Oil liquid fungicidal formulation

A fungicide, oily liquid technology, applied in the field of fungicidal oily liquid preparations, can solve problems such as aggregation effect, agglomeration formation or suspension phase sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Preparations are prepared according to the following method:

[0095] Add Solvesso 200 (heavy aromatic naphthalene), N,N-dimethyldecylamide, TSP 16EO-tristyrylphenol ethoxylate and calcium dodecylbenzenesulfonate to the vessel. Under stirring, picoxystrobin and tebuconazole were added. While stirring, the mixture was heated to 70-75°C. Keep stirring until picoxystrobin and tebuconazole are completely dissolved. Turn off heat. While stirring, the n-butanol polyglycol ether and soybean oil methyl ester were added to the vessel. Mancozeb and micronized hexamethylenetetramine were then added to the mixture. Increase the stirring rate to 800 RPM. Stirring is continued until a completely homogeneous formulation is obtained.

[0096] Recipe I

[0097] Element

Embodiment 2

[0099] Preparations are prepared according to the following method:

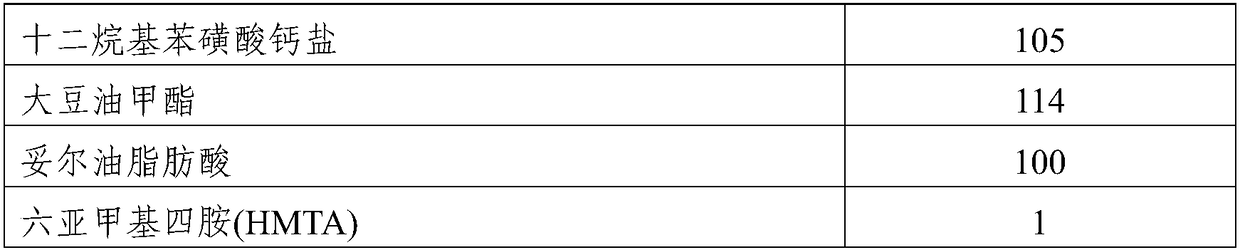

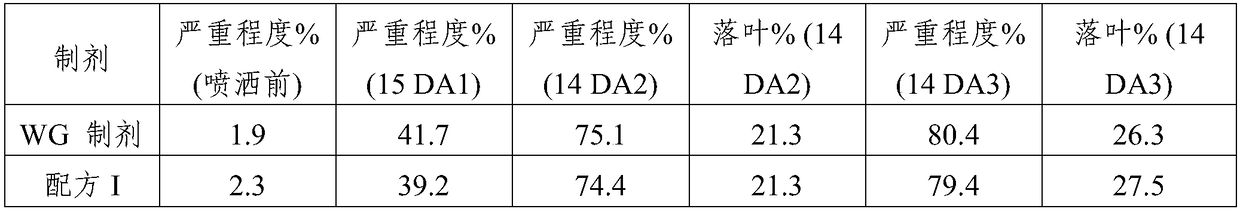

[0100] Add Solvesso 200 (heavy aromatic naphthalene), N,N-dimethyldecylamide, TSP 16EO-tristyrylphenol ethoxylate and calcium dodecylbenzenesulfonate to the vessel. Under stirring, picoxystrobin and tebuconazole were added. While stirring, the mixture was heated to 70-75°C. Keep stirring until the pyraclostrobin and tebuconazole are completely dissolved. Turn off heat. While stirring, add n-butanol polyglycol ether, soybean oil methyl ester and TOFA to the vessel. Mancozeb and micronized hexamethylenetetramine were then added to the mixture. Increase the stirring rate to 800 RPM. Stirring is continued until a completely homogeneous formulation is obtained.

[0101] Recipe II

[0102]

[0103]

Embodiment 3

[0105] Preparations are prepared according to the following method:

[0106] Solvesso 200 (heavy aromatic naphthalene), Tween 24, TSP 16EO-tristyrylphenol ethoxylate and calcium dodecylbenzenesulfonate were added to the vessel. Under stirring, picoxystrobin and tebuconazole were added. While stirring, the mixture was heated to 70-75°C. Keep stirring until picoxystrobin and tebuconazole are completely dissolved. Turn off heat. While stirring, the ethoxy-propoxylated alcohol, soybean oil methyl ester and TOFA were added to the vessel. Mancozeb, hexamethylenetetramine and defoamer are then added to the mixture. Increase the stirring rate to 800 RPM. Stirring is continued until a completely homogeneous formulation is obtained.

[0107] Formula III

[0108] Element

g / L

picoxystrobin

27

34

Mancozeb (85% A.I.)

470(400)

Solvesso Heavy Aromatic Naphthalene

145

Tween TM twenty four

141

TSP 16EO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com