A dual-range current sensor for new energy vehicles

A current sensor and new energy vehicle technology, which is applied in the direction of changing the range circuit, measuring current/voltage, and only measuring current, etc., can solve the problems of measurement deviation from the set value, decrease of measurement accuracy, and heavy overall weight, etc., to achieve accuracy improvement , Reliability improvement, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with the accompanying drawings, embodiments of the present invention is further described.

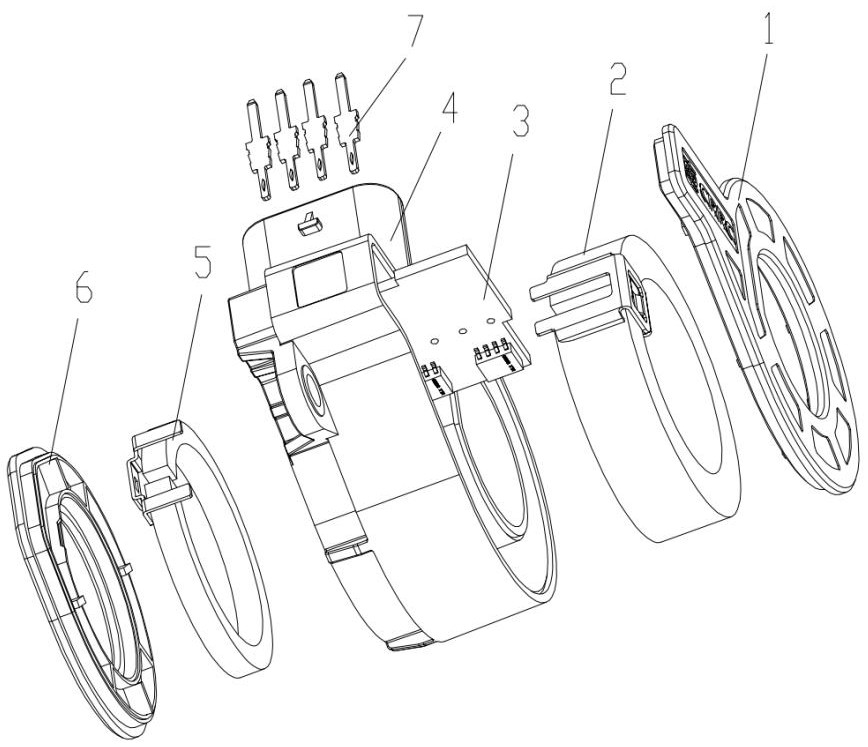

[0046] like Figure 1 Shown, a new energy automotive dual range current sensor, comprising a housing cover 1, a core assembly 2, comprising a Hall ASIC PCB assembly 3, a housing 4, two core assembly 5, two housing cover 6, 7 pin.

[0047] like figure 2 As shown in the core assembly 2 comprises a core 21, the core holder 22, the core holder 22 is fixed to core 21.

[0048] Of the iron core holder 22 comprises a topsheet 221 and side panels 222, 221 are fixed to the topsheet at two sides of the air gap core 21, the air gap is reduced to avoid core; side panels 222 disposed positioning portion 223, 223 against the positioning portion iron core 21 side, after the completion of assembly of the components on the housing mate with corresponding features, the position of the core to ensure the air gap in the housing.

[0049] like Figure 3 As shown in the printed circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com