Filling, sand prevention and steam injection integrated device and operating method using same

A technology of sand control and steam injection, which is applied in the field of oil and gas exploration and development, can solve problems such as failure to meet high temperature and high pressure sealing requirements, increase safety hazards, and easy failure of filling tools, so as to ensure the quality of filling sand control and construction safety, reduce construction period and Operating cost, the effect of ensuring safe and long-term production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0039] In the present application, the term "upstream" refers to the direction towards the upper joint 1 , and "downstream" refers to the direction towards the flush pipe joint 34 .

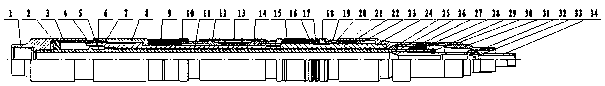

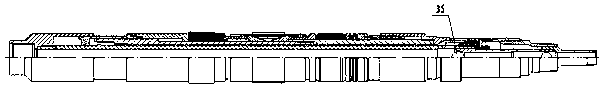

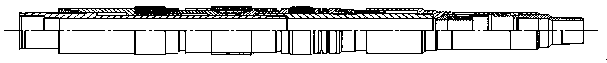

[0040] figure 1 It is a schematic diagram of the mechanism of the integrated device of filling, sand control and steam injection of the present invention. An integrated device for filling, sand control and steam injection, comprising a filling inner pipe, a filling outer pipe, a first sealing unit and a second sealing unit;

[0041] The filling inner tube includes the upper joint 1, the connecting pipe 5, the hollow valve sleeve 32 and the flushing pipe joint 34 connected in sequence, and the first piston 2 is also arranged in the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com