Rapid Internalization Process of Tube Colloidal Battery

A colloidal battery and internalization technology, which is applied in secondary batteries, electrochemical generators, secondary battery charging/discharging, etc., can solve the difficulty of internalization of tubular batteries, the large demand for internalization, and the difficulty of increasing internalization and other problems, to achieve the effects of shortening the formation time, high conversion efficiency, and improving the internal formation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Taking the 560Ah tubular gel battery as an example, the rapid internalization process is further described, including the following steps:

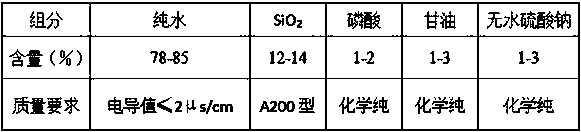

[0076] In the first step, pure water and sulfuric acid are used to mix and prepare two electrolytes with different densities for internalization, which are high-density electrolyte and low-density electrolyte; among them, the density of the low-density electrolyte is 1.03-1.05g / cm 3 , the density of the high-density electrolyte is 1.30-1.36g / cm 3 .

[0077] The second step is to pour the low-density electrolyte into the tubular colloidal battery through an acid cycle machine, let it stand for 1-2 hours, and then charge it with a small current of 5.6A to 28A for 1-2 hours.

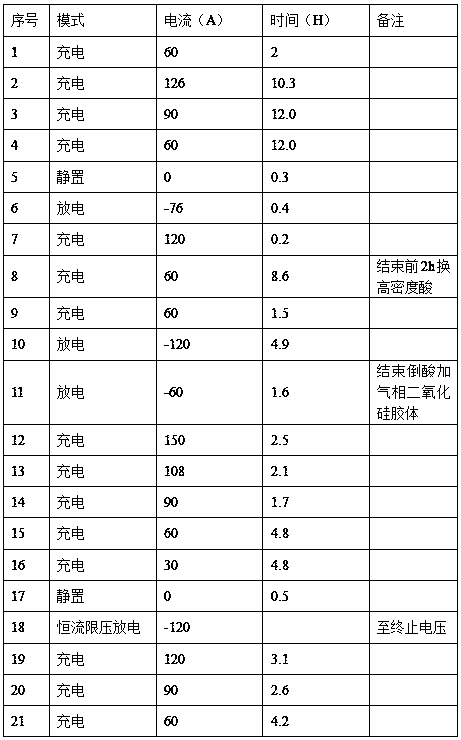

[0078] In the third step, charge and discharge according to the charge and discharge current and time given in Table 1 below:

[0079] Table 1:

[0080]

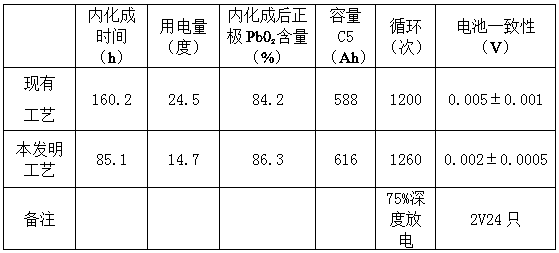

[0081] The 560Ah battery after the above-mentioned internalization was tested and compared with the b...

Embodiment 2

[0084] Taking the 400Ah tubular gel battery as an example, the rapid internalization process is further described, including the following steps:

[0085] In the first step, pure water and sulfuric acid are used to mix and prepare two electrolytes with different densities for internalization, which are high-density electrolyte and low-density electrolyte; among them, the density of the low-density electrolyte is 1.03-1.05g / cm 3 , the density of the high-density electrolyte is 1.30-1.36g / cm 3 ;

[0086] The second step is to pour the low-density electrolyte into the tubular gel battery through an acid cycle machine, let it stand for 1-2 hours, and then charge it with a small current of 4-20A for 1-2 hours;

[0087] The third step, the first stage of charging and discharging:

[0088] (1) Charging 1: charging current 8A ~ 16A, charging time 1.5h ~ 2.5h;

[0089] (2) Charging 2: charging current 24A~28A, charging time 9h~11h;

[0090] (3) Charging 3: charging current 16A~20A,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com