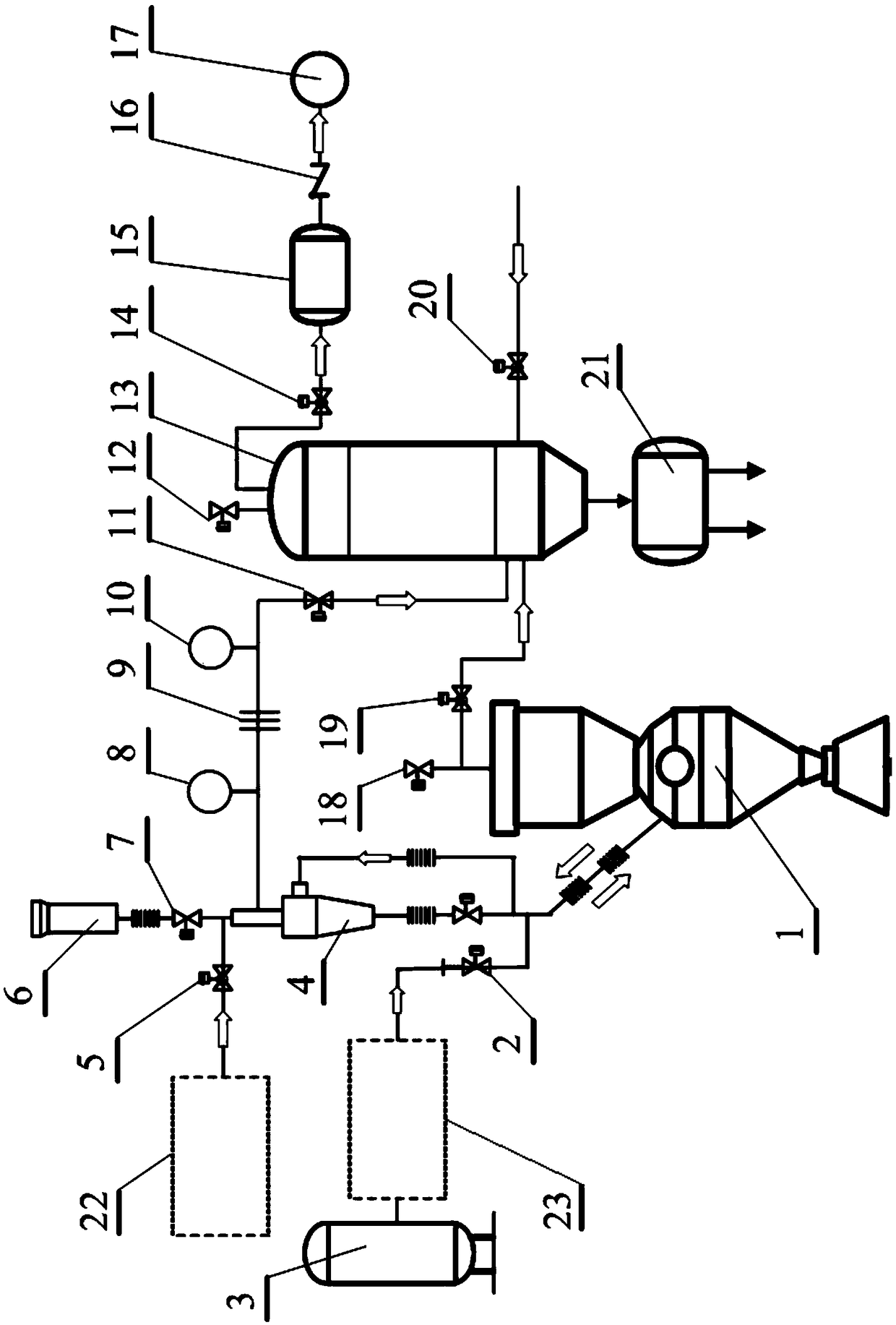

[0031] A method for comprehensive treatment and recovery of blast furnace gas, comprising the following steps:

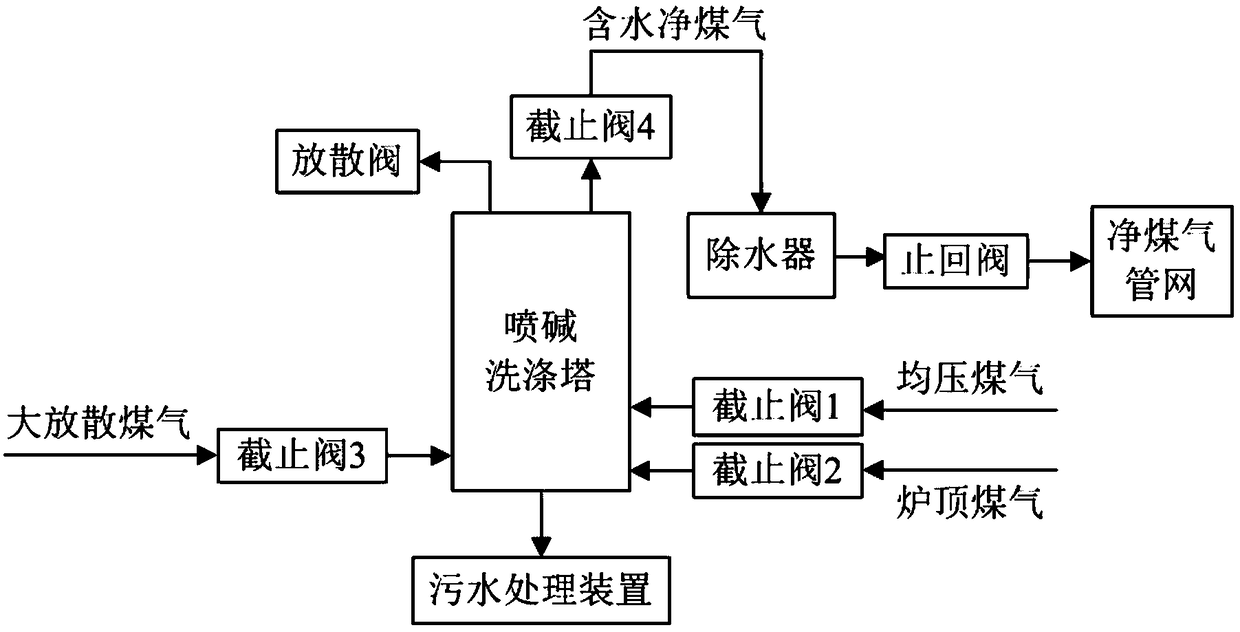

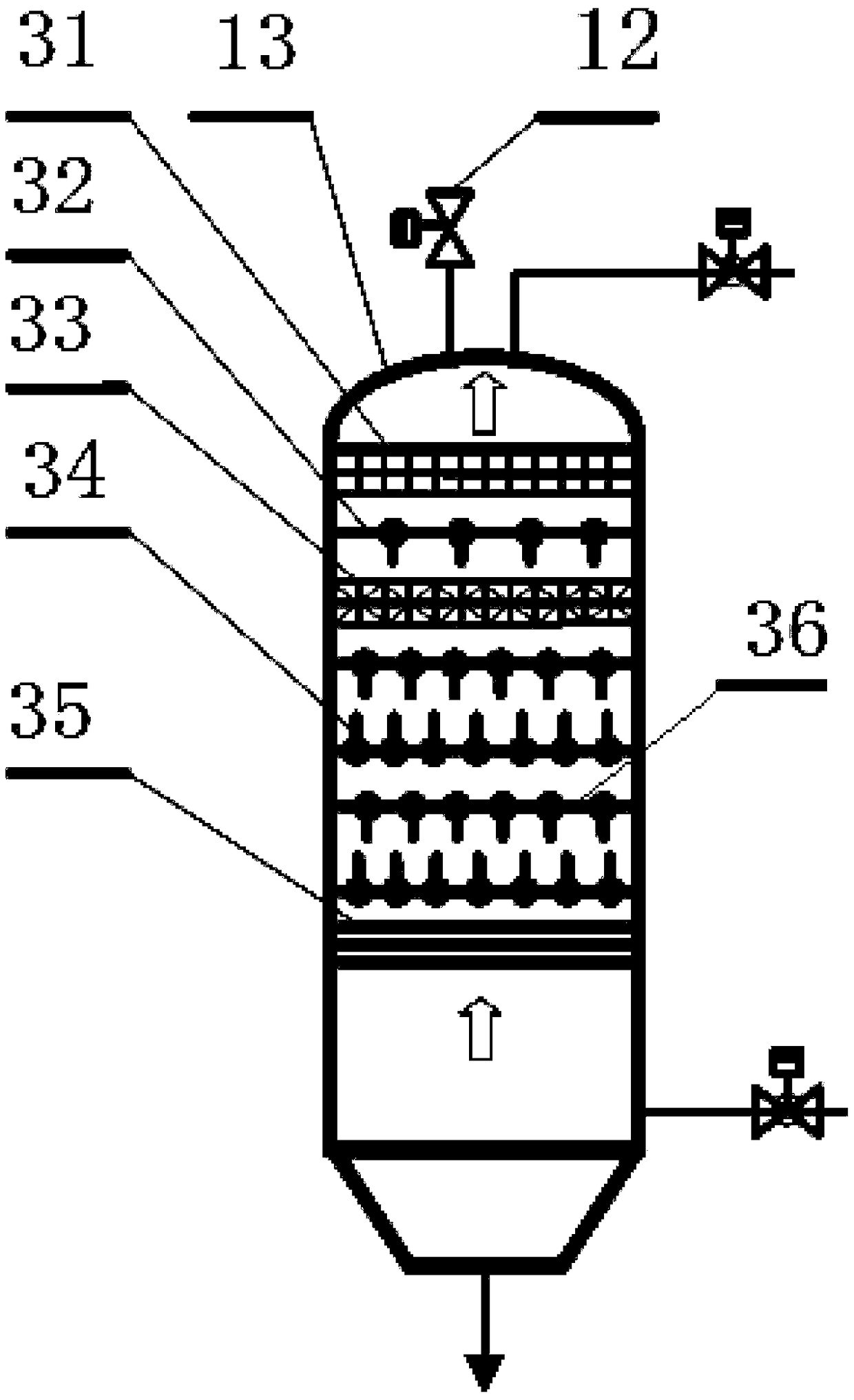

[0032] Step 1. The large diffused gas produced by the blast furnace enters the alkali-spraying scrubber 13 through the diffused gas recovery pipeline, the pressure-equalizing gas produced by the blast furnace enters the alkali-spraying scrubber 13 through the pressure-equalizing gas recovery pipeline, and the furnace top gas produced by the blast furnace passes through the furnace top gas The recovery pipeline enters the alkali-spraying scrubber 13, and the large diffused gas, pressure-equalizing gas and furnace top gas form a mixed gas in the alkali-spraying scrubber 13;

[0033] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com