An intelligent building express logistics device

A building and logistics technology, applied in logistics, coin-operated equipment and instruments for distributing discrete items, etc., can solve the problems of wasting time, aggravating the frequency of elevator round-trips, etc., to ensure safety, reduce delivery or pick-up time, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

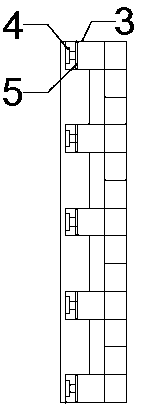

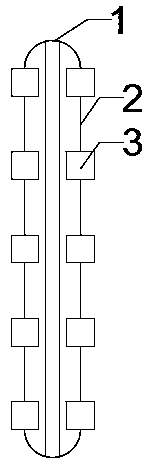

[0026] A building intelligent express logistics device, such as figure 1 , figure 2 As shown, it includes a longitudinal conveying mechanism and a delivery port. The longitudinal conveying mechanism includes a conveyor 1. The conveyor 1 is arranged in a channel reserved in the building, and a load-bearing column is arranged in the channel. The conveyor 1 is arranged along the load-bearing column; the conveyor 1 includes a conveying motor, a conveying chain 2, and an express temporary storage box 3, and the conveying motor is arranged on the load-bearing column, and the conveying chain 2 is provided with several express temporary storage boxes 3. The express temporary storage box 3 is articulated with the conveyor chain 2, the express temporary storage box 3 is vertically arranged on the conveyor chain 2, and the conveying motor drives the conveyor chain 2 to run, and drives the express delivery temporary storage box 3 to run , the express temporary storage box 3 is provided ...

Embodiment 2

[0030] This embodiment is further optimized on the basis of embodiment 1, as Figure 4 As shown, the express delivery port includes a pick-up port 6 and a mail port 7, and the pick-up port 6 and the mail port 7 are isolated from each other, and the distance between the pick-up port 6 and the mail port 7 is 20 km from the conveyor. 1. The distance between two express temporary storage boxes 3 on the left and right; Same; The periphery of the opening of the express temporary storage box 3 is provided with a magnet, and the opening of the corresponding express delivery temporary storage box 3 of the pick-up mouth 6 and the mail opening 7 is provided with an electromagnet, and the pick-up mouth 6 and The delivery port 7 accepts the express temporary storage box 3; it also includes an operating platform, the operating platform is respectively arranged on one side of the pick-up port 6 or the sender port 7, and the operating platform of the pick-up port 6 is provided with a digital ...

Embodiment 3

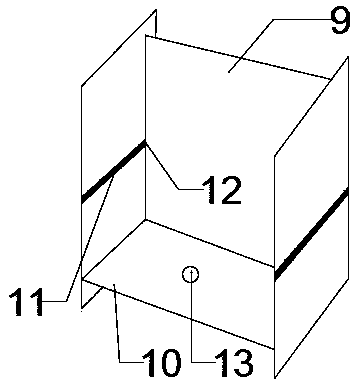

[0034] This embodiment is further optimized on the basis of Embodiment 2. The force bearing plate 5 includes a force bearing plate 9 and an object bearing plate 10, and the two ends of the force bearing plate 9 are respectively slidably connected with the inner wall of the express temporary storage box 3 , the force plate 9 is arranged parallel to the end face of the electric push rod 4, and the electric push rod 4 is in contact with one side of the force plate 9, and the force plate 9 is vertically fixed at the bottom of the side away from the electric push rod 4 The object plate 10, the upper surface of the object plate 10 is provided with a pressure sensor. The present invention enables the electric push rod 4 to act directly on the force plate 9 through the setting of the force plate 9, and the object plate 10 vertically fixed on the other side of the force plate 9 enables the object plate 10 to extend Out to the mail port 7 or the pick-up port 6, making it more convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com