A Control Method of Rigid-Flexible Coupling Motion Platform Based on Disturbance Force Measurement and Compensation

A control method, rigid-flexible coupling technology, applied in electric controllers, controllers with specific characteristics, adaptive control, etc., can solve the problems that LADRC cannot apply to high bandwidth requirements, is cumbersome, and is difficult to meet the needs of high-speed precision motion control , to achieve the effect of reducing the control complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the embodiment of the present invention, the rigid-flexible coupling platform mainly includes a mechanical guide rail, a frame rigid body, a flexible hinge, and a platform rigid body. Set X M ,X m are the displacements of the frame rigid body and the platform rigid body, respectively, are the velocities of the frame rigid body and the platform rigid body respectively, M and m are the masses of the frame rigid body and the platform rigid body respectively, k and c are the stiffness and damping of the flexible hinge respectively, F M , F m are the driving force of the driving unit acting on the frame rigid body and the platform rigid body respectively, f μ is the friction force between the frame rigid body and the mechanical guide rail.

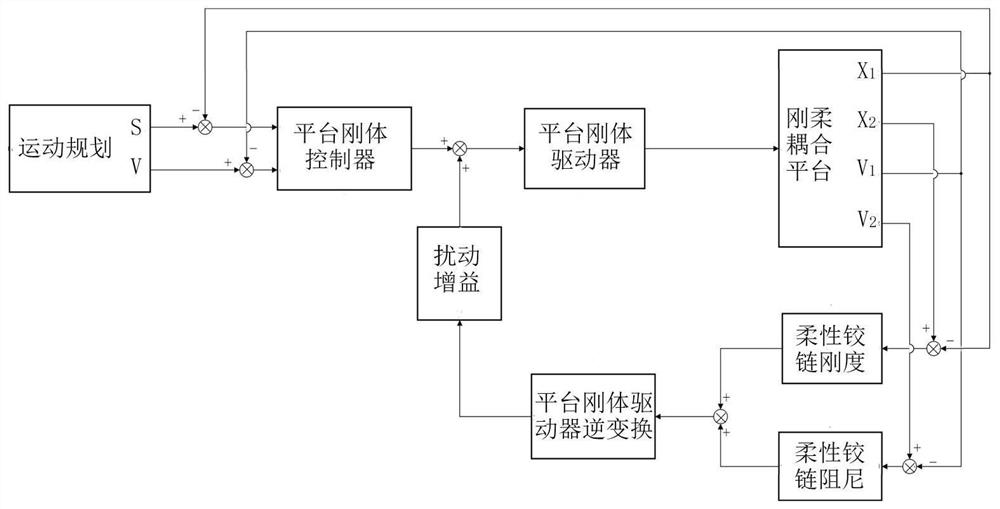

[0044]The rigid-flexible coupled motion platform control method based on disturbance force measurement and compensation in this embodiment is single-drive motion control, where the mechanical response equation of the rigid body mo...

Embodiment 2

[0056] In the embodiment of the present invention, the rigid-flexible coupling platform mainly includes a mechanical guide rail, a frame rigid body, a flexible hinge, and a platform rigid body. Set X M ,X m are the displacements of the frame rigid body and the platform rigid body, respectively, are the velocities of the frame rigid body and the platform rigid body respectively, M and m are the masses of the frame rigid body and the platform rigid body respectively, k and c are the stiffness and damping of the flexible hinge respectively, F M , F m are the driving force of the driving unit acting on the frame rigid body and the platform rigid body respectively, f μ is the friction force between the frame rigid body and the mechanical guide rail.

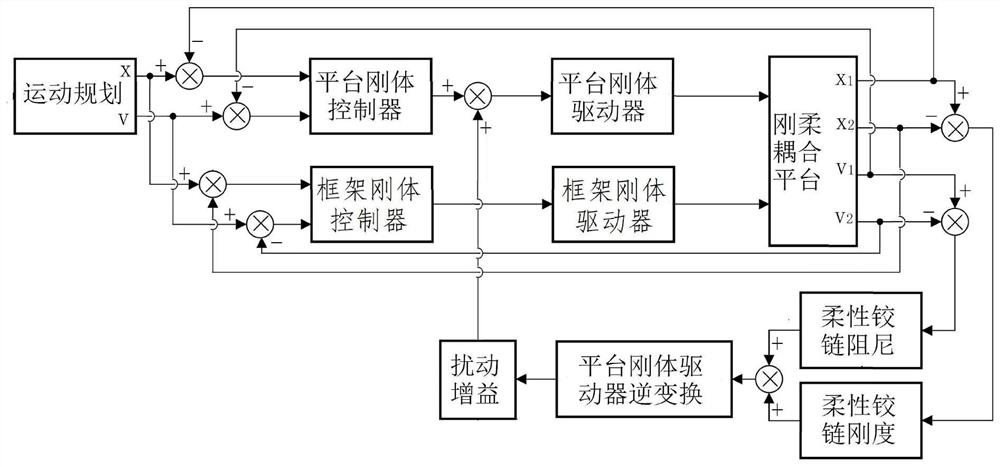

[0057] The rigid-flexible coupled motion platform control method based on disturbance force measurement and compensation in this embodiment is dual-drive motion control, where the mechanical response equation of the rigid body mot...

Embodiment 3

[0070] The platform parameters of this embodiment are:

[0071] Core platform quality m 2kg Frame quality M 2kg coefficient of friction 0.2 Flexible hinge stiffness k 2000N / mm Flexible hinge damping c 100N / mm / s Optimized Kp 35702280.82 Optimized Ki 7172.72 Optimized Kd 349977.10

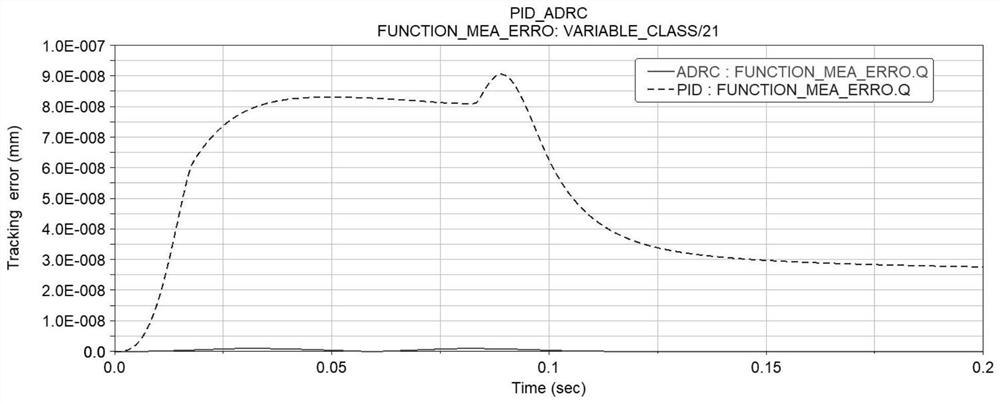

[0072] see Figure 2 to Figure 4 , when using the traditional PID method and the ADRC method using spring damping force compensation, the position tracking error curve is compared as figure 2 As shown, the maximum error drops from 9e-8 to 9e-9, an order of magnitude reduction.

[0073] When using PID control, if the model parameters change, the tracking error will change accordingly, such as image 3 Shown, yet adopt the active disturbance rejection control (ADRC) method of the technical scheme of the present invention of spring damping force compensation, the tracking error hardly changes with the model change, shows good disturbance re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com