Method for improving installation precision and construction progress of assembled precast box culvert

A technology for installation accuracy and construction progress, which is applied in the field of improving the installation accuracy and construction progress of prefabricated box culverts, and can solve the problems of low installation accuracy and long construction period of prefabricated box culverts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

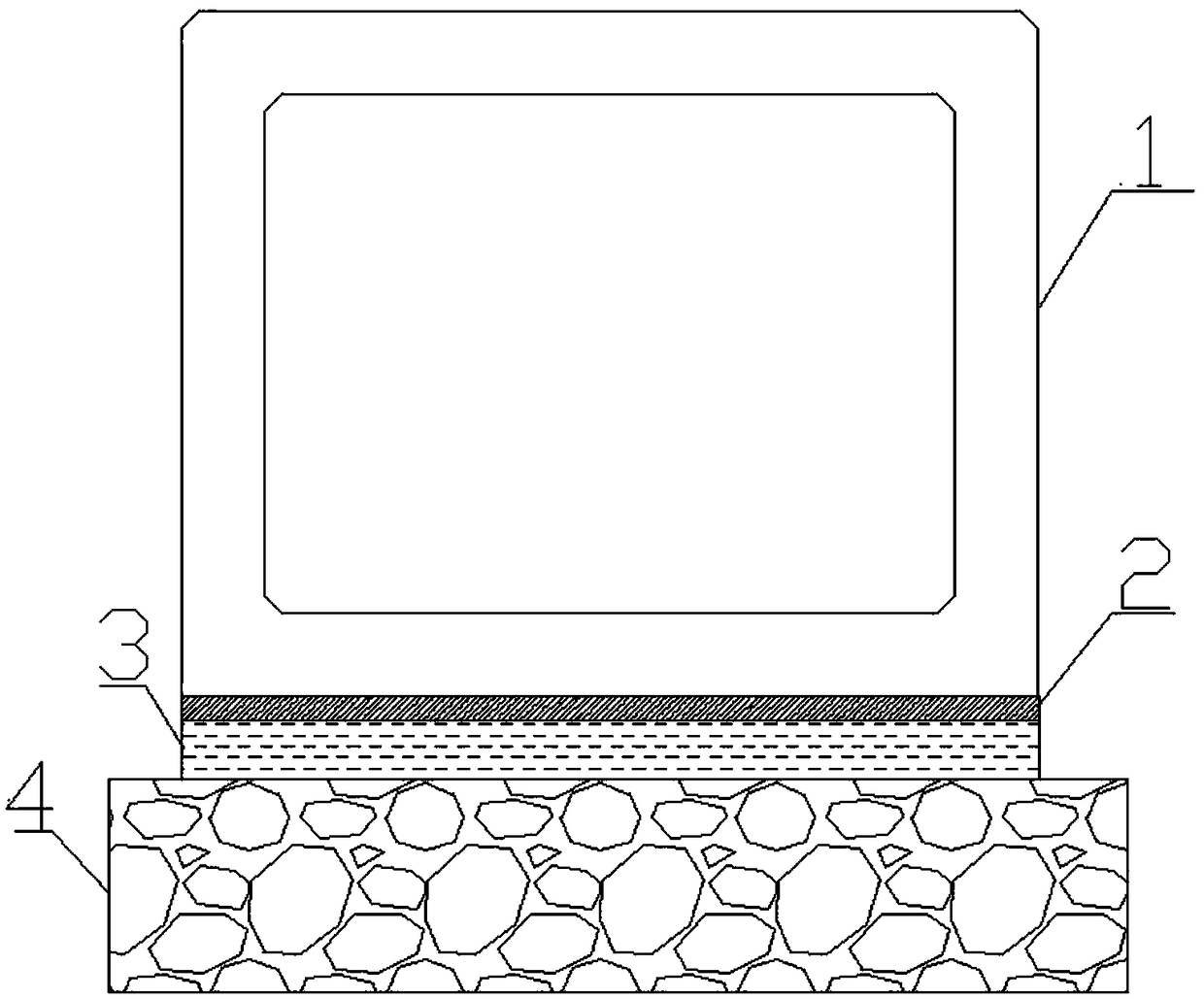

[0024] Prefabricated box culvert, also called assembled box culvert, is a prefabricated box-shaped structure of reinforced concrete, which can be used as a large-scale flood discharge channel, urban rainwater and sewage pipeline, large-scale water storage tank, comprehensive pipe gallery, underground pedestrian passage, underground motor vehicle Tunnels, small garages and other municipal construction environments. The most common shape of prefabricated box culverts is square, but in addition to square box culverts, there are also rectangular and U-shaped box culverts based on square box culverts according to use requirements, force conditions, address basis, construction and manufacturing conditions, etc. Cover board, two U-shaped splicing, one side or upper and lower arches, single hole or multi-hole culvert and other shapes. Compared with cast-in-place construction, the prefabricated prefabricated box culvert 1 can shorten the construction time and promote civilized and gree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com