Hydrostatic slide device

A technology of hydrostatic pressure and slider, which is applied in the direction of hydrostatic bearings, liquid cushion bearings, bearings, etc., and can solve the problem of inability to adjust the oil pressure and maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

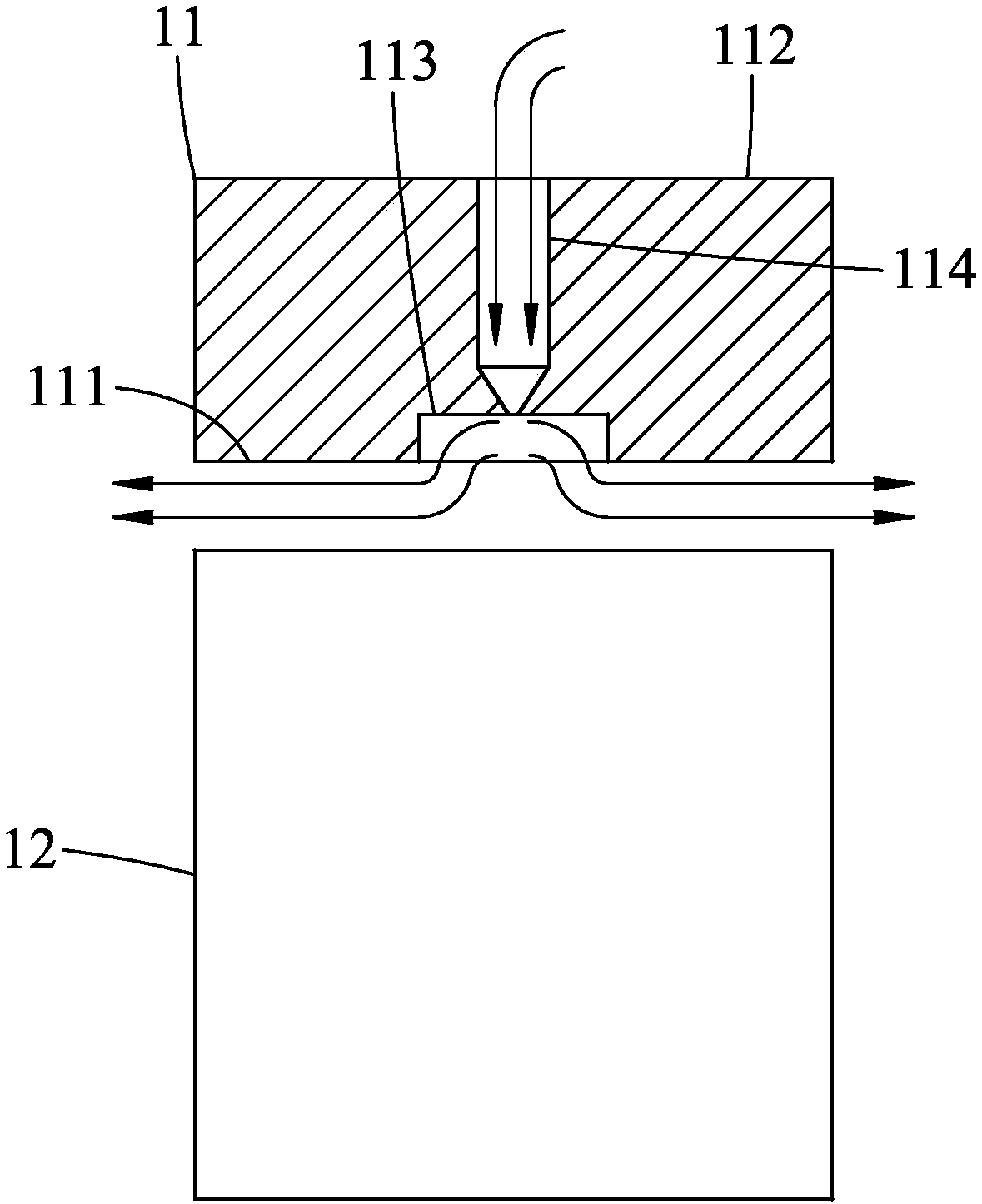

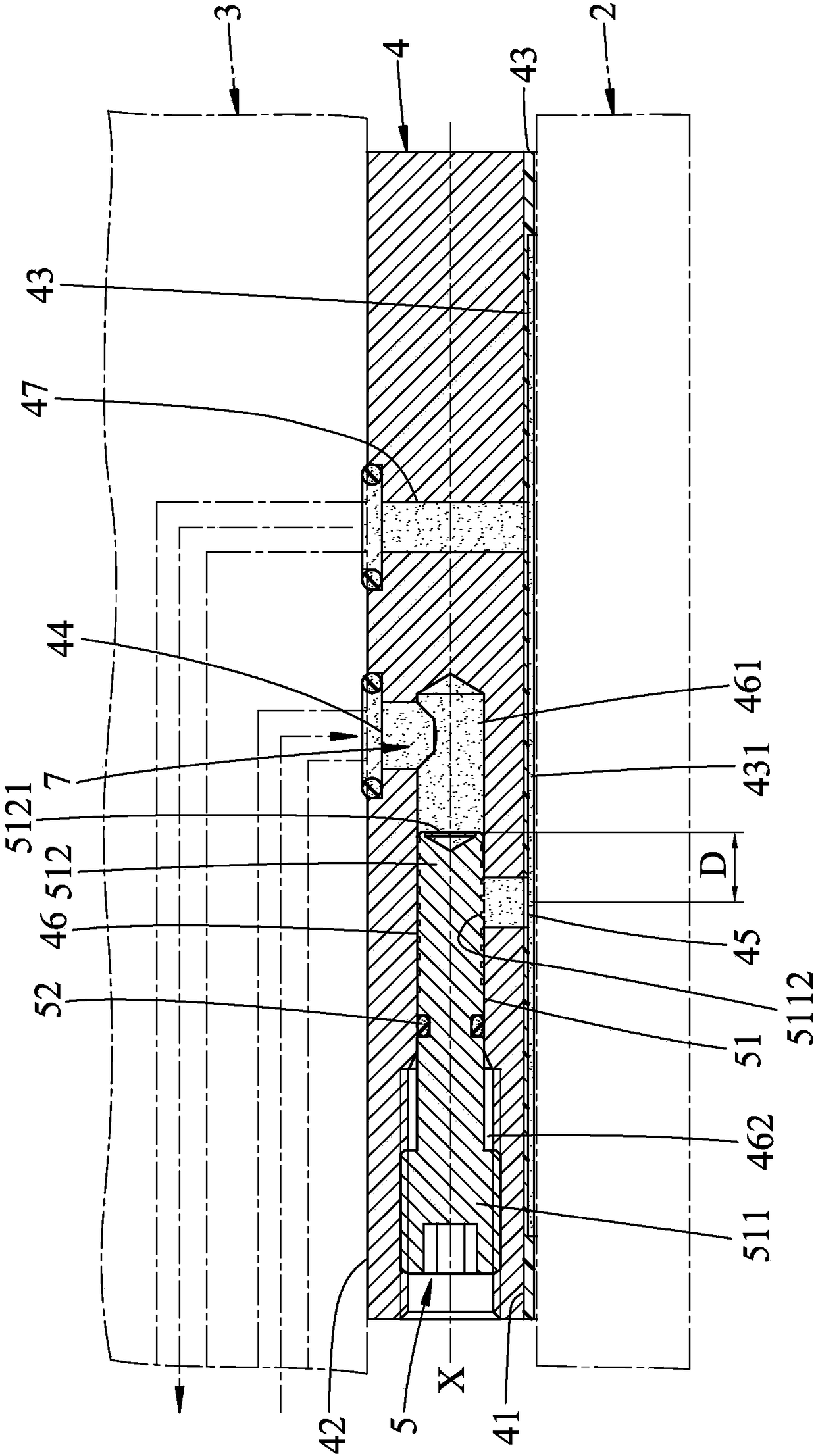

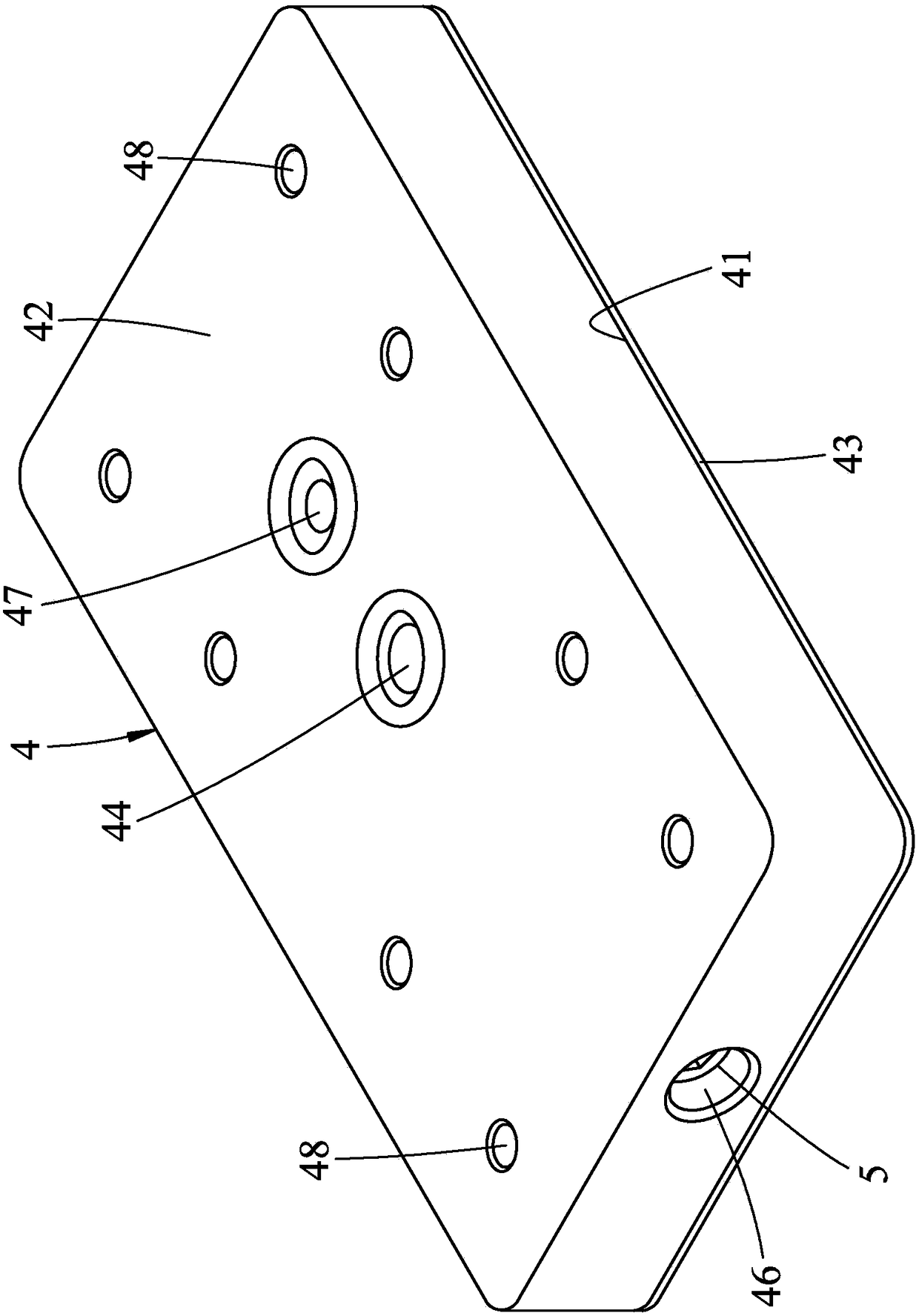

[0024] refer to figure 2 , image 3 and Figure 4 , an embodiment of the hydrostatic slider device of the present invention, slides on a slide rail 2 and carries a workbench 3 . The hydrostatic slider device includes a slider 4 and a capillary restrictor 5 .

[0025] The slider 4 includes a sliding surface 41 facing the slide rail 2, an engaging surface 42 opposite to the sliding surface 41 and facing the workbench 3, and a wear-resistant surface formed on the sliding surface 41. Layer 43, an inlet 44 formed on the joint surface 42 and used to introduce the lubricating fluid 7, an outlet 45 formed on the sliding surface 41 and used to release the lubricating fluid 7, a throttle hole 46, a pressure A detection hole 47 , and a plurality of locking holes 48 extending from the joint surface 42 toward the sliding surface 41 .

[0026] The wear-resistant layer 43 is a polymer resin material with a friction coefficient less than 0.2, with a thickness of about 2-4 mm, and has a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com