Displacement sensor with refractor and capable of improving magnification times and measurement method thereof

A displacement sensor and magnification technology, which is applied in the field of measurement, can solve the problems such as the sensor magnification is easily affected and the measurement accuracy drops, and achieves the effects of continuous displacement measurement, improving measurement accuracy, and solving the limitation of magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

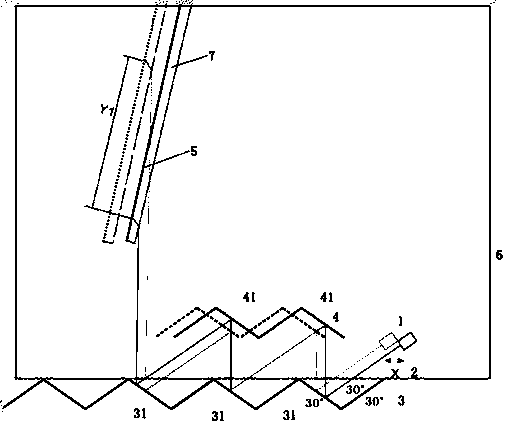

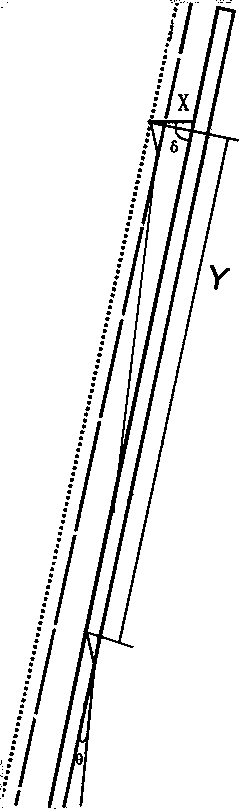

[0046] see figure 1 In this embodiment, a displacement sensor with a refracting mirror that can increase the magnification is provided, including a laser source 1, a laser beam 2, a triangular wave reflector 3, and the triangular wave reflector 3 includes a reflective surface 31, and a reflector group 4 , The reflector group 4 includes a reflector 41 , a photodetector 5 , a casing 6 , and a refractor 7 .

[0047] In this new type of displacement sensor with a refracting mirror that can increase the magnification:

[0048]The laser source 1 emits the laser beam 2, and makes the laser beam 2 shoot to the first reflective surface 31 of the triangular wave reflector 3; the first reflector 41 of the mirror group 4 corresponding to the first reflective surface 31 is used to receive The laser beam 2 is reflected by the first reflective surface 31 of the triangular wave reflector 3, and the laser beam is reflected to the triangular wave reflector along the same path during the measu...

Embodiment 2

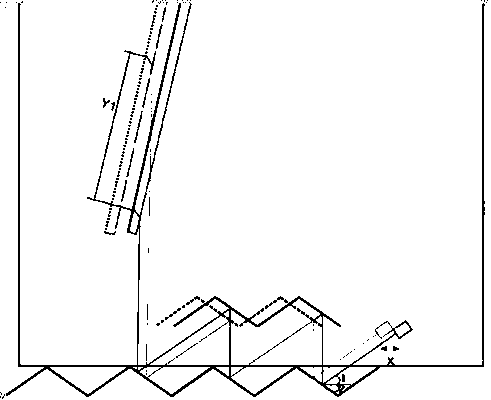

[0068] can refer to Figure 4 ,Such as Figure 4 As shown, compared with the displacement sensor with a refracting mirror that can increase the magnification in this embodiment and the displacement sensor that can increase the magnification with a refracting mirror described in Embodiment 1, the difference is that in this embodiment The multiple reflectors are directly connected to form an inline structure as a whole.

Embodiment 3

[0070] can refer to Figure 5 Compared with the displacement sensor with a refracting mirror that can increase the magnification in this embodiment and the displacement sensor that can increase the magnification with a refracting mirror described in Embodiment 2, the difference is that: provided in this embodiment The displacement sensor with a refracting mirror that can increase the magnification includes two reading heads, and the two reading heads have the same structure and are placed symmetrically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com